Micropump being easy to assemble

A micro-pump and exhaust valve technology, which is used in pump components, variable-capacity pump components, liquid variable-capacity machinery, etc., can solve the problem that the exhaust valve is not installed properly, the construction period is delayed, and the exhaust valve is missing. and other problems, to achieve good promotion potential, reduce working noise, and improve the speed of assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

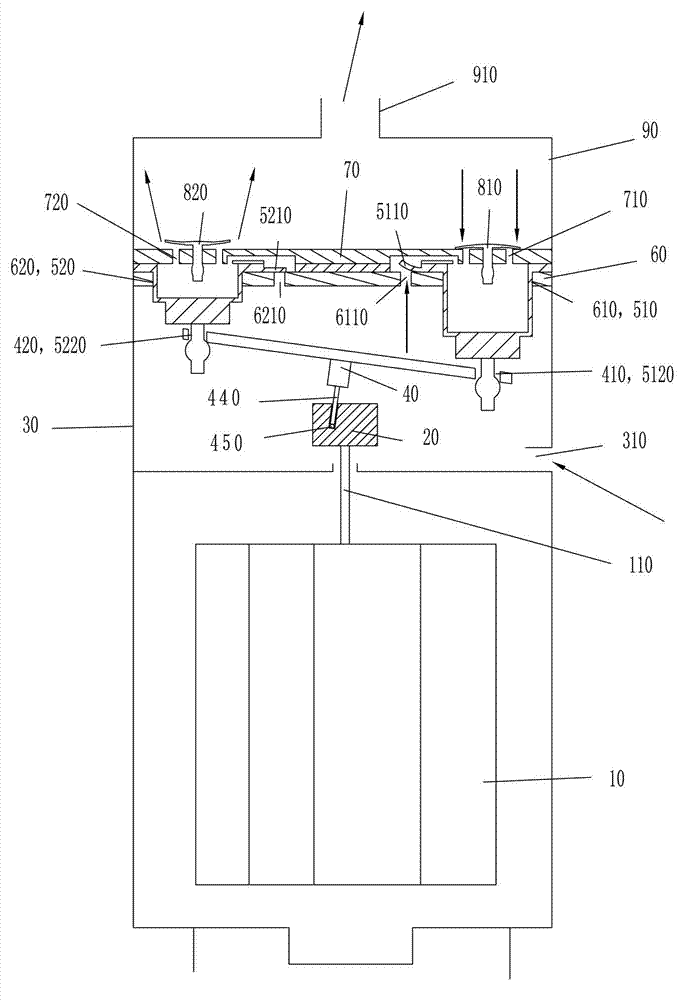

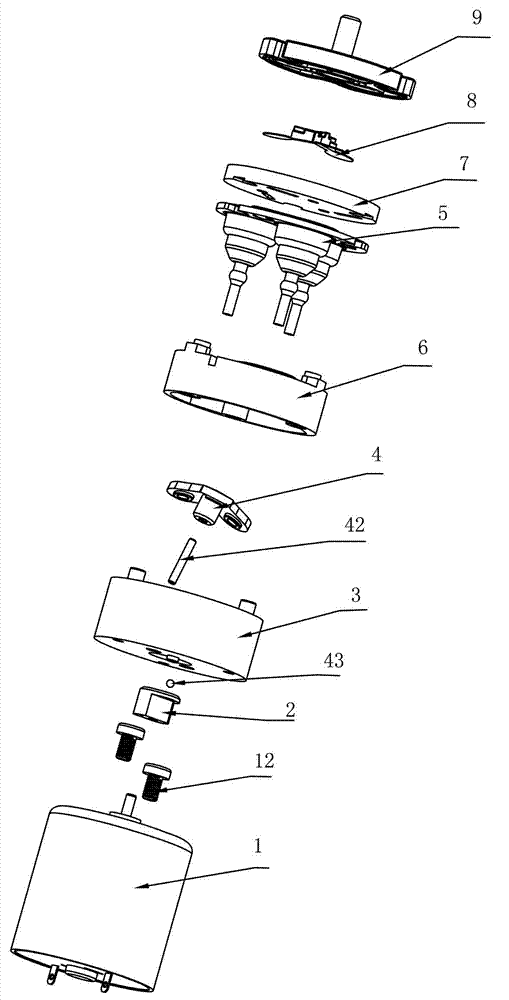

[0048] For the unfolded structure of an embodiment of the micropump that is easy to assemble of the present invention, please refer to figure 2 . The easy-to-assemble micropump has a motor 1, an eccentric wheel 2, a base 3, a steel needle 44, a ball 45, an umbrella-shaped connecting rod 4, a piston body 5, a cylinder plate 6, an air chamber pressure plate 7, an exhaust valve plate group 8 and upper cover9.

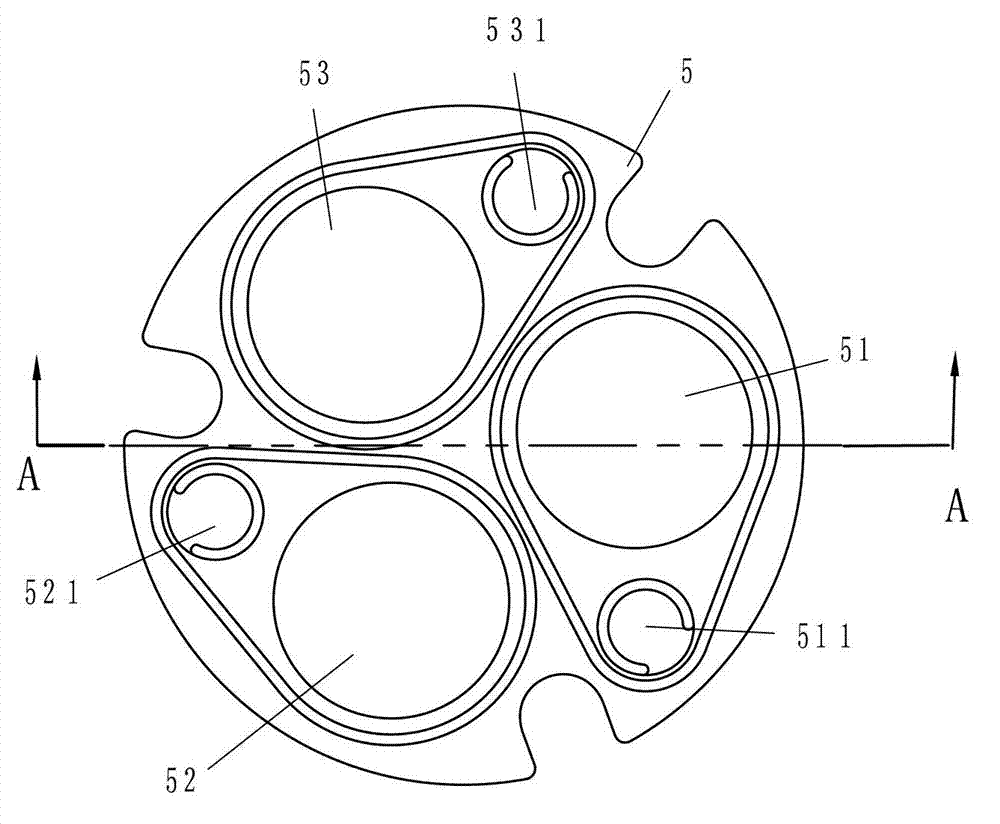

[0049] Please see image 3 with Figure 4 : Piston body 5 made of rubber, three hollow pistons 51, 52, 53 extending downward and three intake valve plates 511, 521, 531 evenly distributed on the flat plate portion of its upper end, three pistons 51, 52 The lower ends of , 53 are respectively provided with engaging portions 512 , 522 , 532 extending downward.

[0050] Please see Figure 5 with Image 6 The three pistons 51, 52, 53 corresponding to the piston body 5 on the cylinder plate 6 are provided with three corresponding cylinder holes 61, 62, 63. The upper sur...

Embodiment 2

[0060] Another embodiment of the micropump that is easy to assemble of the present invention has motor 1, eccentric wheel 2, base 3, steel needle 44, ball 45, umbrella-shaped connecting rod 4, piston body 5 and cylinder plate 6 as previous embodiment, for Their structures and connections will not be described in detail. But the structure and connection relationship of the air chamber pressing plate 7', the exhaust valve sheet group 8' and the loam cake 9' in the present embodiment are different from the previous embodiment.

[0061] Please see Figure 16 Three pistons 51, 52, 53 corresponding to the piston body 5 on the air chamber pressing plate 7 ' are provided with three corresponding exhaust holes 71 ', 72 ', 73 '. In the middle of the upper end surface of the air chamber pressure plate 7', corresponding to the three exhaust holes 71', 72', 73', a triangular central groove 701' is arranged. The air holes 71', 72', 73' are respectively provided with circular grooves 705',...

Embodiment 3

[0069]Another embodiment of the micropump that is easy to assemble of the present invention has motor 1, eccentric wheel 2, base 3, steel needle 44, ball 45, umbrella-shaped connecting rod 4, piston body 5 and cylinder plate 6 as first embodiment, Their structures and connection relationships will not be described in detail. However, the structure and connection relationship of the air chamber pressing plate 7 ″, the exhaust valve sheet group 8 ″ and the upper cover 9 ″ in this embodiment are different from those in the first embodiment.

[0070] Please see Figure 20 : Three pistons 51, 52, 53 corresponding to the piston body 5 on the air chamber pressure plate 7" are provided with three corresponding exhaust holes 71", 72", 73". Corresponding to the three exhaust holes 71", 72", and 73" in the middle of the upper end surface of the air chamber pressure plate 7, a triangular central groove 701" with a side line concave inward is provided, and on the three vertices of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com