Method for measuring water content in crude oil

A technology of water content and crude oil, applied in the field of petroleum industry, can solve the problem of high price, and achieve the effects of stable testing, convenient operation and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

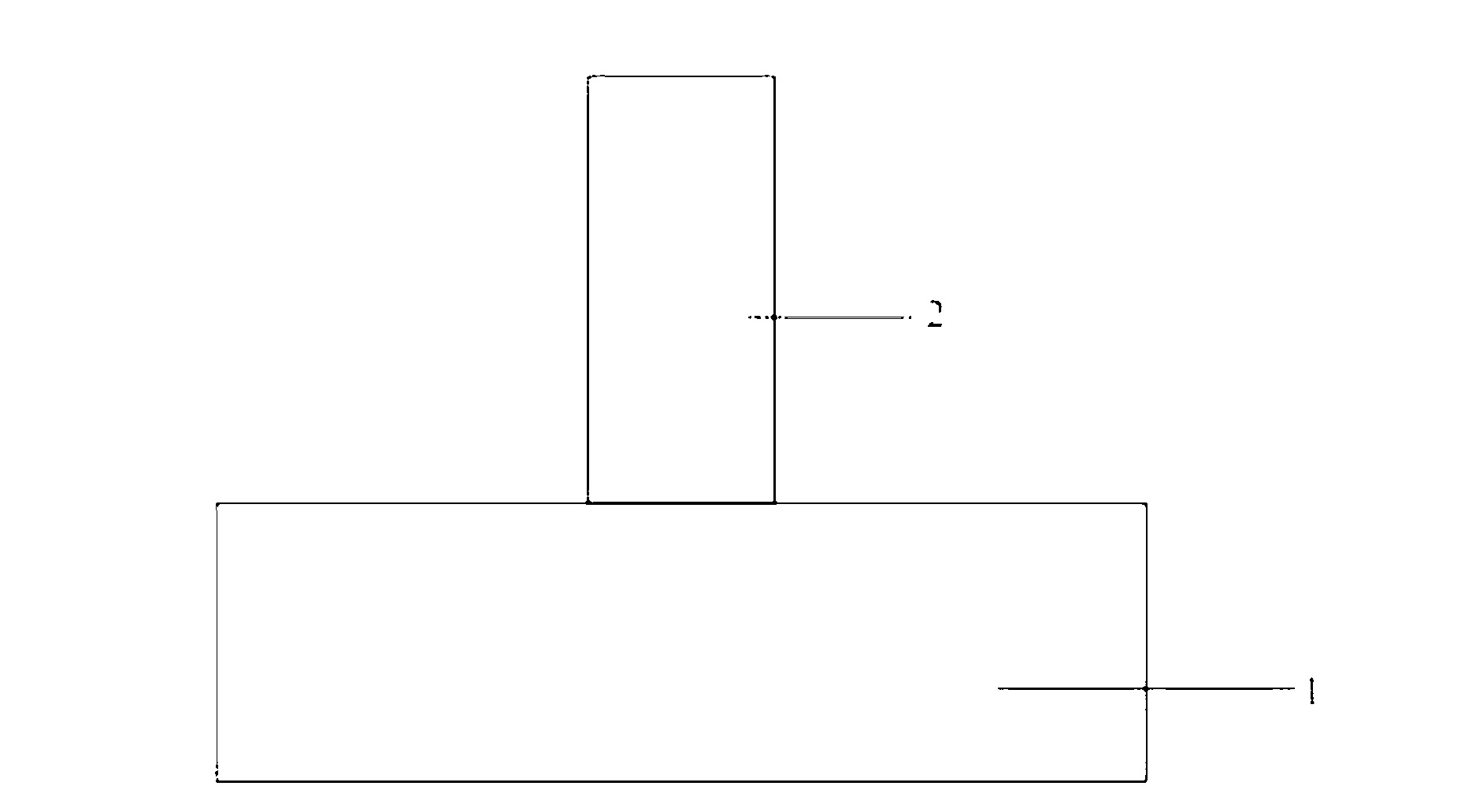

Image

Examples

Embodiment 1

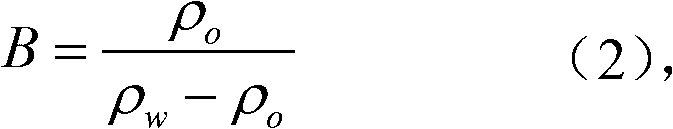

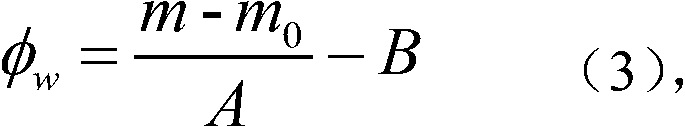

[0043] At 30℃, ρ o =0.7302g.cm -3 As an example, configure a series of oil-water mixture samples with different water content, where ρ w =0.995647g.cm -3 , The configured oil-water mixed sample with known water content is the oil sample to be tested, and the volume V is 10.38cm 3 , Quality m 0 Is 11.6078g pycnometer, according to the formula Calculate the water content of the oil sample to be tested. The specific calculation results are shown in Table 1. When Table 1 is 30℃, the density is 0.7302g.cm -3 The water content measured by formula (3), the parameters of formula (3), the actual water content φ w(s) , Measuring water content φ w(m) , Water content measurement error Δφ w =φ w(m) -φ w(s) .

[0044] According to the test results: the average deviation between the measured water content and the actual value is 0.18%, and the maximum deviation is 0.44%.

[0045] Table 1

[0046]

Embodiment 2

[0048] At 30℃, ρ o =0.8313g.cm -3 As an example, configure a series of oil-water mixture samples with different water content, where ρ w =0.995647g.cm -3 , The configured oil-water mixed sample with known water content is the oil sample to be tested, and the volume V is 10.38cm 3 , Quality m 0 Is 11.6078g pycnometer, according to the formula Calculate the water content of the oil sample to be tested. The specific calculation results are shown in Table 2. When Table 2 is 30°C, the density is 0.8313g.cm -3 The water content measured by formula (3), the parameters of formula (3), the actual water content φ w(s) , Measuring water content φ w(m) , Water content measurement error Δφ w =φ w(m) -φ w(s) .

[0049] According to the test results: the average deviation between the measured water content and the actual value is 0.31%, and the maximum deviation is 0.86%.

[0050] Table 2

[0051]

[0052]

Embodiment 3

[0054] At 30℃, ρ o =0.8847g.cm -3 As an example, configure a series of oil-water mixture samples with different water content, where ρ w =0.995647g.cm -3 , The configured oil-water mixed sample with known water content is the oil sample to be tested, and the volume V is 10.38cm 3 , Quality m 0 Is 11.6078g pycnometer, according to the formula Calculate the water content of the oil sample to be tested. The specific calculation results are shown in Table 3. Table 3 is at 30°C with a density of 0.8847g.cm -3 The water content measured by formula (3), the parameters of formula (3), the actual water content φ w(s) , Measuring water content φ w(m) , Water content measurement error Δφ w =φ w(m) -φ w(s) .

[0055] According to the test results: the average deviation between the measured water content and the actual value is 0.55%, and the maximum deviation is 1.22%.

[0056] table 3

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com