Method for realizing low-temperature ohm annealing of P type SiC materials

A high-temperature rapid annealing and alloying technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., to achieve the effect of avoiding quality, small surface roughness, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

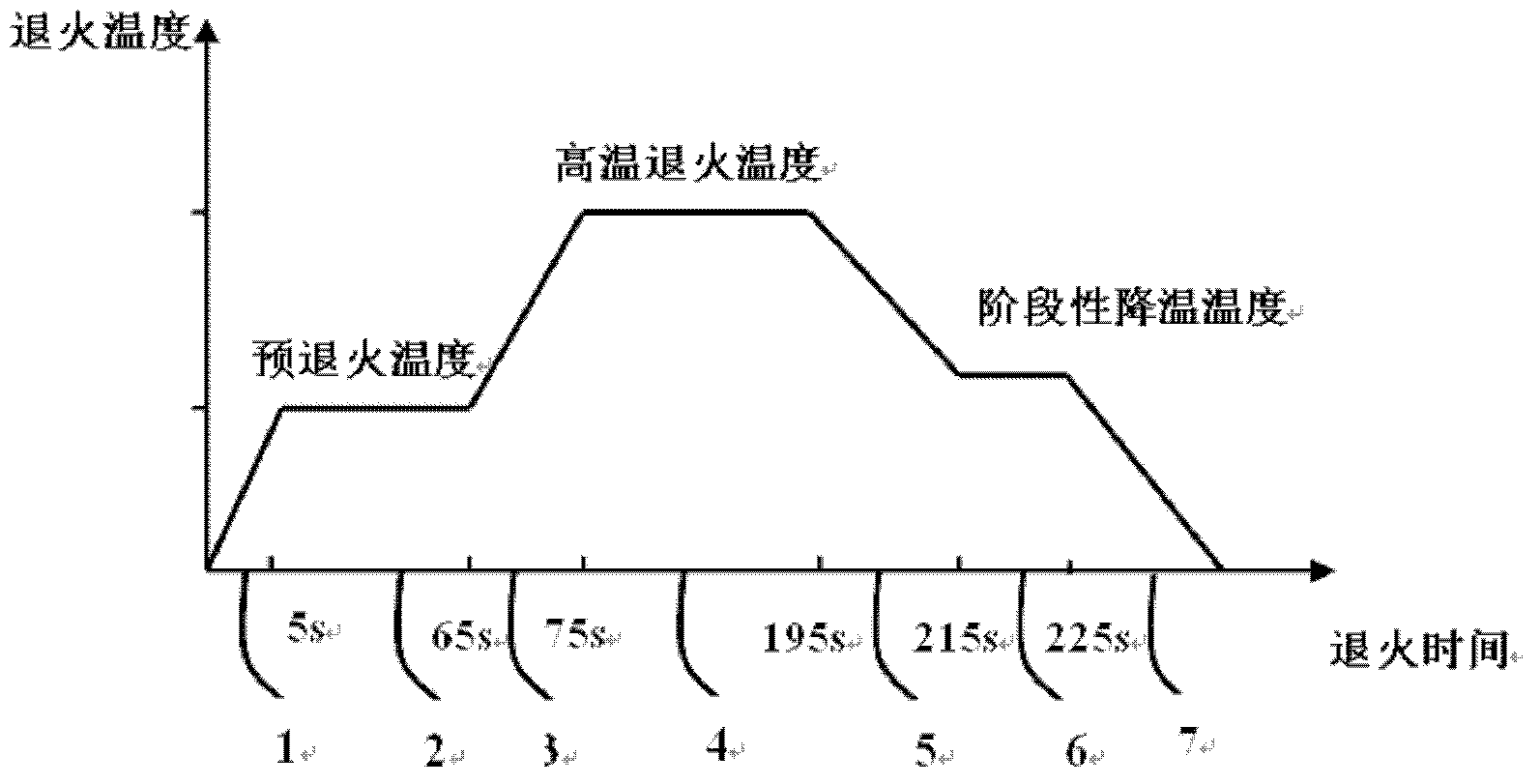

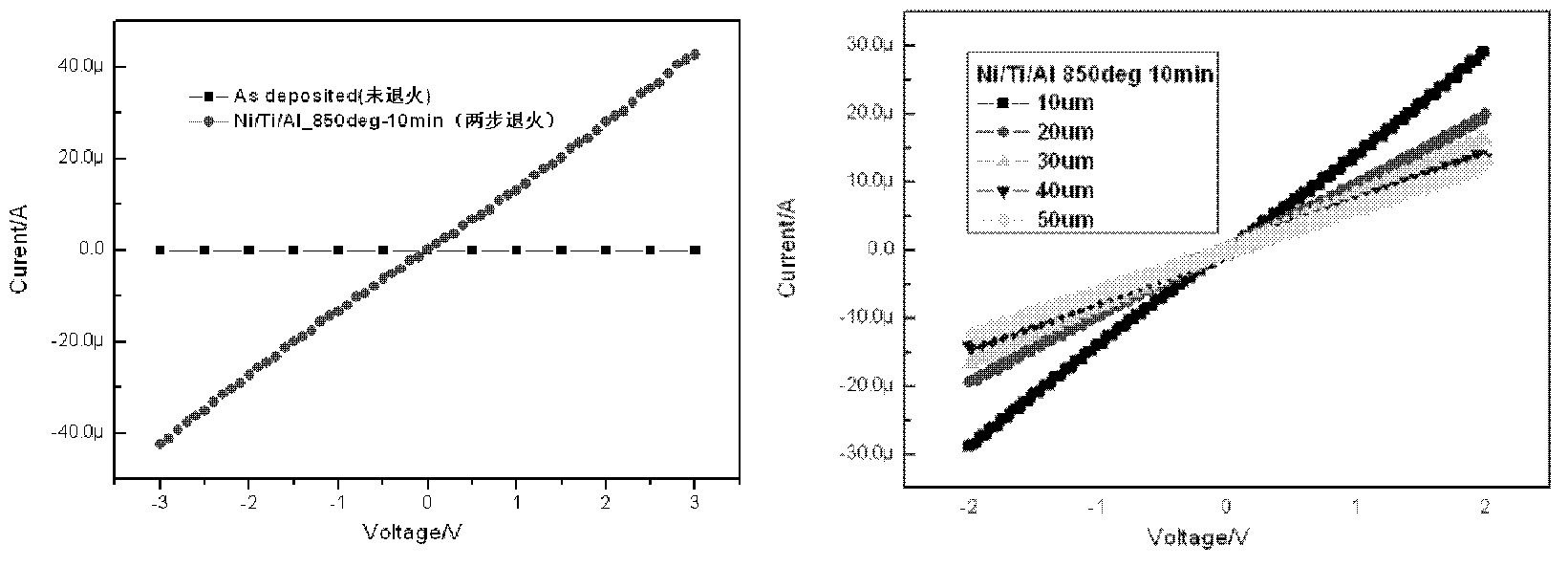

[0020] The present invention proposes a two-step annealing method to realize low-temperature ohmic alloy annealing of P-type SiC materials, by controlling the alloy annealing step, two-step annealing temperature and time, single-step heating rate, single-step cooling rate, and staged cooling temperature The point is to reduce the reaction temperature between the Ti / Al-based contact metal and the P-type SiC interface to achieve good ohmic contact of the P-type SiC material at a lower annealing temperature.

[0021] In order to obtain a good ohmic contact of P-type SiC materials, high-temperature alloy annealing technology has been widely used. Generally, the alloy annealing of Ti / Al-based and silicide ohmic electrodes is be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap