Continuously variable transmission system for flow distribution transmission of permanent magnetic speed-regulating planet gear

A technology of planetary gear and stepless speed change, applied in the direction of gear transmission, transmission, transmission control, etc., can solve the problems of not being able to equip high-end cars, increase volume and weight, and large size, and achieve easy automatic control performance, Simple and stepless change, good linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

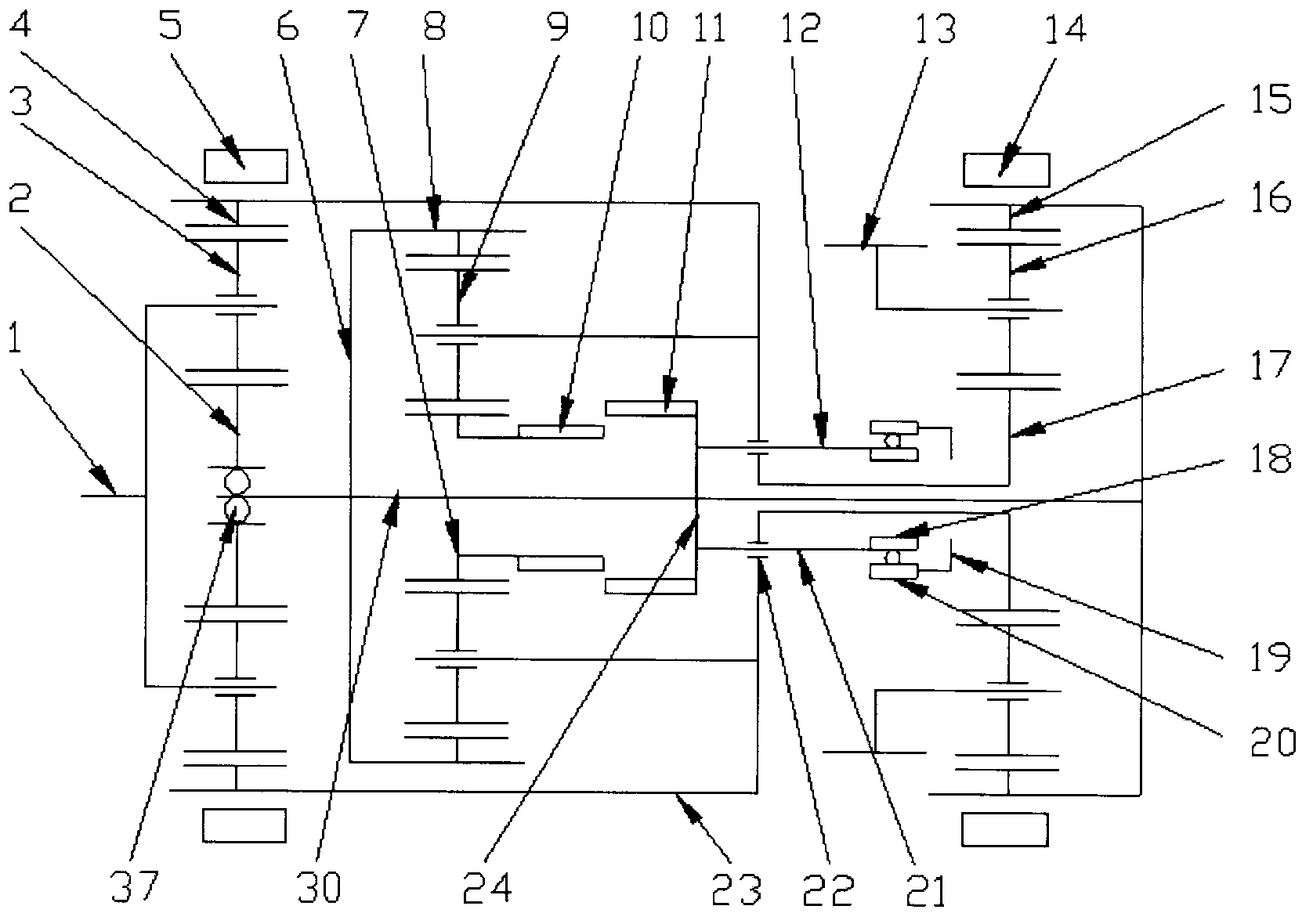

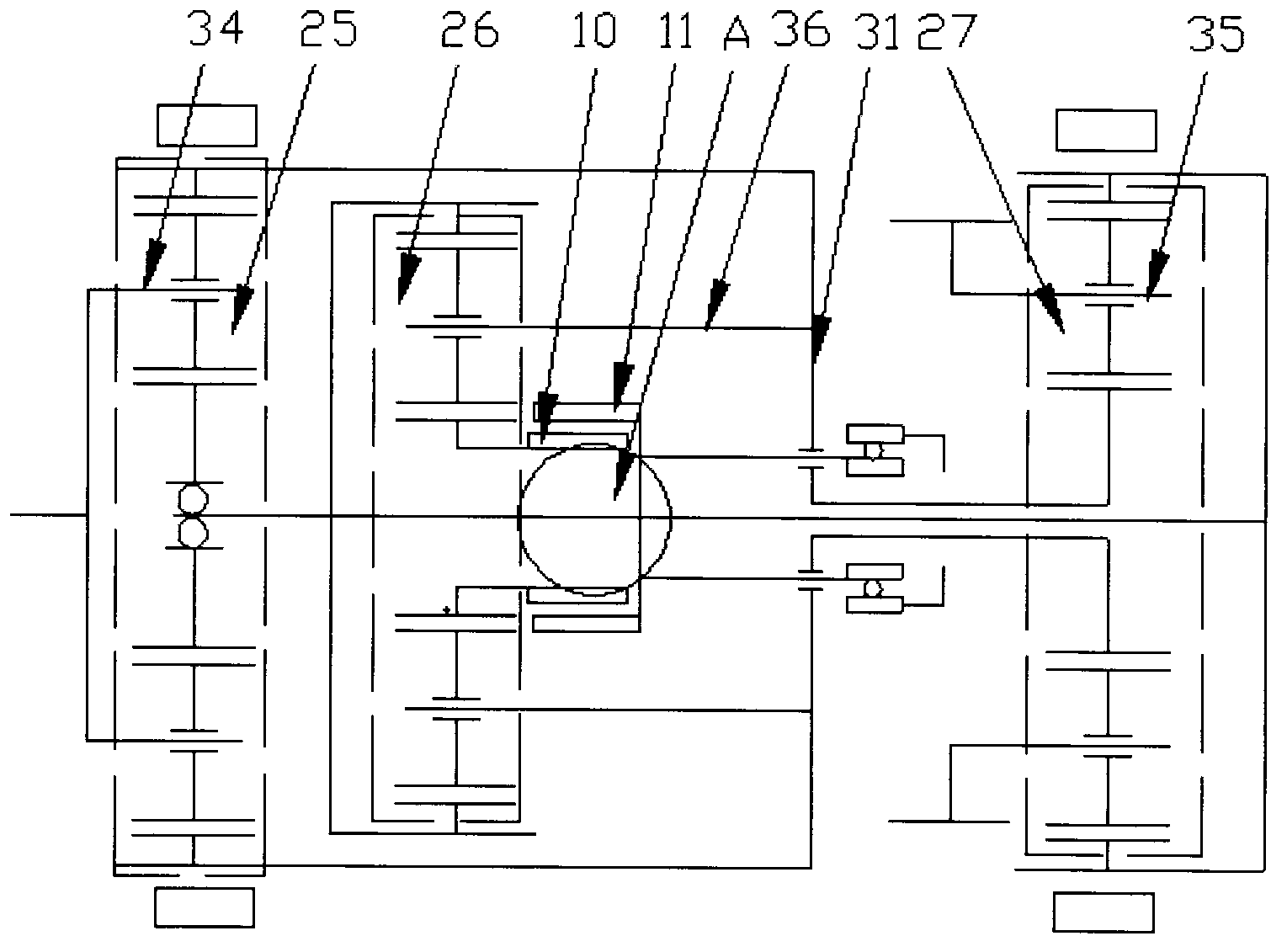

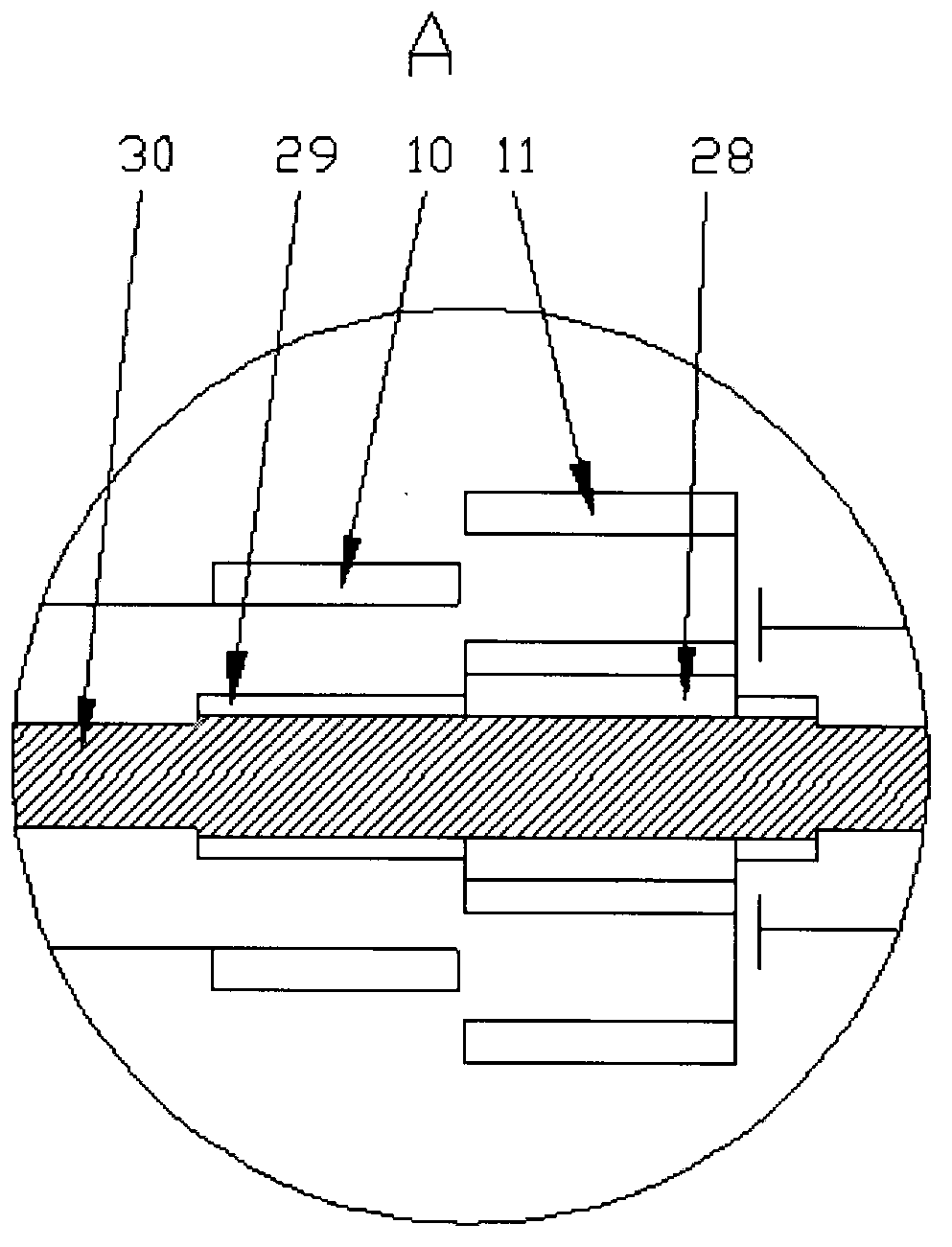

[0021] Referring to accompanying drawings 1 to 6, the structural features of the permanent magnet speed-adjusting planetary gear shunt transmission continuously variable transmission system are (as shown in accompanying drawings 1 to 6): the number of teeth of the front planetary row inner ring gear 4 is 78, and the front planetary row sun The gear 2 has 30 teeth, the front planetary gear 3 has 24 teeth, the rear planetary inner ring gear 15 has 78 teeth, the rear planetary sun gear 17 has 30 teeth, and the rear planetary gear 16 has 24 teeth. The number of teeth of the inner ring gear 8 is 109, the number of teeth of the control planetary row sun gear 7 is 81, the number of teeth of the control planetary row planetary gear 16 is 14, and the size of the long permanent magnet 32 installed in the active part 10 of the permanent magnet transmission is 30mm×10mm×5mm , the size of the wide permanent magnet 33 installed in the driven part 11 of the permanent magnet transmission is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com