Shaping rack

A technology of bench and positioning groove, which is applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems of difficult steel bar spacing and protective layer thickness, long inspection and verification time, and low operation efficiency, so as to shorten the construction period and promote good promotion The effect of convenient use value and quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

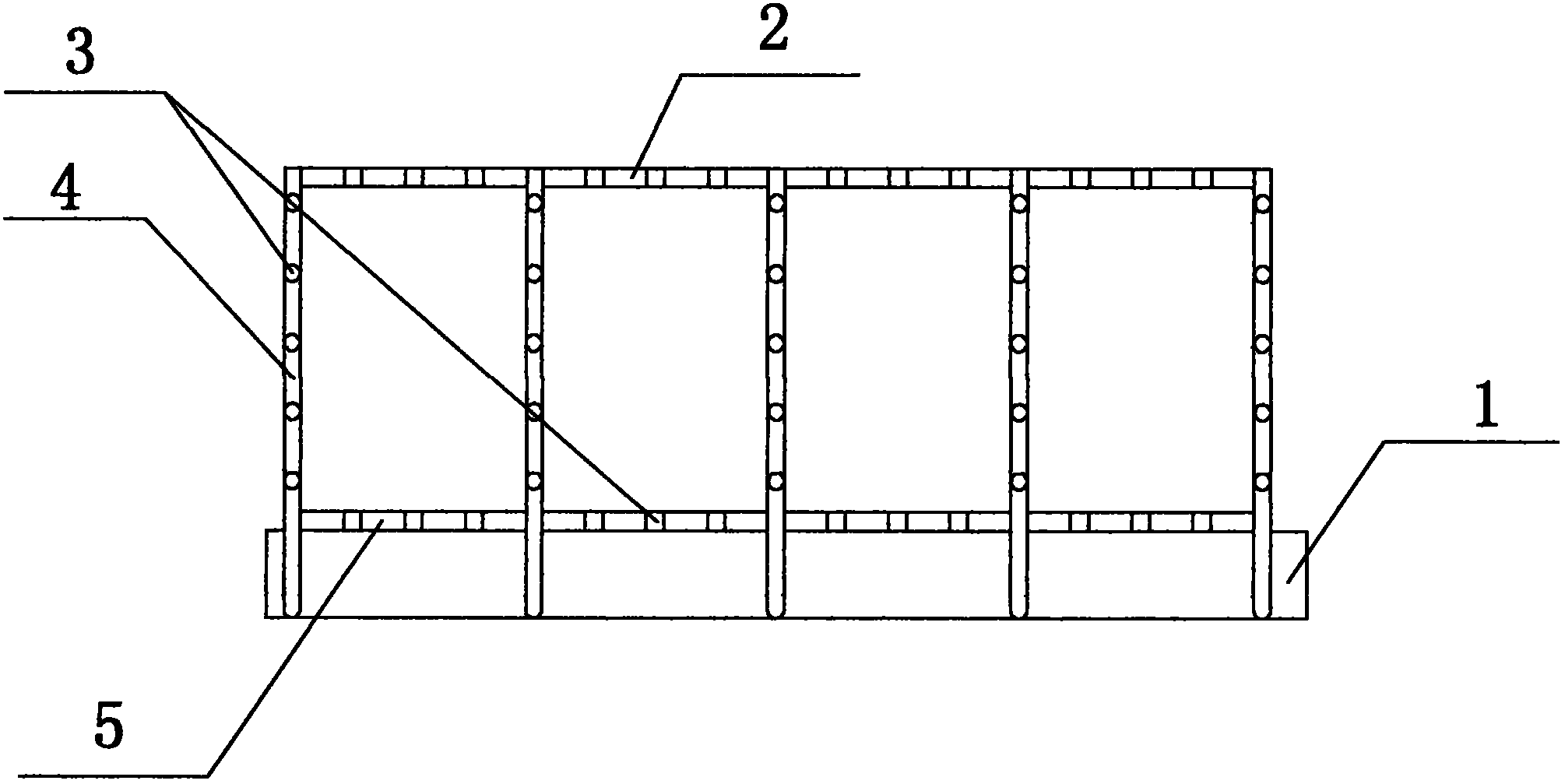

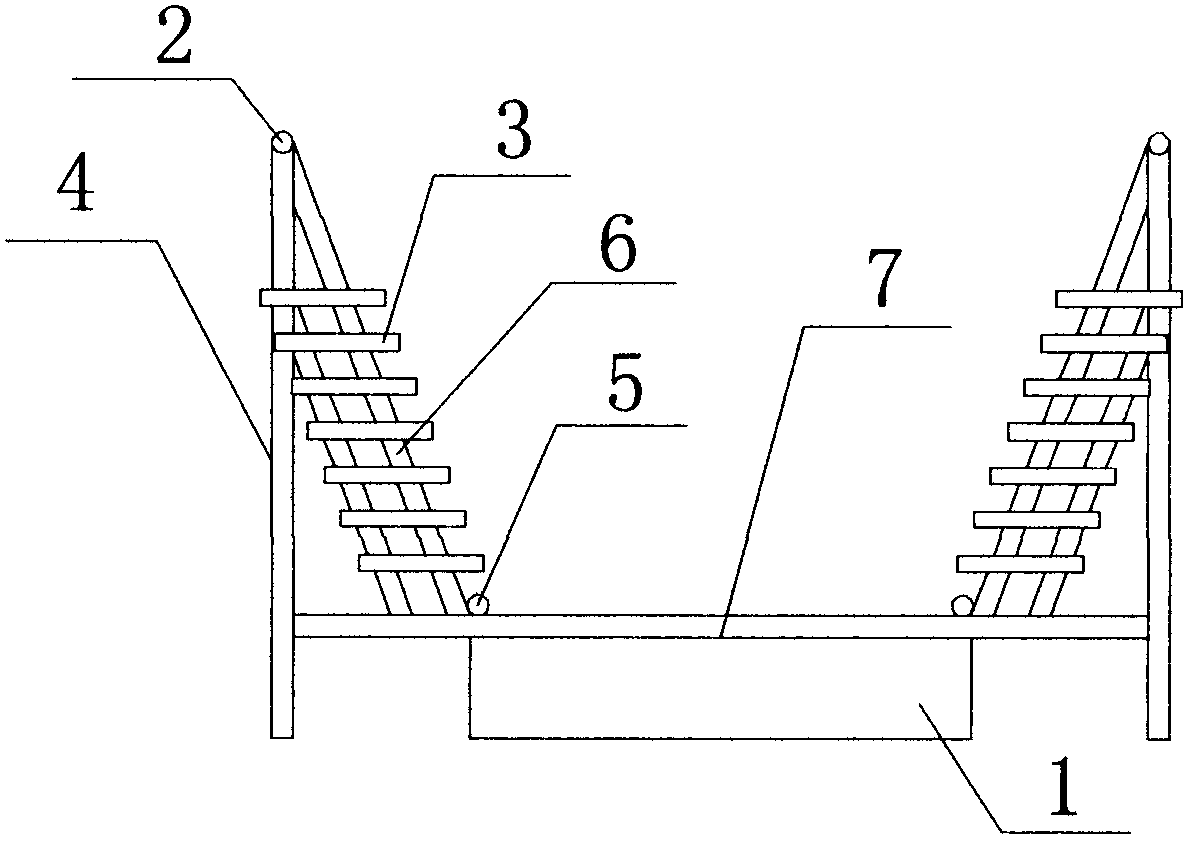

[0013] A shaping stand of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] as attached figure 1 , figure 2 As shown, the above-described shaped bench includes a bench base 1, an integral frame arranged on the bench base 1, and a steel bar positioning groove 3 arranged on the integral frame. The horizontal frame frame 6 and the horizontal frame bottom frame 7 on the frame base 1, two upper vertical frames 2, two lower vertical frames 5 vertically arranged on both sides of the frame base 1, the two lower vertical frames 5 are connected to all The bottom frame of the horizontal frame 7, the two ends of the bottom frame of the horizontal frame 7 extend out of the platform base 1 and are vertically connected with the vertical rod 4, and the top of the vertical rod 4 on each side of the platform base 1 is connected with an upper vertical frame 2, A horizontal frame frame 6 is arranged between the upper vertical frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com