Magnetic track breaker with composite working of permanent magnet and electromagnet

A magnetic rail brake and electromagnetic composite technology, which is applied in the direction of brakes interacting between brake components and rails, railway braking systems, railway car body parts, etc., can solve the problems of insensitive braking response, incomplete disconnection of braking force, The problem of excessive reverse torque of the rotating shaft can reduce the phenomenon of residual magnetism, enhance the braking effect and reduce the effect of reverse torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

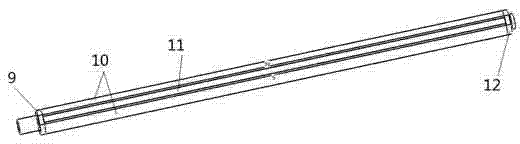

[0018] Such as image 3 As shown, the magnetic track brake has a rotating shaft 1, which is composed of two half shafts 10, a left shaft head 9, a right shaft head 12 and a permanent magnet 11 to form a circular shaft body. The two semi-shafts 10 are arranged opposite to each other, and an axially penetrating through groove is left in the middle of the two half-shafts 10. A permanent magnet 11 with the same size as the through groove is embedded in the through groove. The magnetization direction of the permanent magnet 11 is toward the two sides. The directions of the two semi-axes 10 are N pole and S pole respectively.

[0019] The left shaft head 9 is fixedly connected to the left ends of the two semi-shafts 10, the right shaft head 12 is fixedly connected to the right ends of the two half shafts 10, the left shaft head 9 has a long length, and is used to connect the driving mechanism for driving the rotating shaft 1, and the left Both the shaft head 9 and the right shaft h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com