Optimization method of control parameters of servo system of numerical controlled machine tool

A technology for controlling parameters and servo systems, applied in the field of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

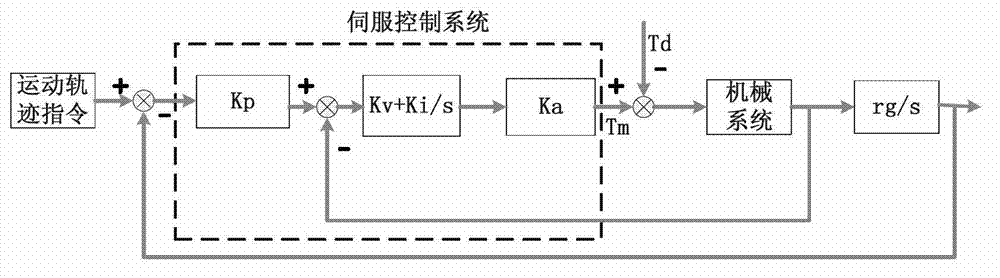

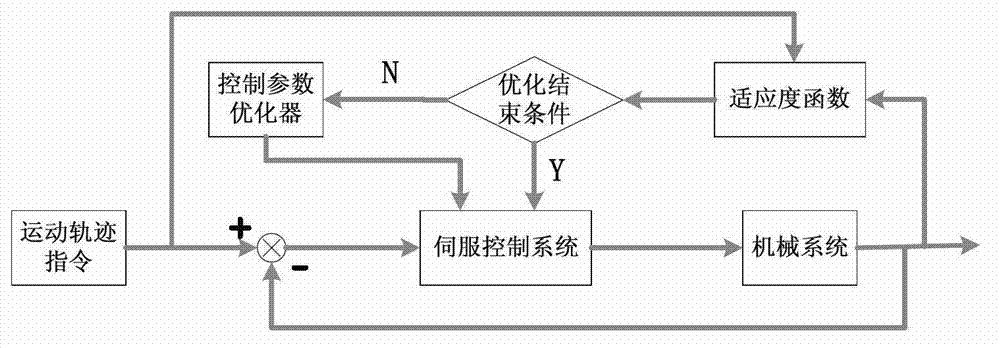

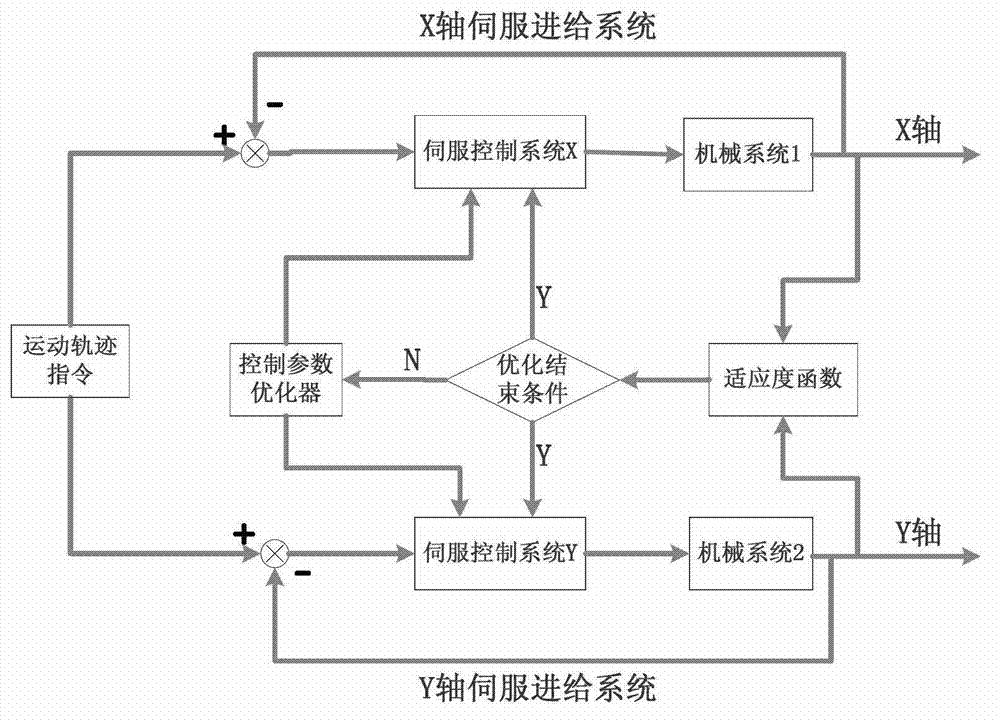

[0068] The numerical control machine tool servo control system control parameter optimization method of the present invention comprises the following steps:

[0069] 1) First, the user determines the three-loop control parameters of the CNC machine tool servo system to be optimized, the number of samples of parameters in each optimization process, the number of linkage axes, the range of control parameters, the maximum number of optimization times, the optimization end criteria, global search capabilities and local searches Capability quantification index (value between 0-1). The boundary value of the selected range of control parameters of the CNC machine tool servo system is the critical control parameter value that causes the unstable working state of the machine tool. The optimization end criterion is the performance index that needs to be achieved by the dynamic characteristics of the CNC machine tool servo system, that is, the fitness function. The single-axis control o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com