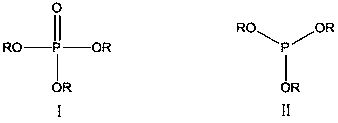

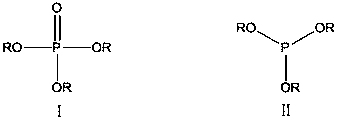

Method for removing Lewis acid ionic liquid catalyst in phosphate flame retardant product

A technology of liquid catalyst and phosphate ester, which is applied in chemical instruments and methods, phosphorus organic compounds, organic chemistry, etc. It can solve the problems of large acid value, cumbersome process, and unreported simplified methods, so as to ensure quality and solve acid reflux problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Phosphorus oxychloride and propylene oxide were used as raw materials, and tris(β-chloropropyl)phosphate (TCPP) was prepared by esterification reaction under the action of acidic ionic liquid catalyst. Add 15.4g of phosphorus oxychloride and 0.66g of aluminum trichloride into a four-necked flask equipped with a thermometer, reflux condenser, and electric stirrer, heat to 45-55°C, add 18.4g of propylene oxide dropwise, and keep the reaction temperature At 60-70°C. After the dropwise addition, continue the heat preservation reaction for 2 h, and distill off the unreacted substances under reduced pressure to obtain the crude product of TCPP.

[0028] Add dropwise 0.15g (equivalent to 0.45% of the total mass of TCPP product) water 60-70 in the reaction device o Stir at C for 0.5-1h, then add 0.068g Ca(OH) 2 (Equivalent to 0.2% of the total mass of TCPP products) Stir for 1-2 hours, blow nitrogen to remove water, and filter while hot to obtain low-acid value and low-moistu...

Embodiment 2

[0032] Phosphorus oxychloride and ethylene oxide are used as raw materials, and tris(β-chloroethyl)phosphate (TCEP) is prepared by esterification under the action of an acidic ionic liquid catalyst. Add 15.4g of phosphorus oxychloride and 0.57g of titanium tetrachloride into a four-necked flask equipped with a thermometer, reflux condenser, and electric stirrer, heat to 40-50°C, add 14.2g of ethylene oxide dropwise, and keep the reaction The temperature is 55-65°C. After the dropwise addition, the reaction was continued for 3 h, and the unreacted substances were removed by distillation under reduced pressure to obtain the crude product of TCEP.

[0033] Add 0.133g (equivalent to 0.45% of the total mass of TCEP product) water 55-65 in the reaction device o Stir at C for 0.5-1h, then add 0.0592g Ca(OH) 2 (Equivalent to 0.2% of the total mass of TCEP products) Stir for 1-2 hours, blow nitrogen to remove water, and filter while hot to obtain TCEP products with low acid value and...

Embodiment 3

[0037] Phosphorus oxychloride and epichlorohydrin are used as raw materials to obtain tris(2,3-dichloropropyl)phosphate (TDCPP) through esterification under the action of acidic ionic liquid catalyst. Add 15.4g of phosphorus oxychloride and 0.86g of aluminum trichloride into a four-necked flask equipped with a thermometer, reflux condenser, and electric stirrer, heat to 50-60°C, add 29.8g of epichlorohydrin dropwise, and keep the reaction The temperature was 70-80°C. After the dropwise addition, the reaction was continued for 3.5 hours, and the unreacted substances were distilled off under reduced pressure to obtain the crude product of TDCPP.

[0038] Add 0.120g (equivalent to 0.45% of the total mass of TDCPP product) water 70-80% in the reaction device o Stir at C for 0.5-1h, then add 0.0888g Ca(OH) 2 (Equivalent to 0.2% of the total mass of the TDCPP product) Stir for 1-2 hours, blow nitrogen to remove water, and filter while hot to obtain a low-acid value and low-moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com