Cooling and drying integrated machine

An all-in-one, cold-drying technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unreachable users, high air dew point temperature, low heat exchange efficiency, etc. The effect of low temperature and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

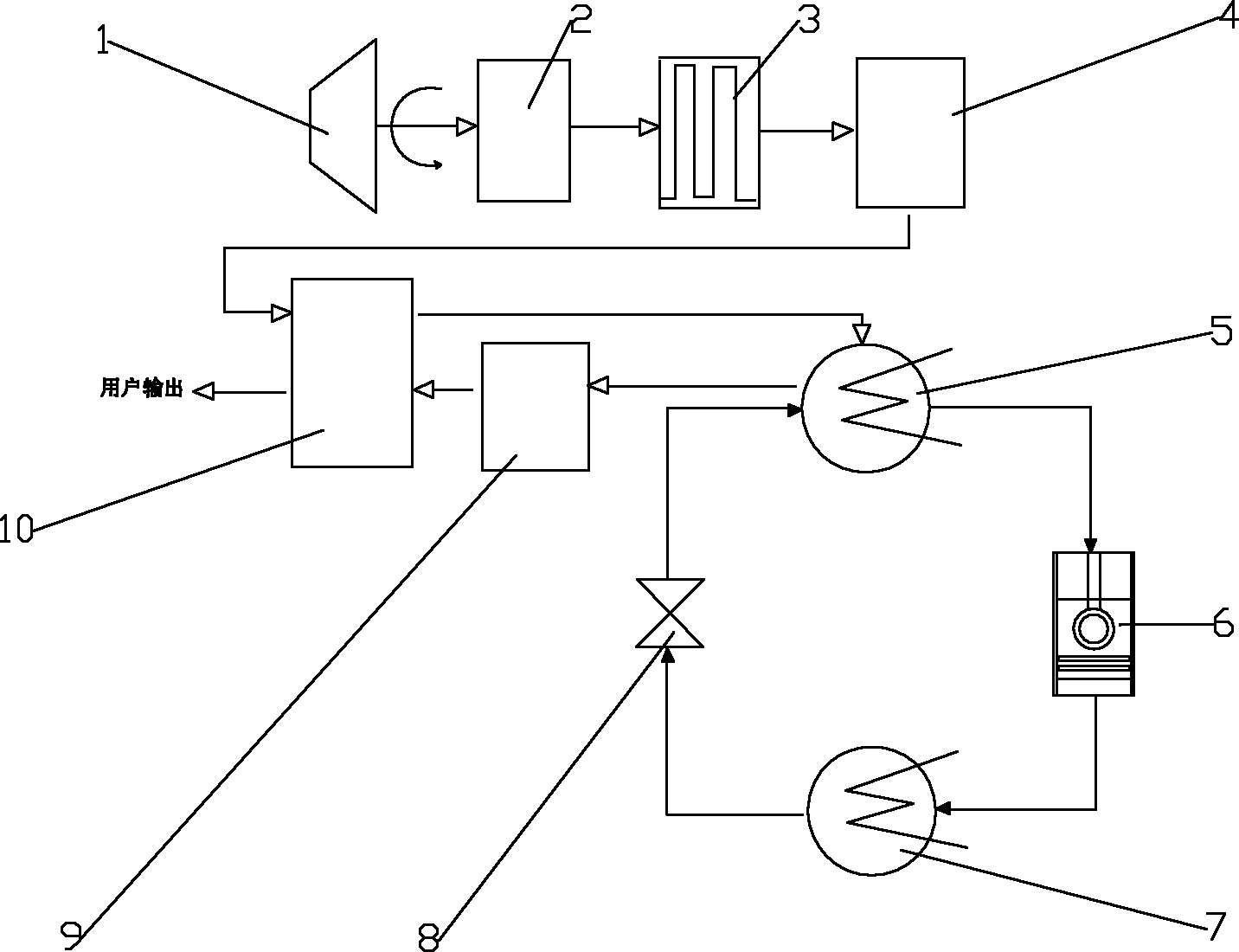

[0036] Such as figure 1 As shown, the integrated refrigeration and drying machine of the present invention includes a scroll compressor 1, a filter 2, a radiator 3, a gas cylinder 4, a shell-and-tube precooler 10, a heat pipe evaporator 5, a gas-liquid The separator 9 and the air conditioning system. The gas outlet of the gas-liquid separator 9 is connected to the cold fluid inlet of the shell and tube precooler 10. The air conditioning system consists of the heat pipe evaporator 5 and the piston compressor 6, The condenser 7 and the expansion valve 8 are connected in sequence.

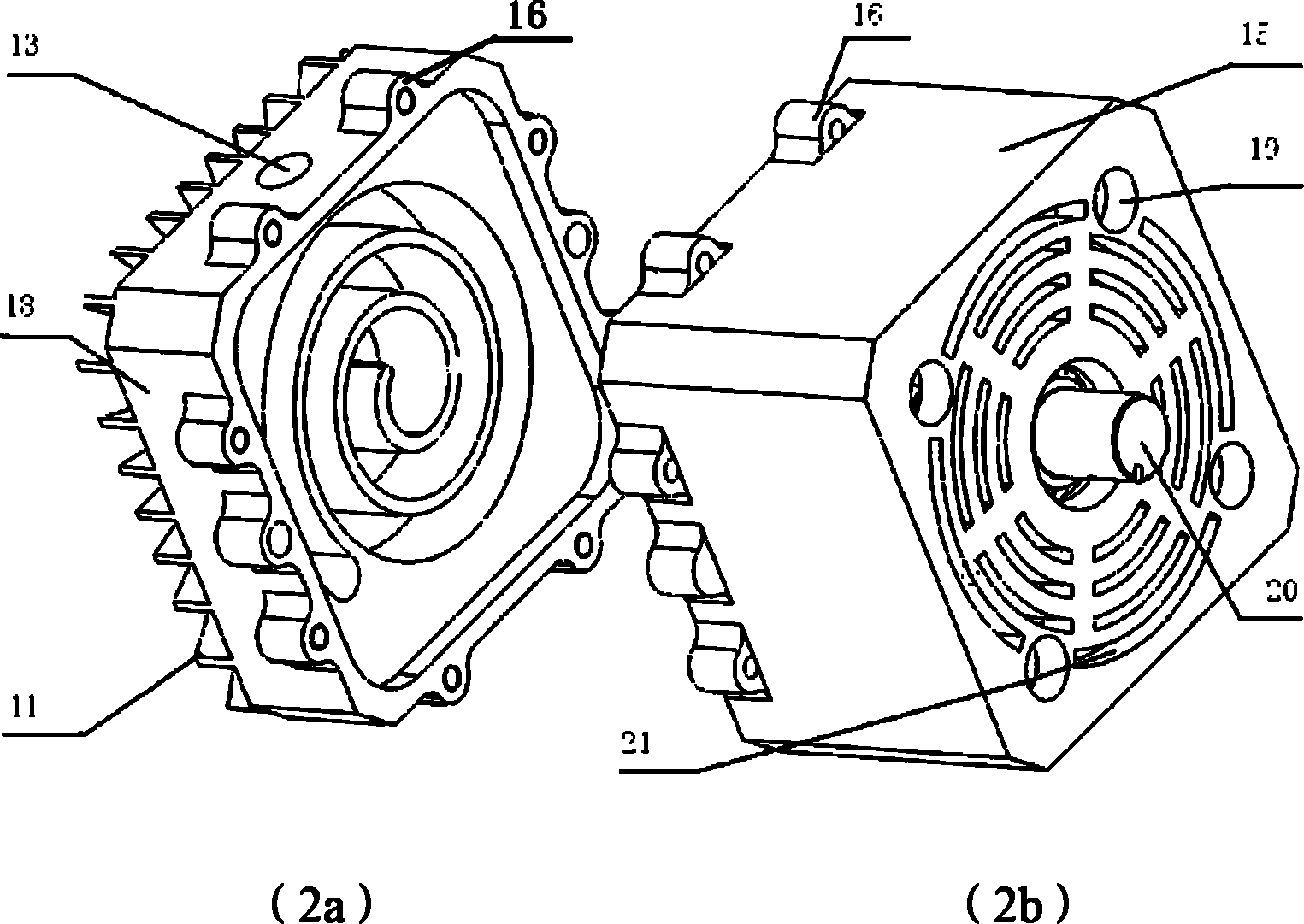

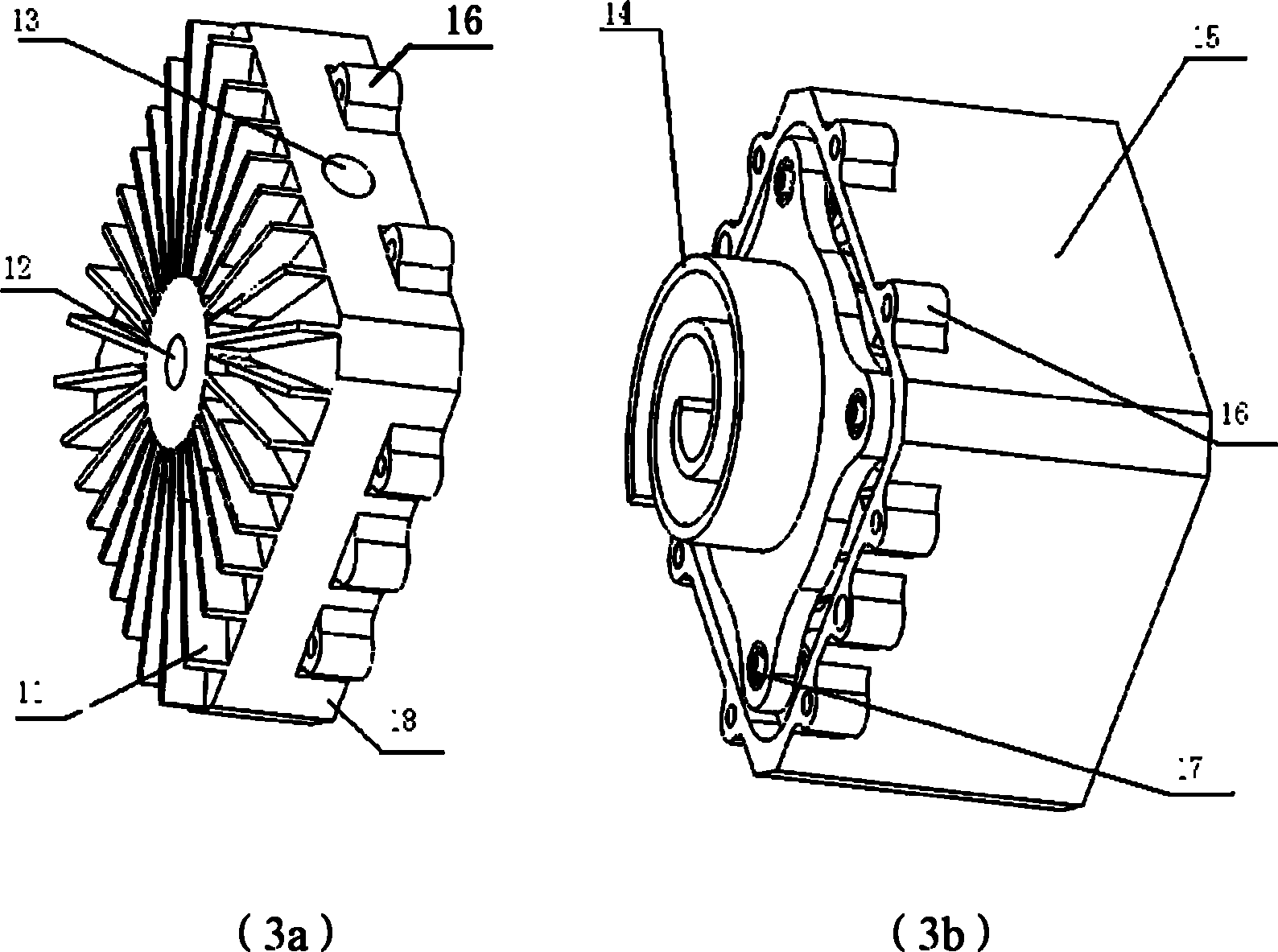

[0037] Such as figure 2 , image 3 As shown, the scroll compressor 1 includes a static plate 18, a movable plate 14, a bracket 15, an eccentric small shaft 17 and an eccentric main shaft 20. Where as figure 2 a. image 3 As shown in a, the top surface of the static plate 18 is provided with radiating fins 11, the center of the radiating fin 11 is provided with an air outlet 12, and the side of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com