Lap joint type steel core cement fiberboard for floor heating and application method of lap joint type steel core cement fiberboard

A cement fiber board and steel core technology, which is applied in the field of balance layer materials for dry floor heating, can solve problems such as the temperature and transverse conduction speed of the board easily broken, and achieve the effects of energy saving and environmental protection of products and processes, small ground temperature difference, and accelerated thermal diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

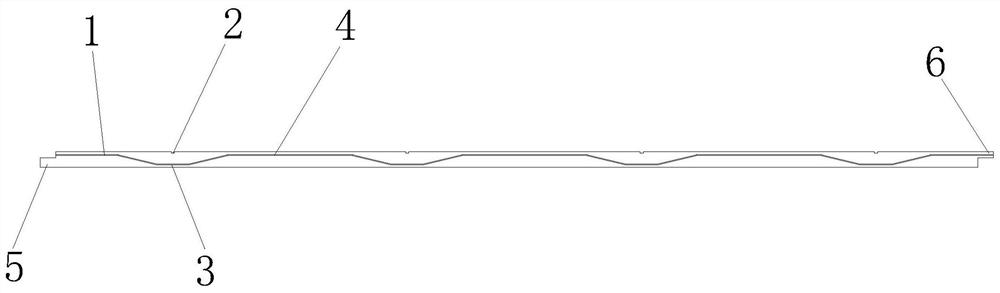

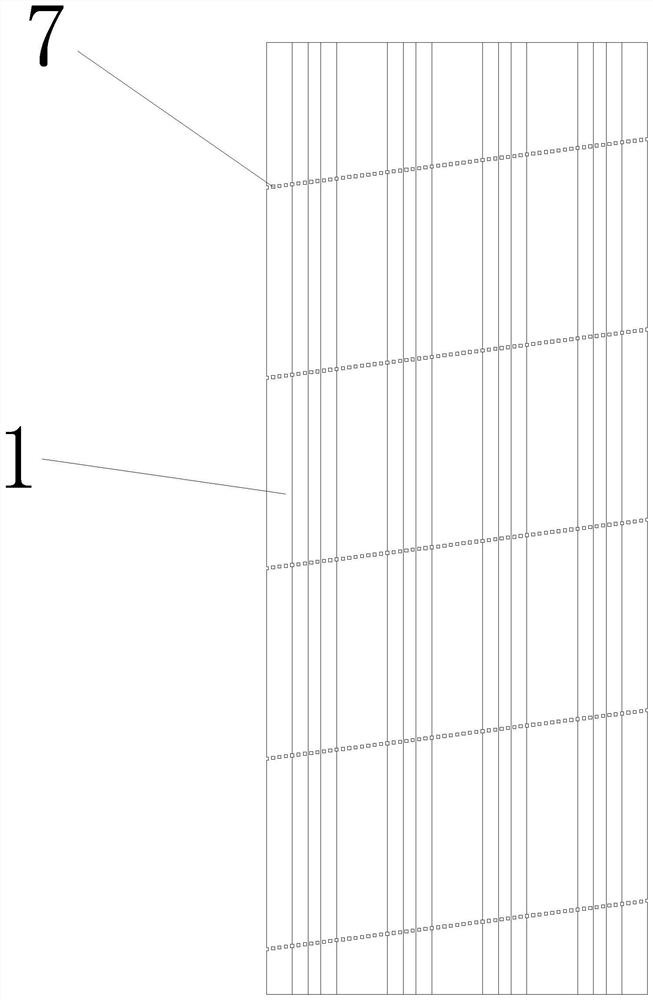

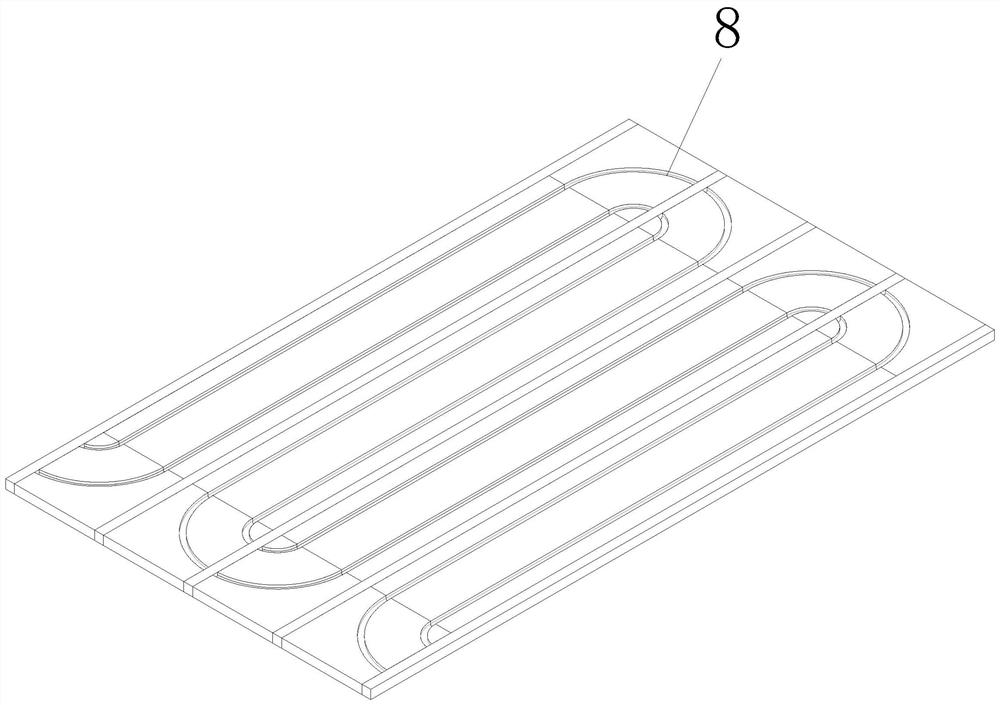

[0028] This embodiment proposes a lap joint type steel core cement fiberboard for floor heating, refer to figure 1 , molded by cement fiber board and steel plate 1, steel plate 1 is set inside the cement fiber board, steel plate 1 is corrugated, with 4 narrow planes 3 and 5 wide planes 4, narrow plane 3 is set near the bottom of cement fiber board, wide plane 4. Set it close to the cement fiber board. A groove 2 is provided at the position corresponding to the narrow plane 3 on the cement fiber board, and the groove 2 is used for positioning the floor heating pipe. refer to figure 2 , The steel plate 1 is provided with a number of through holes 7 . The effect of opening some through holes on the metal plate is to avoid the layered damage of the steel plate and the cement fiber board; the through holes 7 are arranged in 5 rows in parallel, and each row is slightly inclined to the bottom edge of the steel plate, which increases the space for the arrangement of the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com