Method for manufacturing metal and plastic composite casing

A production method and metal shell technology, applied in the direction of coating, etc., can solve the problems of unsatisfactory appearance, poor bonding firmness, and difficulty in releasing the buckle structure, so as to maintain gloss and texture, and good tensile resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

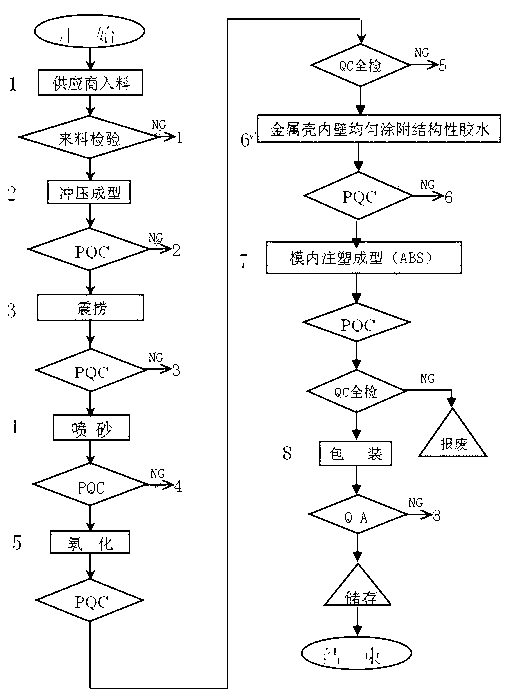

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

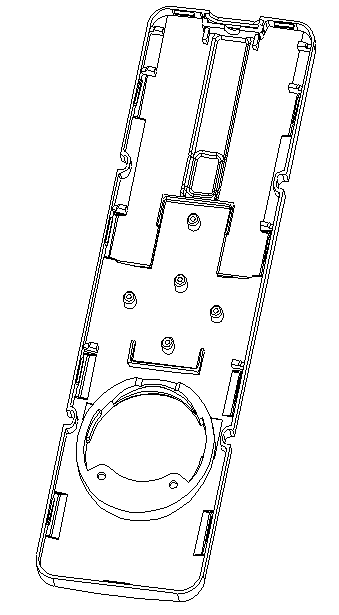

[0042] The invention is mainly applicable to the casing processing of electronic products such as mobile phones, cordless phones and remote controllers.

[0043] The "in-mold injection molding" technology has solved various technical problems in the background technology very well: it refers to that in the process of shell processing, the inner wall of the finished metal shell after stamping and surface treatment is uniformly sprayed with a structural After adding additives, put it in the injection mold, and then inject a layer of plastic material according to the process conditions of injection molding, so that the metal shell and the plastic are tightly combined and inseparable. Usually, it can pass the pull-out force test of more than 80 Newtons .

[0044] working principle:

[0045] During the processing of the shell, the inner wall of the stamped and surface-tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com