Electrolytic cell with controllable temperature used for electrochemical measurement

An electrolytic cell and electrochemical technology, applied in the direction of material electrochemical variables, etc., can solve problems affecting electrochemical test signals and results, and achieve the effect of simple and convenient disassembly and replacement of samples, beautiful appearance, and avoiding corrosion and rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

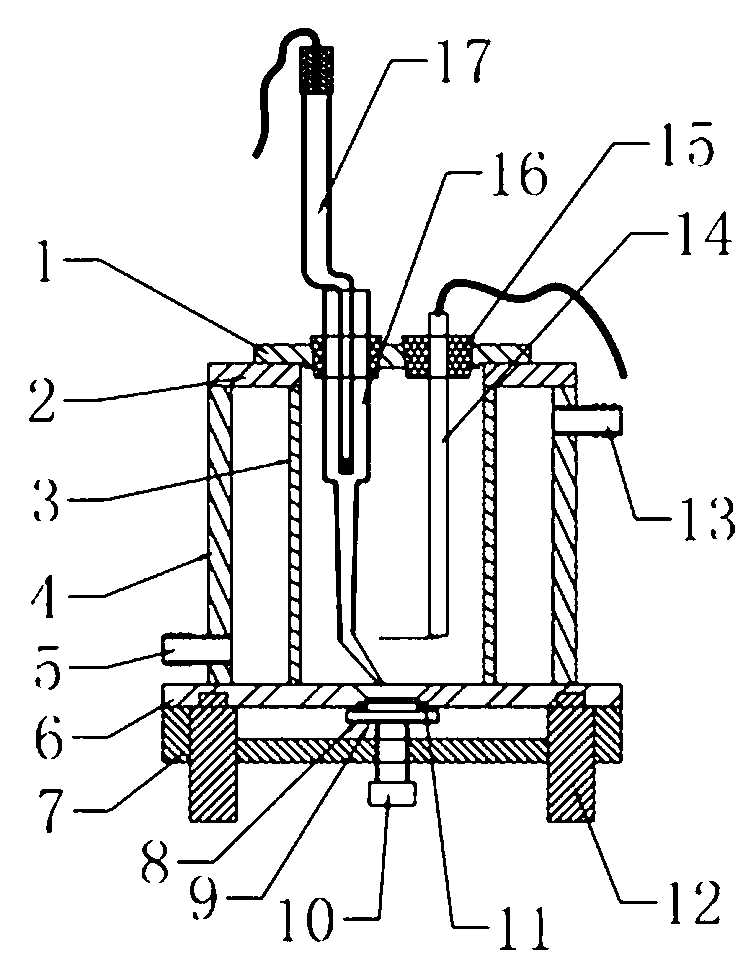

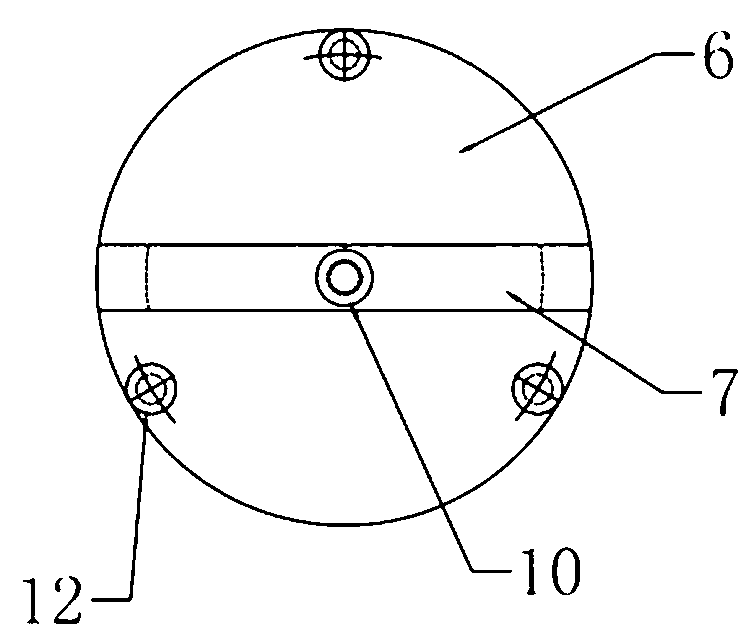

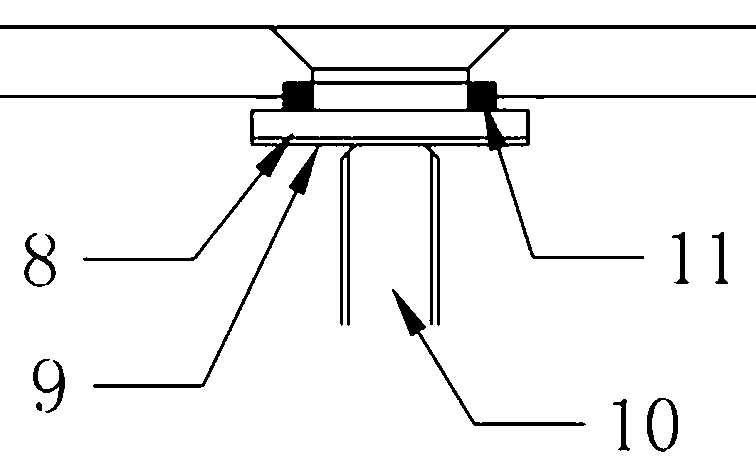

[0010] In the present invention, the upper cover plate (1), the casing top plate (2), the electrolytic cell (3), the circulating water casing (4), the water inlet (5), the casing bottom plate (6), the fixed support plate (7), The fastening bolts (10), the container feet (12) and the water outlet (13) are all made of colorless and transparent plexiglass.

[0011] The electrolytic cell (3) and the circulating water casing (4) are two plexiglass cylindrical tubes, the casing top plate (2), the electrolytic cell container (3), the circulating water casing (4), the water inlet (5), The casing bottom plate (6), the fixed support plate (7), the container feet (12), and the water outlet (13) are firmly bonded with plexiglass glue. Ensure that the casing top plate (2) and the electrolytic cell (3) , Circulating water casing (4), water inlet (5), casing bottom plate (6), and water outlet (13) are not leaking at the joints.

[0012] The inner side of the upper cover plate (1) is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com