Method for solving problem of acid returning permeation of metal cracks subjected to corrosion of corrosives

A corrosive and crack technology, applied in the preparation of test samples, etc., can solve the problems of retention, inconvenient material detection and analysis, and contamination of the surface of the sample.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1): The sampling and processing methods of metallographic samples are based on GB13298-1991, and the samples with a working area of 10×10mm are cut by water-cooled grinding wheel cutting method, and the samples are inlaid with resin by hot mounting method. Manually polish and polish with 180#, 240#, 600# and 1200# sandpaper respectively;

[0033] 2): First add 3g Na 2 CO 3 Place in a beaker, then add 100mL of distilled water, and stir well. Immediately immerse the metallographic sample that has not been dried after corrosion into this special reagent, and vibrate the sample with an ultrasonic cleaner for 10 minutes (CBL C9860A type ultrasonic cleaner tank size: 300×240×150mm, ultrasonic frequency 40KHz, capacity: 10L, the timing is 10min);

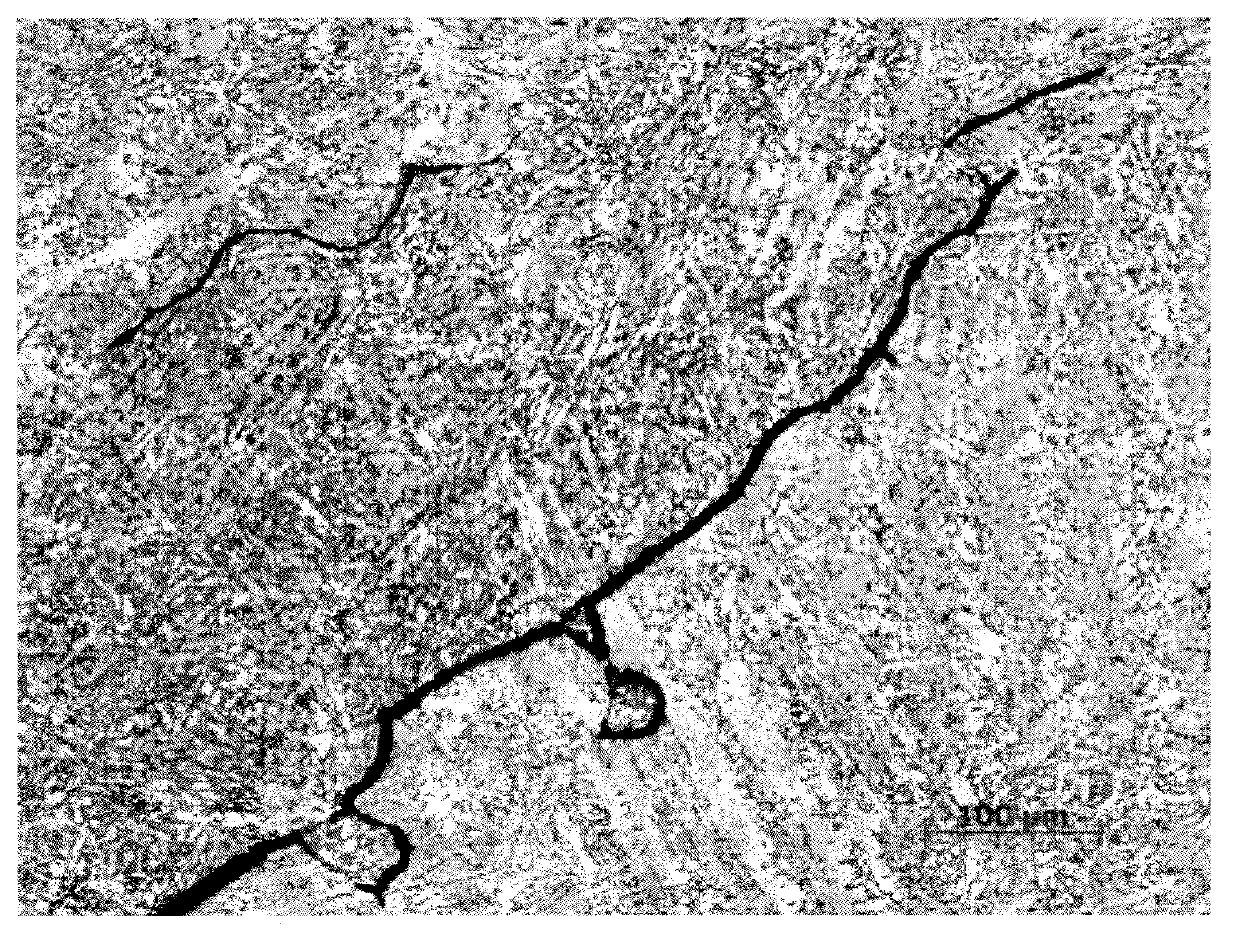

[0034] 3): Take out the metallographic sample and rinse it with clear water, then dry it with a hair dryer after cleaning with alcohol, observe the metallographic structure of the sample with a metallographic microscope, and ob...

Embodiment 2

[0036] 1): The sampling and processing methods of metallographic samples are based on GB13298-1991, and the samples with a working area of 10×10mm are cut by water-cooled grinding wheel cutting method, and the samples are inlaid with resin by hot mounting method. Manually polish and polish with 180#, 240#, 600# and 1200# sandpaper respectively;

[0037] 2): first add 10g NaHCO 3 Place in a beaker, then add 100mL of distilled water, and stir well. Immediately immerse the metallographic sample that has not been dried after corrosion into this special reagent, and vibrate the sample for 3 minutes with an ultrasonic cleaner (CBL C9860A type ultrasonic cleaner tank size: 300×240×150mm, ultrasonic frequency 40KHz, capacity: 10L, the timing is 3min);

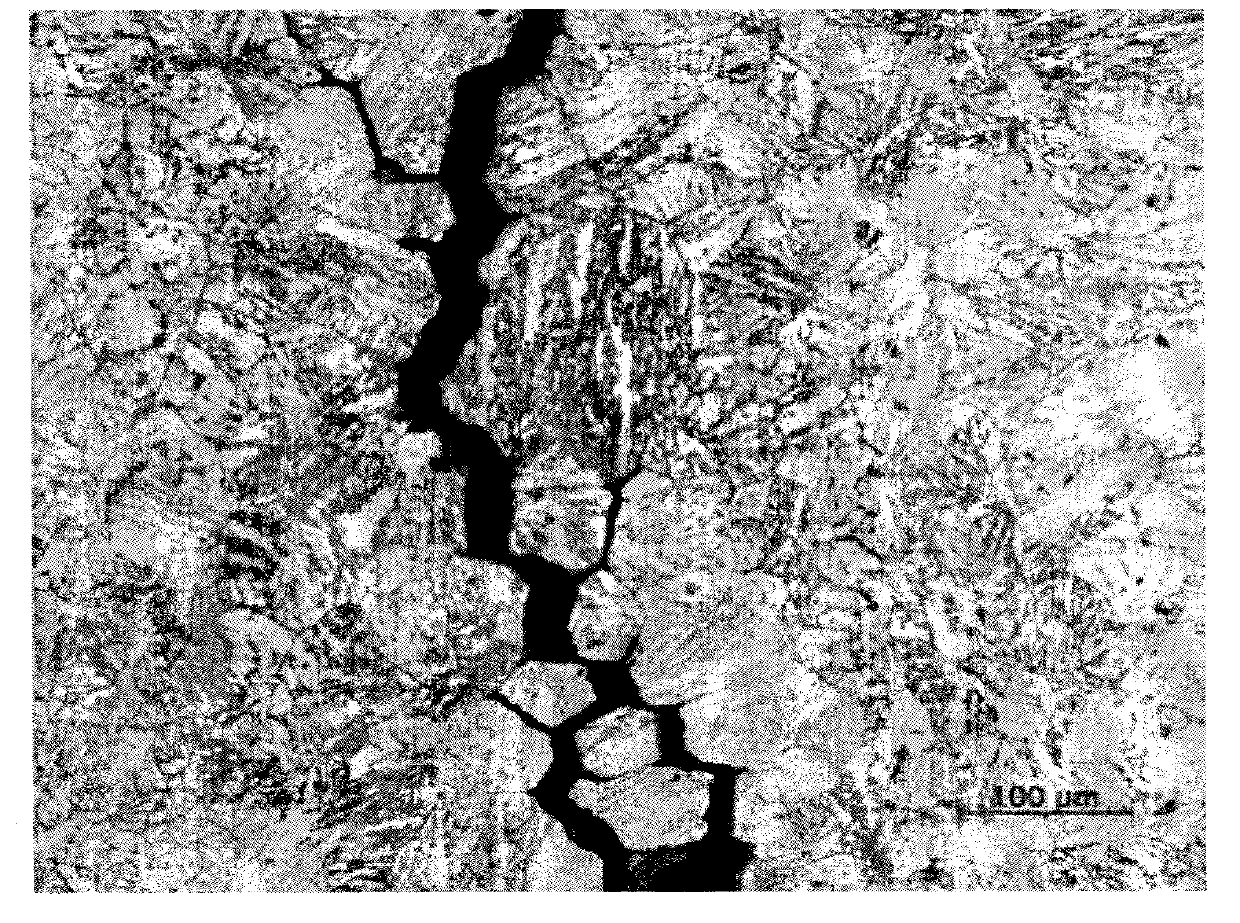

[0038] 3): Take out the metallographic sample and rinse it with clear water, then dry it with a hair dryer after cleaning with alcohol, observe the metallographic structure of the sample with a metallographic microscope, and obtain...

Embodiment 3

[0040] 1): The sampling and processing methods of metallographic samples are based on GB13298-1991, and the samples with a working area of 10×10mm are cut by water-cooled grinding wheel cutting method, and the samples are inlaid with resin by hot mounting method. Manually polish and polish with 180#, 240#, 600# and 1200# sandpaper respectively;

[0041] 2): First add 20g Na 2 CO 3 Place in a beaker, then add 100mL of distilled water, and stir well. Immediately immerse the metallographic sample that has not been dried after corrosion into this special reagent, and vibrate the sample with an ultrasonic cleaner for 2 minutes (CBL C9860A ultrasonic cleaner tank size: 300×240×150mm, ultrasonic frequency 40KHz, capacity: 10L, the timing is 2min);

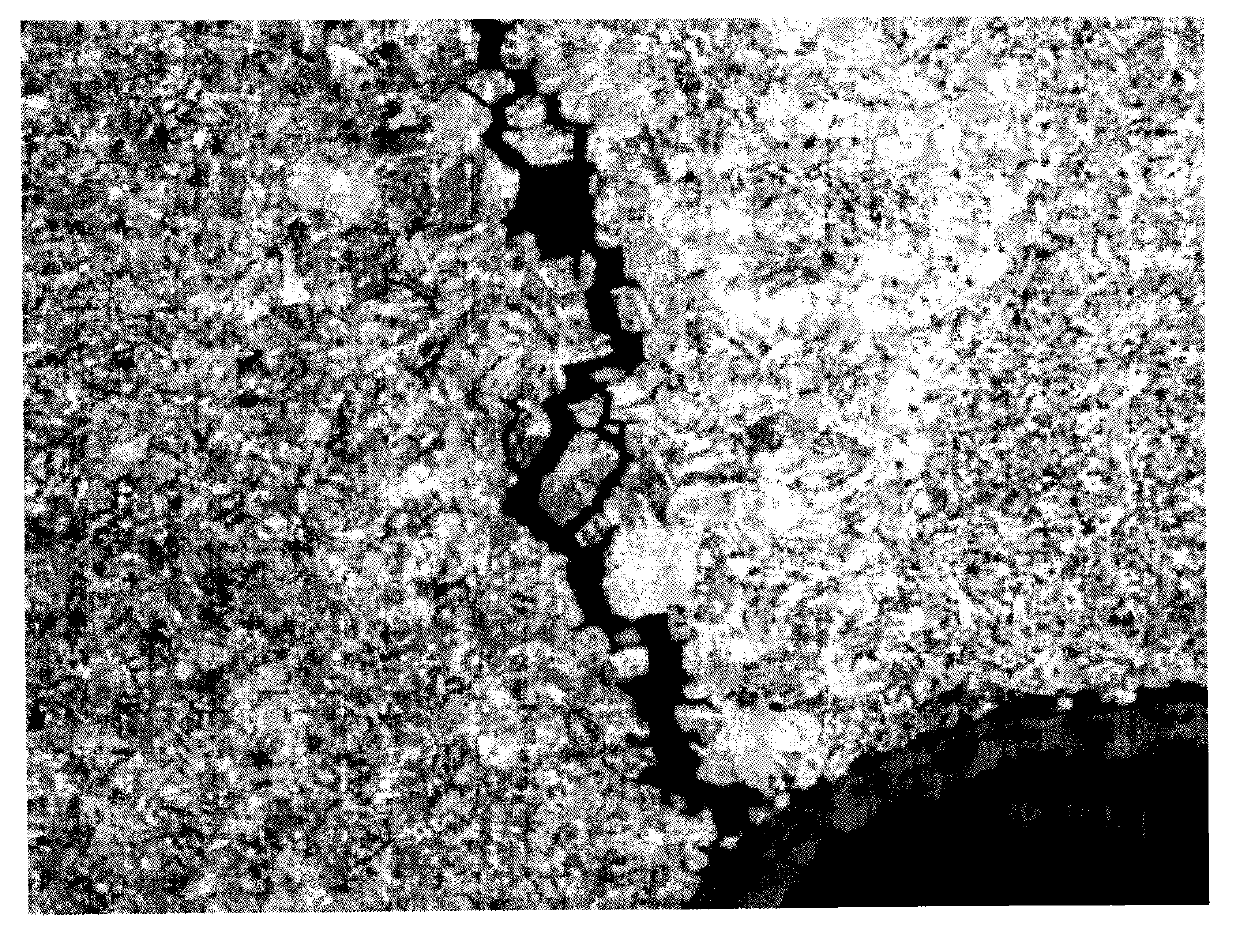

[0042] 3): Take out the metallographic sample and rinse it with clear water, then dry it with a hair dryer after cleaning with alcohol, observe the metallographic structure of the sample with a metallographic microscope, and obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com