Jointing clamp with self-locked taper

A terminal clamp and taper technology, applied in the direction of connection, connection insulation, conductive connection, etc., can solve the problems of cumbersome wiring process, poor contact surface between wires, and easy loosening of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

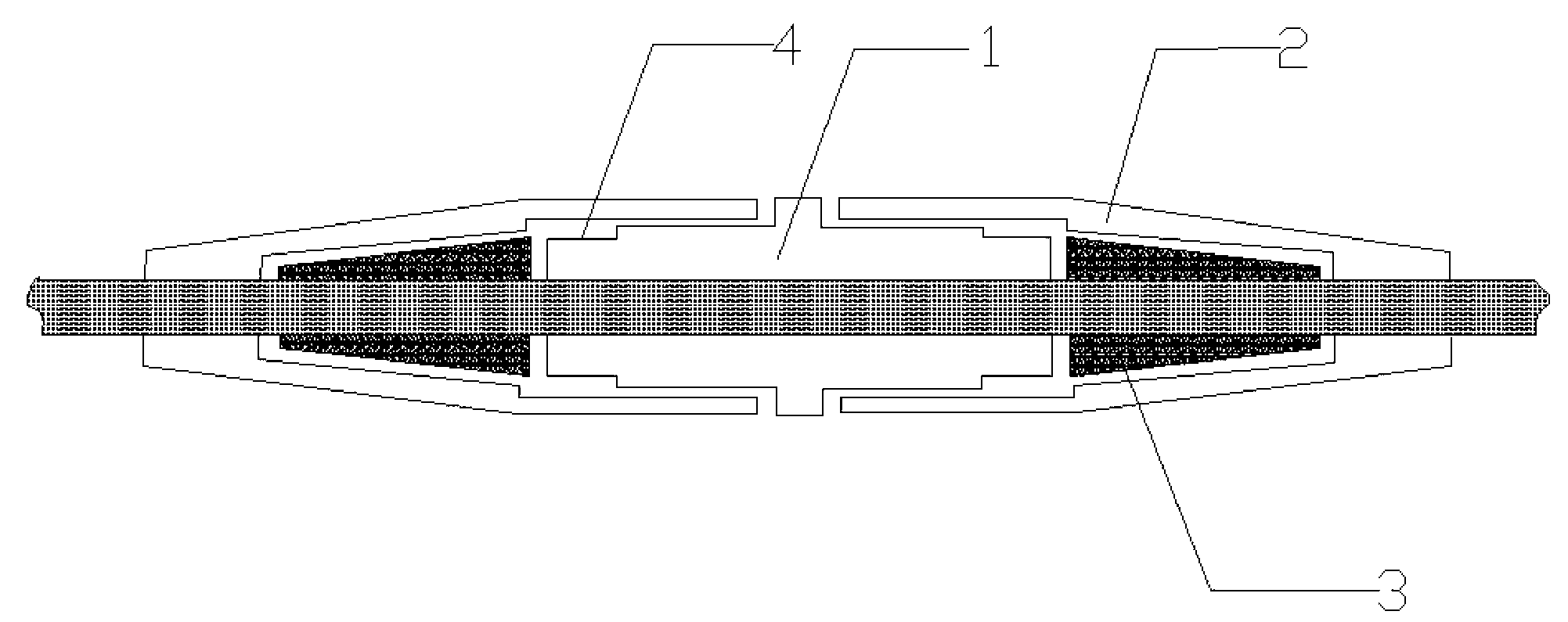

[0007] A tapered self-locking clamp includes a threaded connection device (1), a tapered self-locking device (3), and a nut connection device (2). The threaded connection device (1) is connected to the nut connection device (2) through threads, The nut connecting device (2) is set on the threaded connecting device (1), and there are adjusting tightening devices (4) at both ends of the threaded connecting device (1), and the threaded connecting device (1) is connected with the nut connecting device (2) When tightening, adjust the jacking device (4) to move forward, and push the taper self-locking device (3) forward along the inside of the nut connection device (2) to clamp the wires; the nut connection device (2) The connection with the threaded connection device (1) is cylindrical, and the outer end is conical, forming a taper self-locking device with the taper self-locking device (3). Under the push of the adjustment jacking device (4), the taper self-locking device ( 3) Slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com