Aluminum alloy cold spraying device and method for magnesium alloy hub

A technology of aluminum alloy and magnesium alloy, which is applied in the field of anti-corrosion spraying on the surface of metal materials, can solve the problems of low bonding strength of substrates, large coating porosity, short service life, etc., and achieve long service life, good corrosion resistance, combined strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

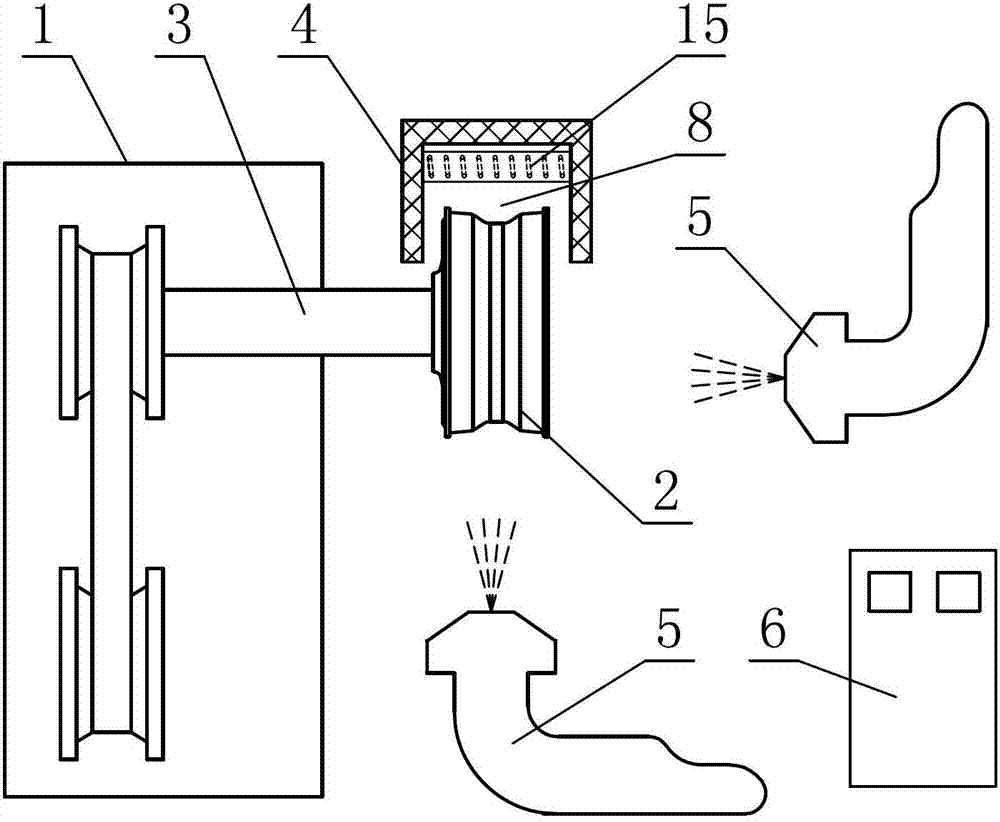

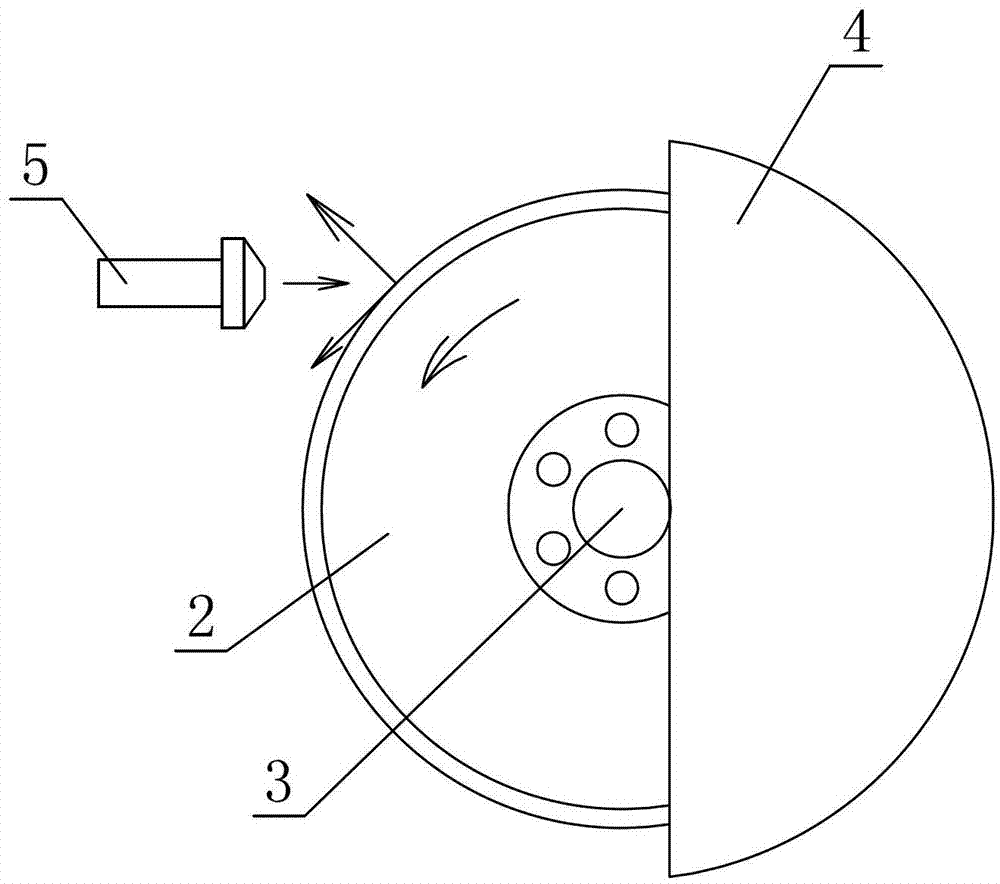

[0034] in such as figure 1 figure 2 In the shown embodiment 1, a device for cold-spraying aluminum alloy on a magnesium alloy hub includes a frame and a hub drive mechanism 1 arranged on the frame, and the hub drive mechanism is provided with a rotating shaft for fixing the hub 2 3. The rotational speed of the rotating shaft is 60 to 120 revolutions per minute. A hub heating device 4 is provided on one side of the rotating shaft. The hub heating device includes a heating chamber 8 that can accommodate part of the hub. The heating chamber is provided with a heating element 15. The heating of the heating chamber The temperature ranges from 70 to 220 degrees Celsius. The frame is also provided with a nozzle 5 for cold spraying aluminum alloy to the wheel hub. The nozzle is arranged on the outer peripheral surface side of the hub and the end face side of the hub respectively. In connection, the device for cold spraying aluminum alloy on the magnesium alloy hub also includes a c...

Embodiment 2

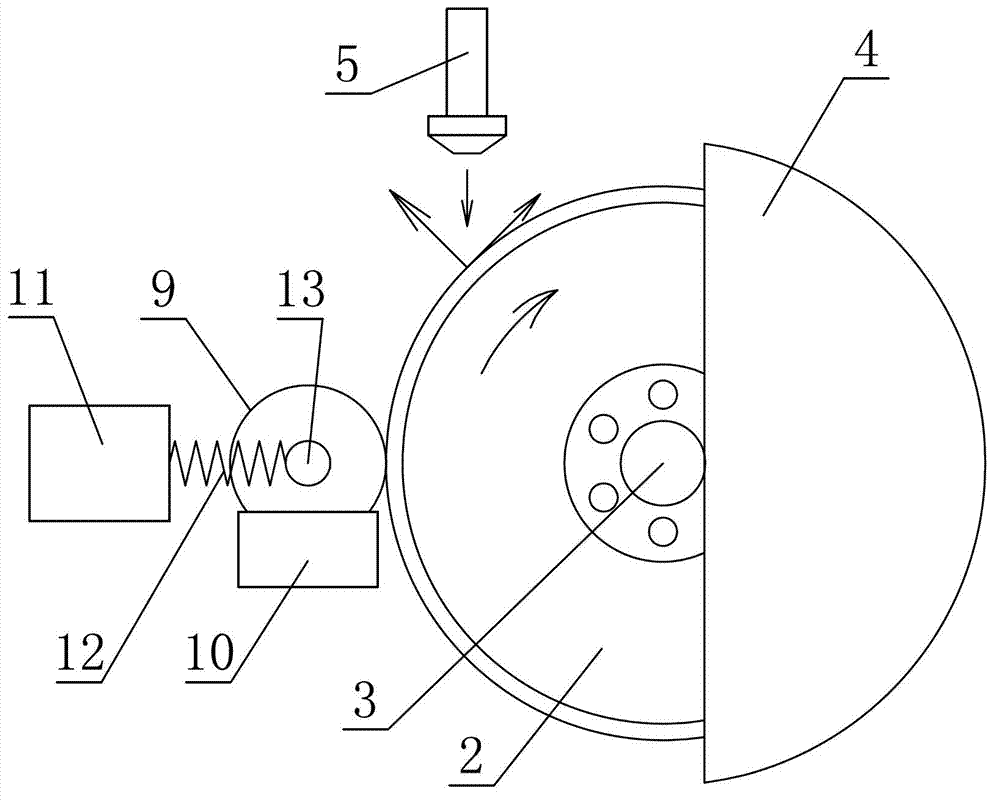

[0044] The frame of embodiment 2 is also provided with a spraying surface pressing device (see image 3 ), the pressing device includes a pressing wheel 9 in rolling contact with the spraying surface, the pressing surface of the pressing wheel is compatible with the spraying surface of the hub, and the average pressure of the pressing surface of the pressing wheel on the hub is 0.3 to 0.8MPa. The spraying surface pressing device includes a pressing wheel heating device 10, the heating temperature of the pressing wheel heating device is consistent with the temperature of the cold sprayed aluminum alloy powder of the nozzle, and the spraying surface pressing device also includes a pressing wheel vibration device 11. The vibration frequency of the pressing wheel vibrating device is 50 to 100 Hz. The pressing wheel vibrating device is connected to the driving shaft 13 of the pressing wheel through a spring 12, and the rest are the same as in Embodiment 1.

[0045] For the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com