A kind of construction method of yellow phosphorus electric furnace bottom

A construction method and technology of an electric furnace, applied in the construction field of the bottom of a yellow phosphorus electric furnace, can solve the problems of heavy roughening and masonry labor, high requirements for the quality of the furnace paste, and reduced life of the furnace bottom, etc., to achieve tight lap joints, The effect of low labor intensity and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

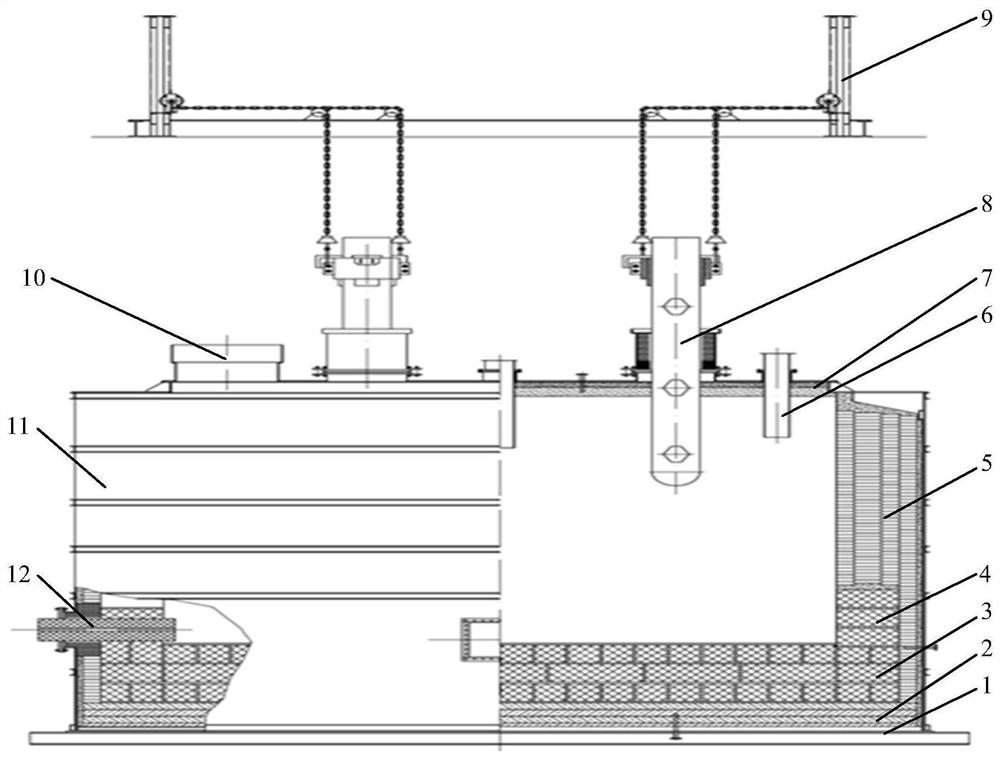

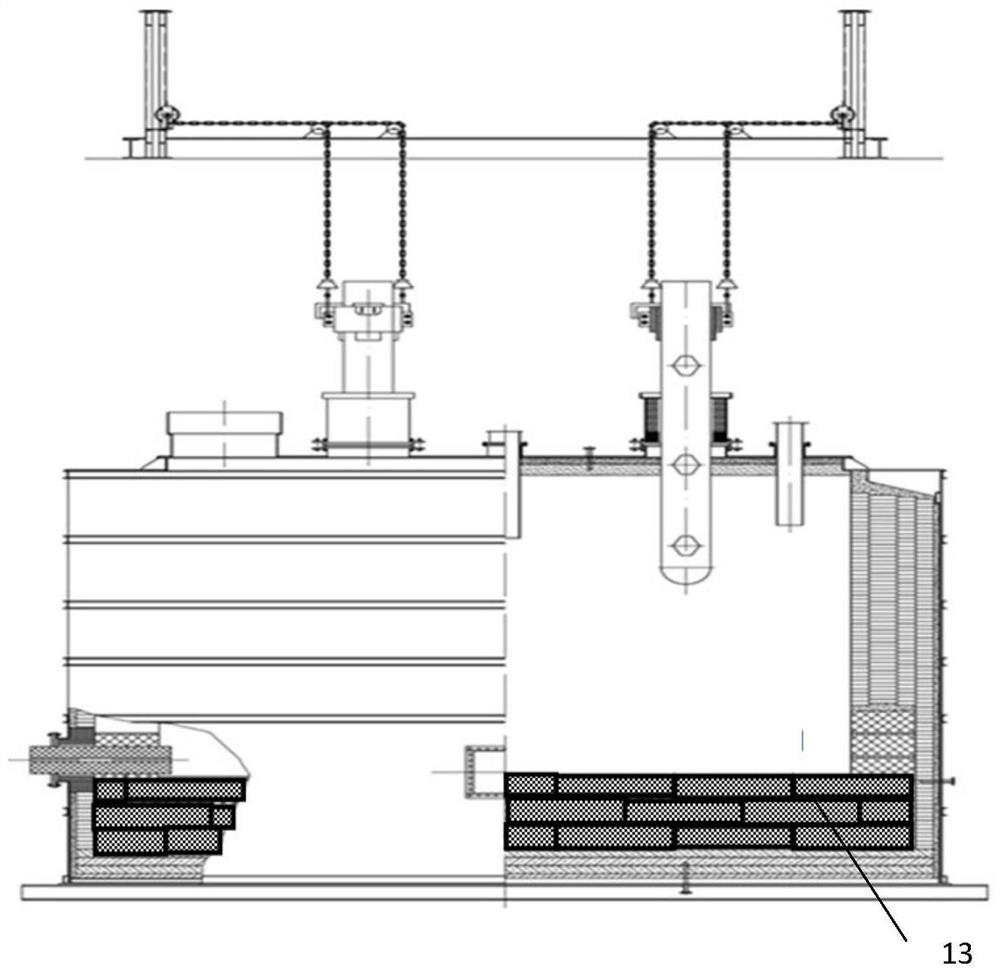

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

[0026] The present invention selects a graphite electrode with a mature technology of 400mm in the current market as the carbon material for the furnace bottom lining, is connected to the required length of the furnace bottom through a graphite threaded joint, and is stacked in three layers, and the surface is filled with electrode paste to level it. , the periphery of the furnace wall is compacted with traditional carbon bricks, and it becomes a graphite electrode type furnace bottom. The specific construction method includes the following steps:

[0027] (1) The carbon material at the bottom of the furnace is a graphite electrode with a diameter of 400mm, which is currently on the market. There are many manufacturers, the technology is mature, the quality is guaranteed, and the price is relatively low. At present, the largest graphite electrode with a diameter of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com