Mixed refrigerant containing trifluoroiodomethane

A mixed refrigerant, trifluoroiodomethane technology, applied in the field of mixed refrigerants containing trifluoroiodomethane, can solve the problem of high GWP value, achieve the effect of improving safety and reducing flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take trifluoromethyl iodide, 1,1,1,2-tetrafluoroethane and propane for physical mixing at room temperature to obtain a safe and environmentally friendly mixed refrigerant. In the mixed refrigerant, the concentration of trifluoromethyl iodide is 1wt%, 1,1,1,2-tetrafluoroethane concentration is 40wt%, and propane concentration is 59wt%.

Embodiment 2

[0018] Take trifluoromethyl iodide, 1,1,2,2-tetrafluoroethane and propylene to physically mix at room temperature to obtain a safe and environmentally friendly mixed refrigerant. In this mixed refrigerant, the concentration of trifluoromethyl iodide is 1wt%, 1,1,2,2-tetrafluoroethane concentration is 24wt%, propylene concentration is 75wt%.

Embodiment 3

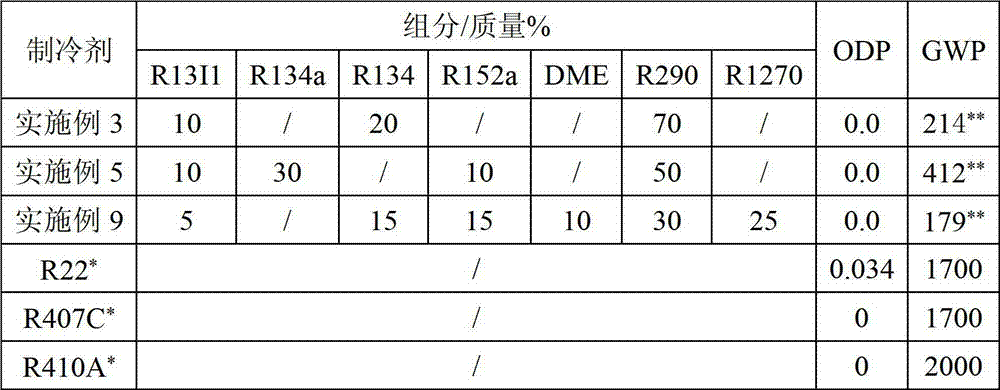

[0020] Take trifluoromethyl iodide, 1,1,2,2-tetrafluoroethane and propane for physical mixing at room temperature to obtain a safe and environmentally friendly mixed refrigerant. In the mixed refrigerant, the concentration of trifluoromethyl iodide is 10wt%, the concentration of 1,1,2,2-tetrafluoroethane is 20wt%, and the concentration of propane is 70wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com