Surfboard and its manufacturing process

A technology for surfboards and bottom plates, applied in special-purpose ships, ships, transportation and packaging, etc., can solve the problems of easy scrapping, short service life and low efficiency, and achieve simplified manufacturing process, long service life and good comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

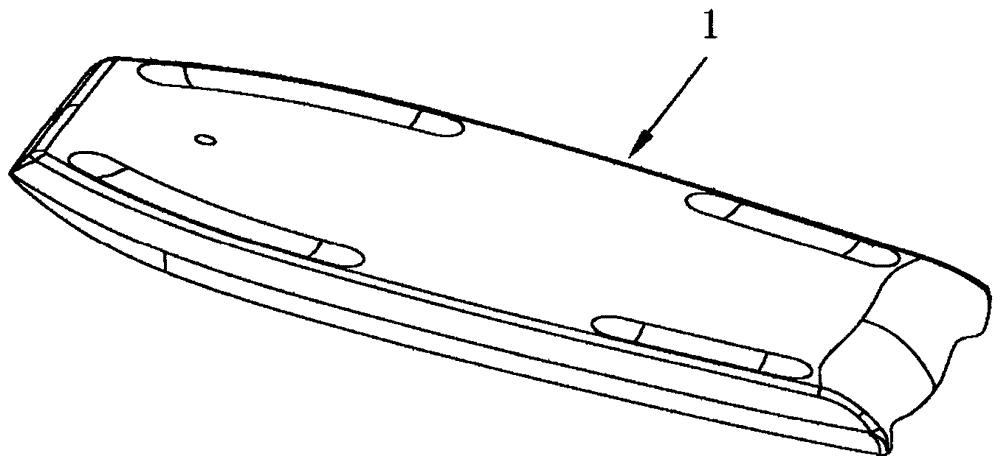

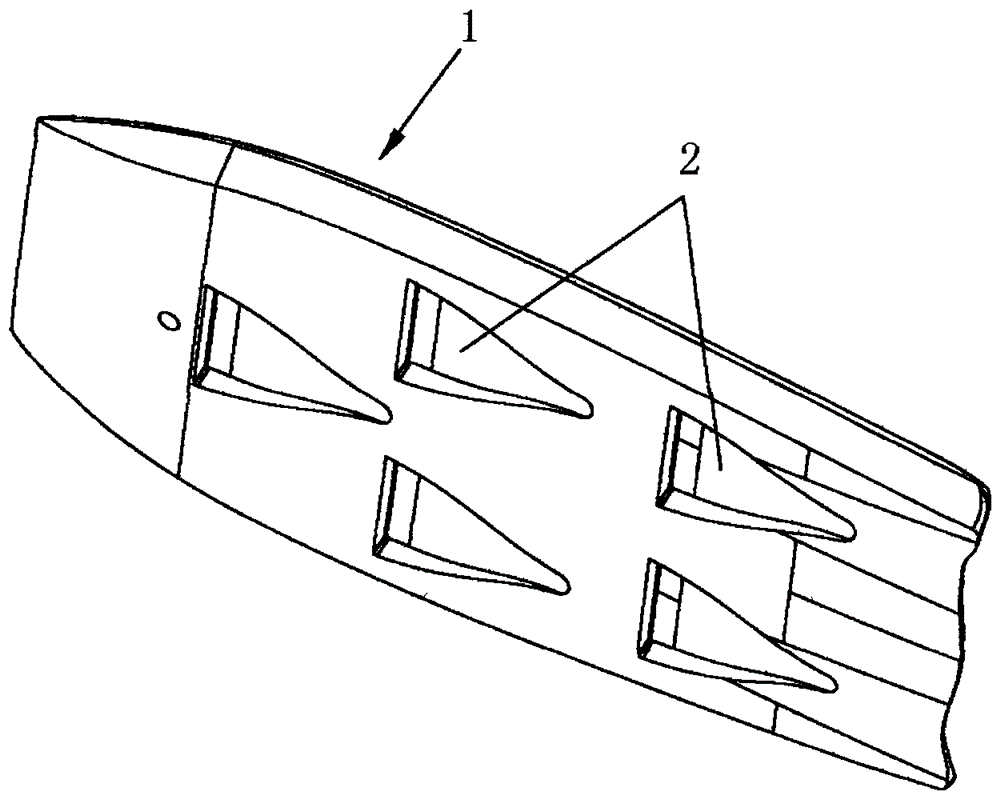

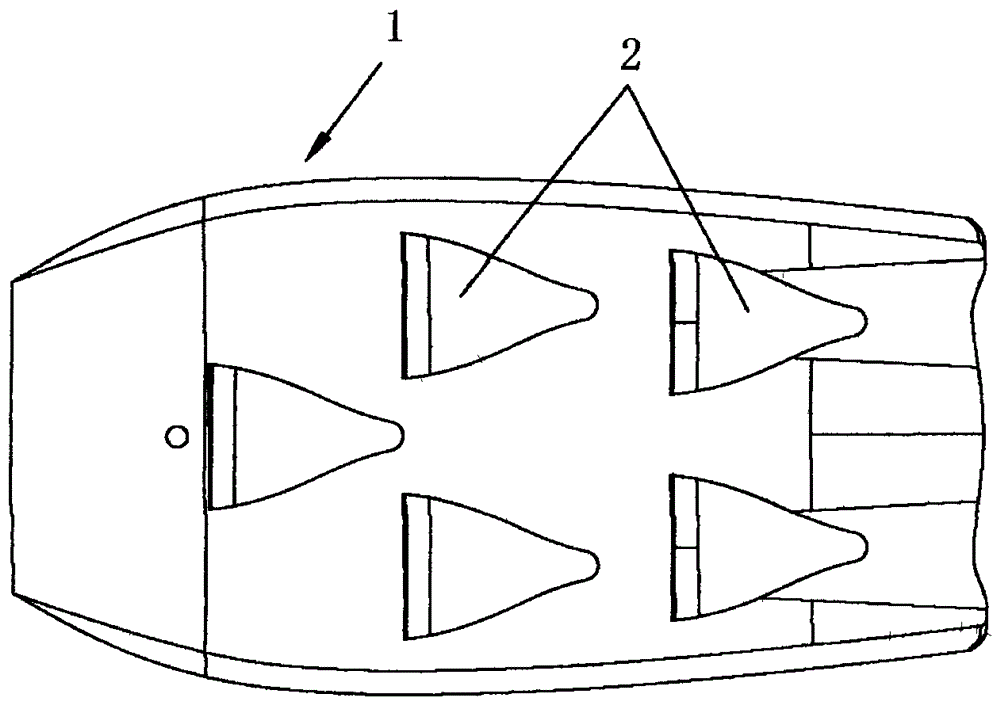

[0030] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~6 As shown, the surfboard 1 of the present invention includes an inner core 11 made of a foam material. The upper and lower surfaces of the inner core 11 are respectively provided with a panel 12 and a bottom plate 13 with materials different from the inner core 11. The inner core 11 passes through The integral molding mode of the mold is combined with the panel 12 and the base plate 13 into one.

[0031] The panel 12 and the bottom plate 13 are respectively bonded to the inner core 11 by hot melt adhesive, so that the combination of the panel 12 , the bottom plate 13 and the inner core 11 is more stable. The bottom plate 13 is molded by injection molding, and the material of the bottom plate 13 is PC, injection molding grade high-density polyethylene or nylon. The panel 12 is molded through a mold, and the material of the panel 12 is polyethylene foam, ethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com