Full-fresh-air air handling unit capable of overcooling and overheating synchronously

An air handling unit and superheating technology, which is applied in the field of building environment and equipment engineering, can solve the problems of not considering the control of refrigerant superheat, affecting the stability and safety of the refrigeration system, and reducing the performance of fresh air air handling units. , to achieve the effect of guaranteeing performance, enhancing stability and reliability, and improving refrigeration energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

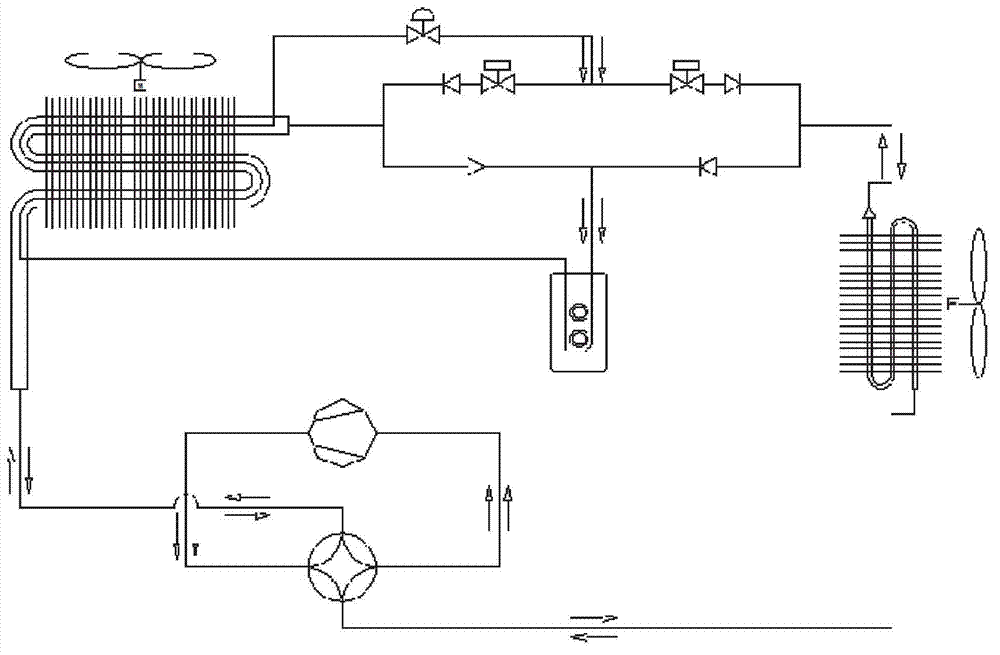

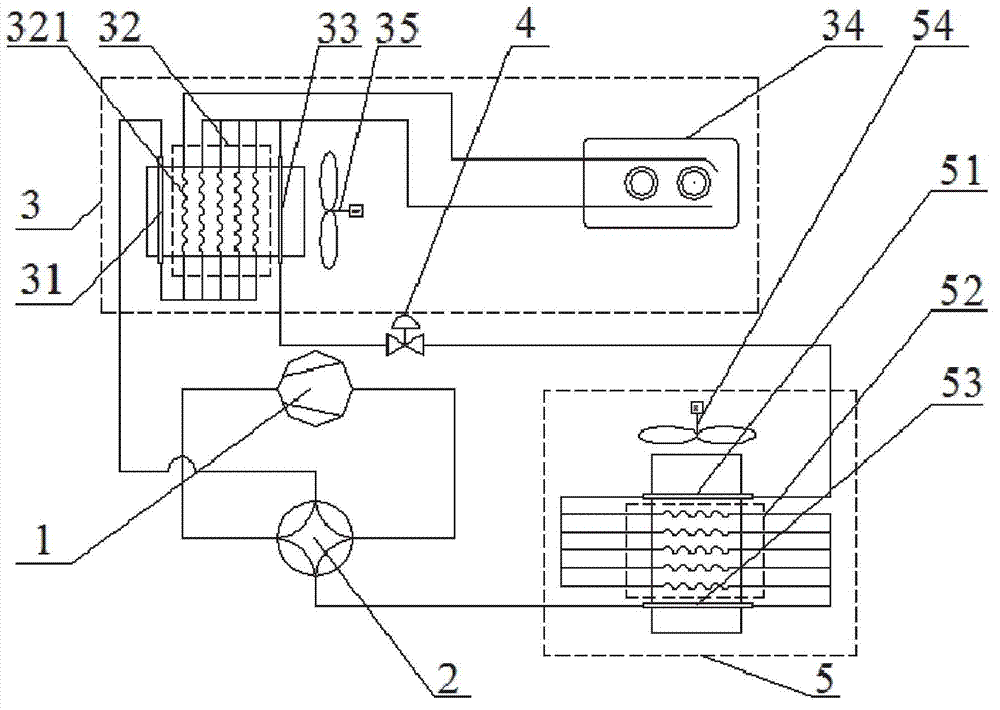

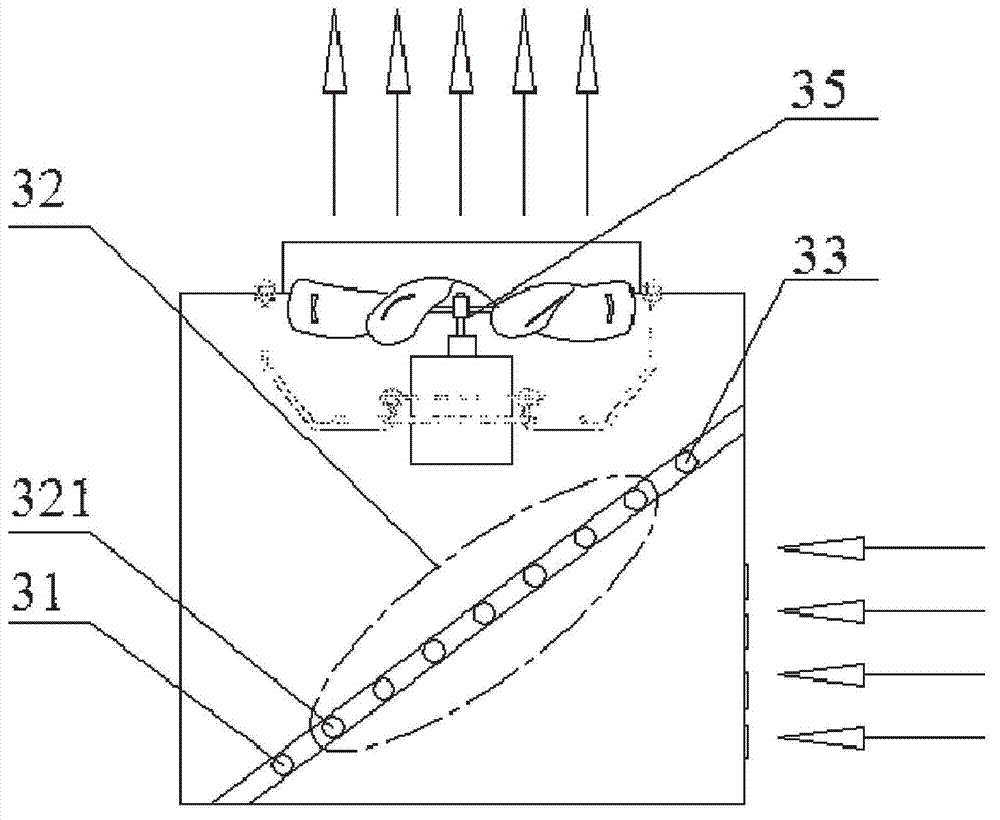

[0040] Embodiment 1 of the present invention is the first type of outdoor processing unit heat exchanger 3 and indoor air supply unit heat exchanger 5 . Both the fans of the heat exchanger 3 of the outdoor processing unit and the heat exchanger 5 of the indoor air supply unit are upward air outlets, and the distribution vector diagrams of their wind speeds conform to the upper triangle. When the structure of the heat exchanger is determined, this specific air supply mode has a one-to-one correspondence with the upper triangle distribution vector diagram of the wind speed. It can be seen from the upper triangular wind speed distribution vector diagram that the wind speed at the upper part of the heat exchanger is high, so when the external air sweeps across the upper branch of the heat exchanger, the effect of forced heat exchange with the refrigerant in the tube is good. The uppermost branch of the heat exchanger 5 of the device 3 and the indoor air supply unit is set as an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com