Concrete crack repairing agent with low viscosity and dynamic load structure

A dynamic load, concrete technology, applied in the direction of adhesives, adhesive types, epoxy resin adhesives, etc., can solve the problems of unsafe and reliable, hidden dangers, safety in transportation, etc., and achieve reasonable cost performance, convenient construction, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

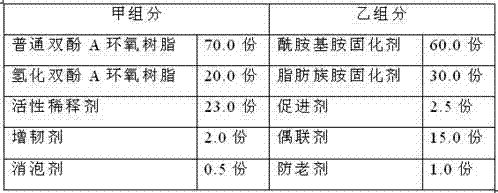

[0041] A low-viscosity dynamic load structural concrete crack repair agent, comprising A component and B component, specifically comprising the following components:

[0042]

[0043] The preparation method of above-mentioned low-viscosity dynamic load structural concrete crack repair agent is as follows:

[0044](1) Preparation of component A: Weigh the raw materials according to the above weight ratio, first mix 70.0 parts of bisphenol A epoxy resin, 20.0 parts of hydrogenated bisphenol A epoxy resin, 23.0 parts of reactive diluent, 2.0 parts of Add the toughening agent into the hydraulic disperser, stir at high speed for 1 hour, finally add 0.5 part of defoamer, stir at medium speed for 0.5 hour, discharge, and pack to obtain the finished product of component A;

[0045] (2) Preparation of component B: Weigh the raw materials according to the above weight ratio, add 60.0 parts of amidoamine curing agent, 30.0 parts of aliphatic amine curing agent, 2.5 parts of accelerato...

Embodiment 2

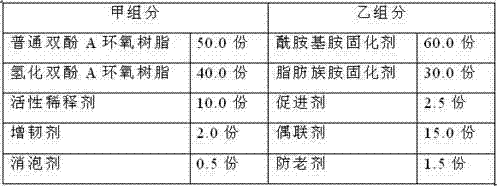

[0049] A low-viscosity dynamic load structural concrete crack repair agent, comprising A component and B component, specifically comprising the following components:

[0050]

[0051] The preparation method of above-mentioned low-viscosity dynamic load structural concrete crack repair agent is as follows:

[0052] (1) Preparation of component A: Weigh the raw materials according to the above weight ratio, first mix 50.0 parts of bisphenol A epoxy resin, 40.0 parts of hydrogenated bisphenol A epoxy resin, 10.0 parts of reactive diluent, 2.0 parts of Add the toughening agent into the hydraulic disperser, stir at high speed for 1 hour, finally add 0.5 part of defoamer, stir at medium speed for 0.5 hour, discharge, and pack to obtain the finished product of component A;

[0053] (2) Preparation of component B: Weigh raw materials according to the weight ratio, add 60.0 parts of amidoamine curing agent, 30.0 parts of aliphatic amine curing agent, 2.5 parts of accelerator, and 15...

Embodiment 3

[0057] A low-viscosity dynamic load structural concrete crack repair agent, comprising A component and B component, specifically comprising the following components:

[0058]

[0059] The preparation method of above-mentioned low-viscosity dynamic load structural concrete crack repair agent is as follows:

[0060] (1) Preparation of component A: Weigh raw materials according to the above weight ratio, first mix 50.0 parts of bisphenol A epoxy resin, 40.0 parts of hydrogenated bisphenol A epoxy resin, 10.0 parts of reactive diluent, 5.0 parts of Add the toughening agent into the hydraulic disperser, stir at high speed for 1 hour, and finally add 1.0 part of defoamer, stir at medium speed for 0.5 hour, discharge, and pack to obtain the finished product of component A;

[0061] (2) Preparation of component B: Weigh the raw materials according to the above weight ratio, add 60.0 parts of amidoamine curing agent, 30.0 parts of aliphatic amine curing agent, 2.5 parts of accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com