Explosion limit testing device of combustible gas under high-temperature condition

An explosion limit and testing device technology, applied in the direction of material explosiveness, can solve problems such as poor anti-explosion pressure capability and slow heating, and achieve the effect of effective measurement and protection of the testing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

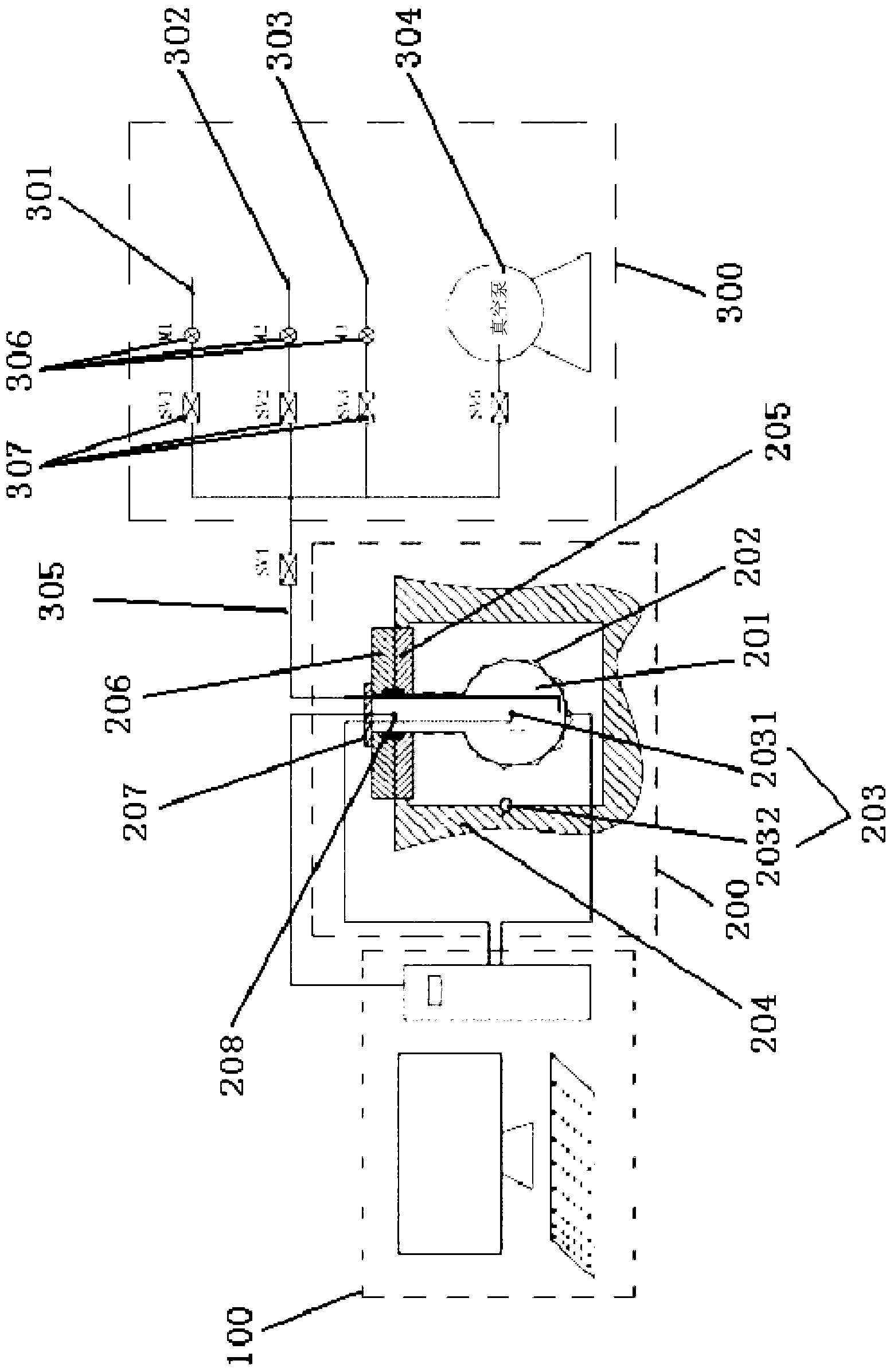

[0026] The device for testing the explosion limit of combustible gas under high temperature conditions of the present invention includes a temperature data acquisition system 100, a heating temperature control system 200 and a gas distribution intake / extraction purge system 300;

[0027] The temperature data acquisition system 100 is a computer receiving and processing system;

[0028] The gas distribution intake / exhaust purge system 300 includes a gas vent pipe 301 to be tested, an oxygen vent pipe 302, an air vent pipe 303 and a vacuum pump 304 connected in parallel;

[0029] The heating temperature control system 200 includes: a round bottom flask test chamber 201, a heating sleeve 202, a temperature control thermocouple 203 and a heating furnace body 204;

[0030] The round bottom flask test chamber 201 is suspended in the heating furnace 204 through an insulating support device 205, the heating sleeve 202 is set on the outer wall of the round bottom flask test chamber 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com