Asymmetric electrochemical capacitor and its preparation method

An electrochemical and asymmetric technology, applied in the field of capacitors, which can solve the problems of low specific capacitance of capacitors, low energy density of capacitors, and inability to form effective capacitances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

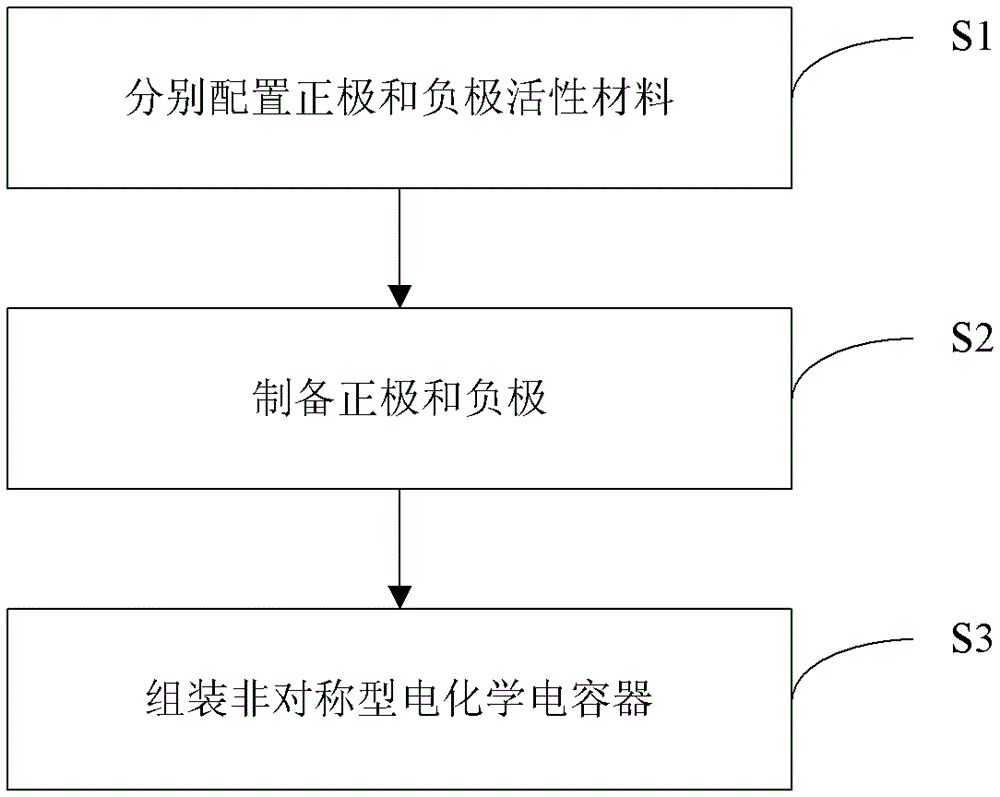

[0033] Another object of the present invention is to provide the preparation method of above-mentioned asymmetric type electrochemical capacitor, such as figure 2 shown, including the following steps:

[0034] S1. Configure the metal oxide, the first conductive agent, and the first binder with a mass ratio of 80 to 93:2 to 10:5 to 10 as the positive electrode active material, and set the mass ratio to 80 to 93:2 ~10:5~10 graphene, the second conductive agent and the second binder are configured as the negative electrode active material;

[0035] S2. Coating the positive electrode active material on an aluminum foil and drying it to obtain a positive electrode; coating the negative electrode active material on a copper foil and drying it to obtain a negative electrode;

[0036] S3. Cut the positive electrode, negative electrode, and separator into required specifications, then cut them into required specifications, assemble them in the order of positive electrode / diaphragm / ne...

Embodiment 1

[0047] 1. Electrode preparation of asymmetric electrochemical capacitor:

[0048] positive electrode. Mix NiO with a mass ratio of 85:10:5, acetylene black conductive agent, and PVDF binder to make a positive electrode active material, coat the positive electrode active material on an aluminum foil, and bake it in a vacuum at 80°C for 12 hours to obtain a positive electrode ;

[0049] negative electrode. Graphene with a mass ratio of 85:10:5 (with a specific surface area of 400m 2 / g), acetylene black conductive agent, and PVDF binder are mixed to make a negative electrode active material, and the negative electrode active material is coated on a copper foil, and baked in a vacuum at 80° C. for 12 hours to obtain a negative electrode.

[0050] Wherein, the mass ratio of the positive electrode active material on the positive electrode to the negative electrode active material on the negative electrode is 1:1.

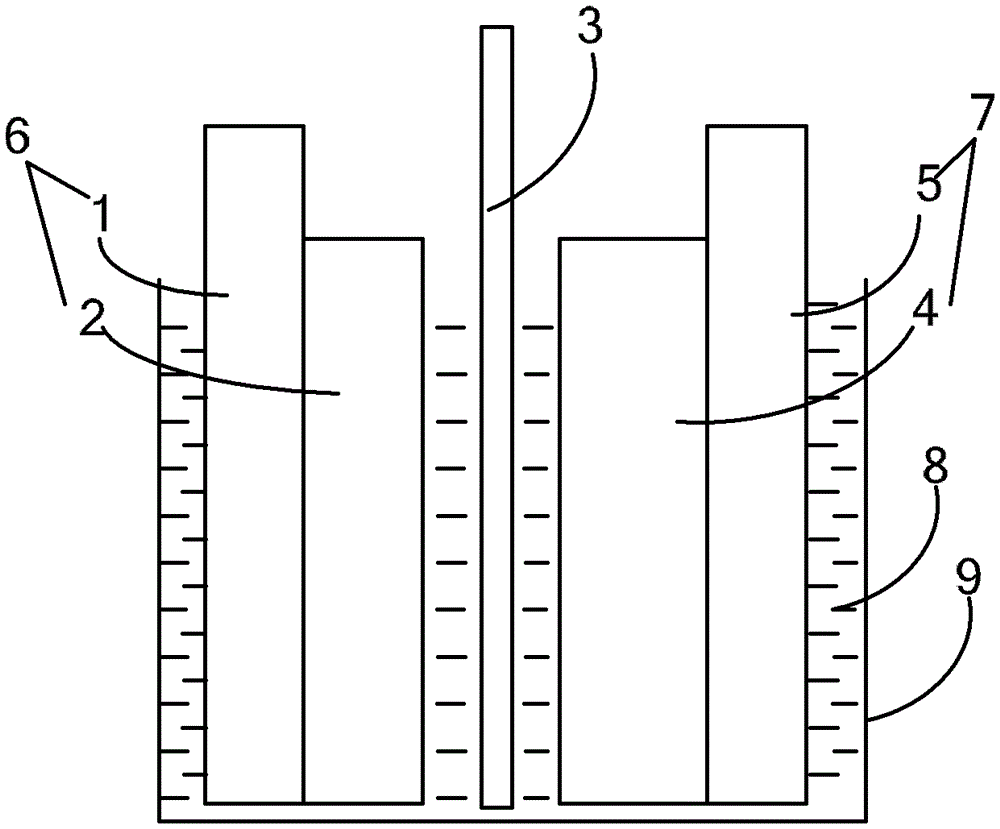

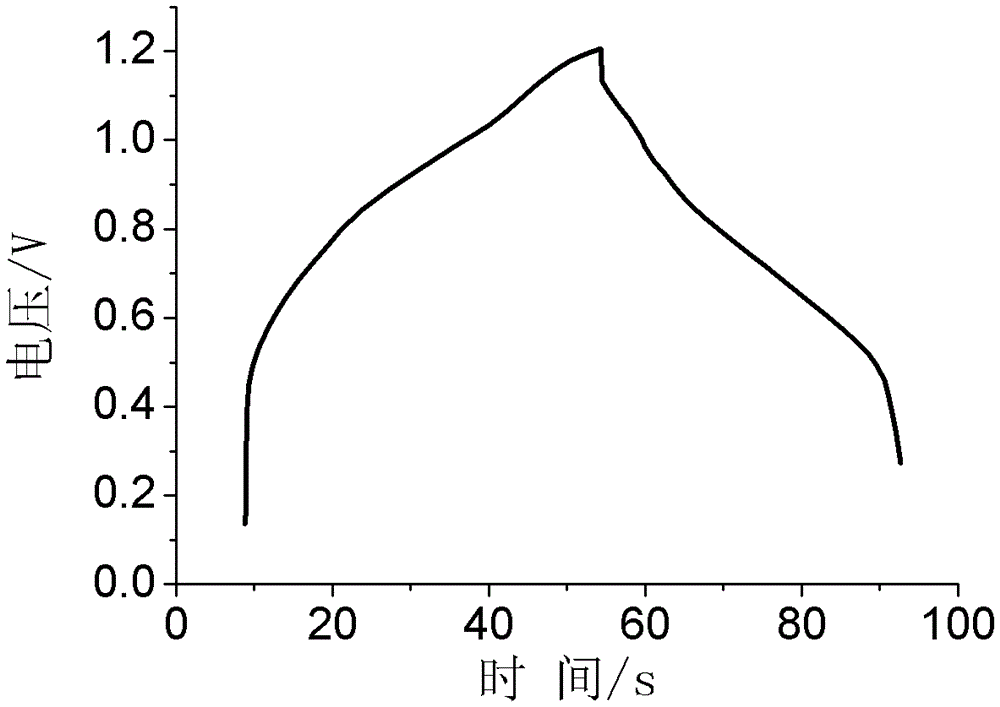

[0051] 2. Assembly of asymmetric electrochemical capacitors: ...

Embodiment 2

[0055] 1. Electrode preparation of asymmetric electrochemical capacitor:

[0056] positive electrode. PbO with a mass ratio of 80:10:10 2 , carbon nanotube conductive agent, and PVDF binder are mixed to make a positive electrode active material, and the positive electrode active material is coated on an aluminum foil, and baked in a vacuum at 80°C for 12 hours to obtain a positive electrode;

[0057] negative electrode. Graphene with a mass ratio of 80:10:10 (specific surface area of 700m 2 / g), a carbon nanotube conductive agent, and a PVDF binder are mixed to make a negative electrode active material, and the negative electrode active material is coated on a copper foil, and baked in a vacuum at 80° C. for 12 hours to obtain a negative electrode.

[0058] Wherein, the mass ratio of the positive electrode active material on the positive electrode to the negative electrode active material on the negative electrode is 1:2.

[0059] 2. Assembly of asymmetric electrochemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com