Drying equipment applying sealed negative pressure air supply system

A technology of air supply system and drying equipment, applied in drying chamber/container, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of increasing moisture content of drying materials, increasing partial pressure of water vapor, decreasing drying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

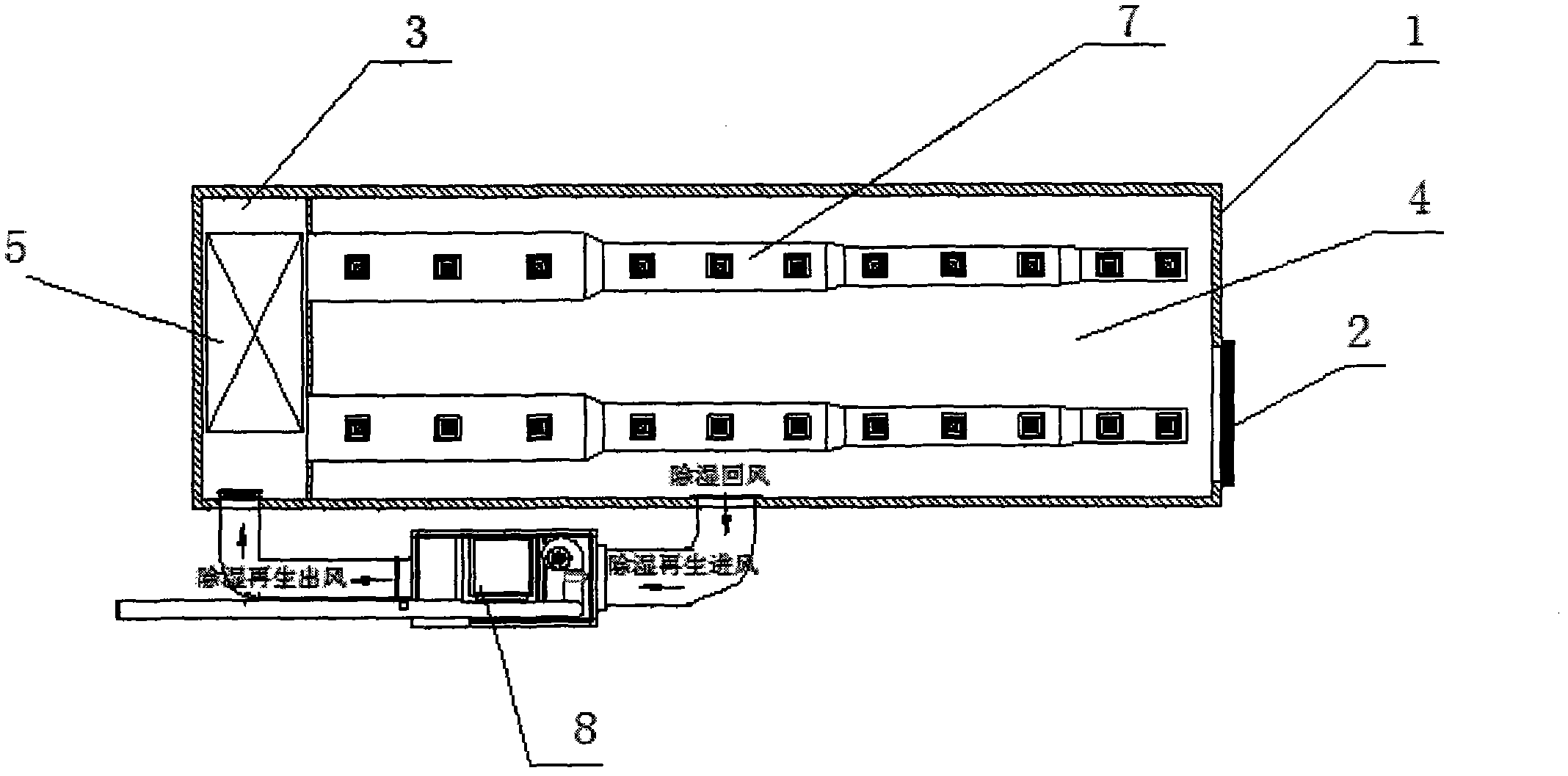

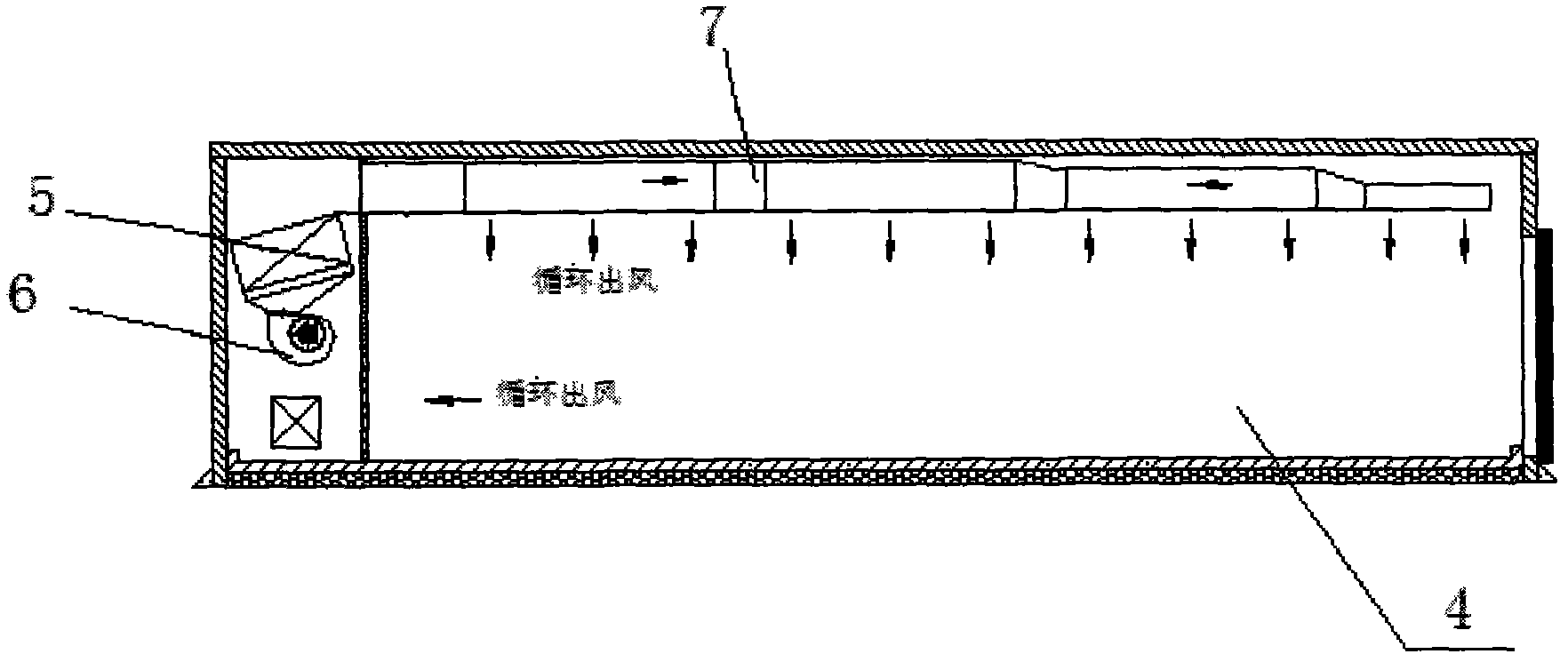

[0011] Such as figure 1 and figure 2 As shown, a drying device using a sealed negative pressure air supply system described in this embodiment includes an airtight storage body 1, and is characterized in that a storage door 2 is arranged on the airtight storage body 1 , the airtight storage body 1 is composed of a heat treatment area 3 and a drying area 4, a heat exchanger 5 is arranged in the heat treatment area 3, a fan 6 is arranged at the bottom of the heat exchanger 5, and a fan 6 is arranged in the drying area 4 A pipeline 7 connecting the heat treatment area 3 is provided. In practical applications, the fan 6 relies on the input mechanical energy to increase the gas pressure and discharge the gas to the heat exchanger 5. The cooling gas passing through the heat exchanger 5 passes through the gas pressure driven by the air pressure. Circulate back to the drying area 4 through the pipeline 7; a runner dehumidification device 8 is arranged outside the airtight warehouse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com