Manganese electrolytic cell equipment

An electrolytic cell and manganese electrolysis technology, applied in the field of electrolytic cell, can solve problems such as unsatisfactory sealing effect, influence on the pH value of electrolyte, increase power consumption, etc., reduce production cost and maintenance cost, simple structure, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

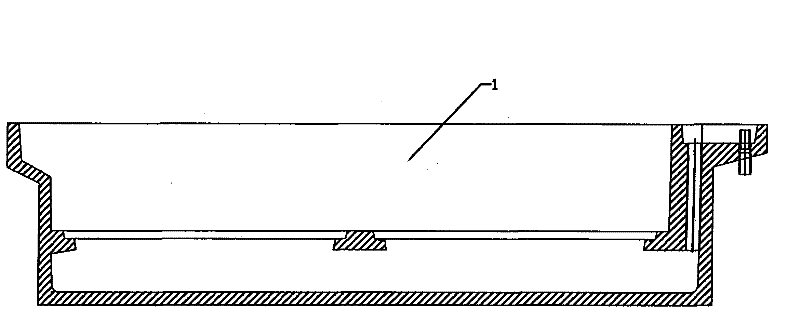

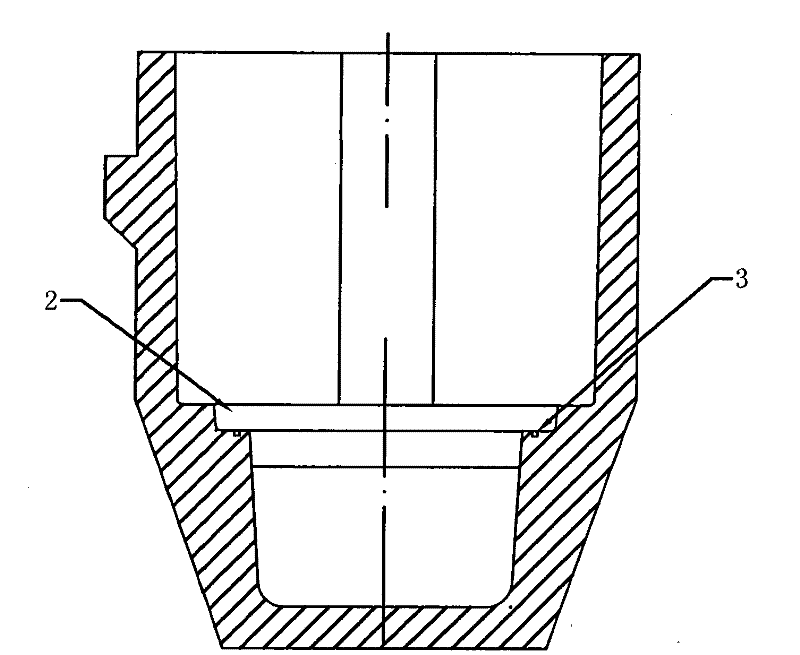

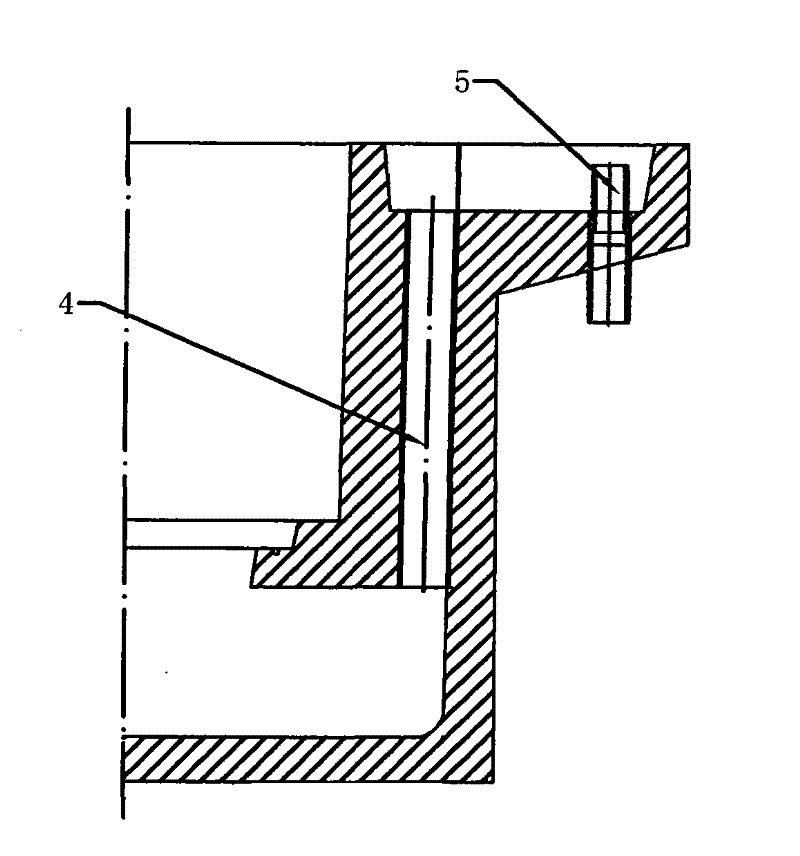

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 and figure 2 As shown, the manganese electrolytic cell of the present invention at least includes a fixed frame, an electrolytic cell body, an anode plate, a negative plate, a false bottom, a bottom liquid conduit, an overflow port, etc., and the electrolytic cell body 1 is integrally made of resin concrete Casting makes the electrolytic cell body 1 obtain higher strength, solves the leakage problem of the electrolytic cell body 1, greatly improves its corrosion resistance and has a long service life; the false bottom 2 is used Resin concrete is integrally cast at one time, which makes the overall structure of the electrolytic cell body 1 firm and has strong sealing performance. The wired sealing groove 3 is cast on the false bottom 2. Since the sealing effect of the line is better than that of the surface, it can well solve the problem of acid return.

[0011] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com