Fault-tolerant linear motor capable of reducing and saving permanent-magnet material

A permanent magnet material and linear motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of serious magnetic flux leakage, reduce mutual inductance, improve utilization rate, and solve the effects of serious magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

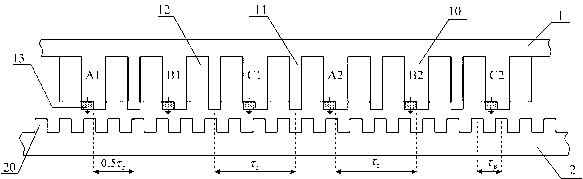

[0017] The core electromagnetic structure of the magnetic flux reversal linear motor of the present invention is shown in Figure 2. In order to explain the present invention more clearly, the pole-slot ratio of the linear motor of the present invention is embodied. According to the formula proposed above, the motor can be obtained It is three-phase, the number of armature teeth is N s 6, the number of secondary teeth N p is 20, the ratio of armature tooth pitch to secondary pitch is 20 / 6.

[0018] The magnetic flux reversal motor mechanism of the present invention is shown in FIG. 2 , which includes a primary 1 and a secondary 2. The primary includes armature teeth 10 wound with coils, fault-tolerant teeth 11 , winding coils 12 , and permanent magnets 13 .

[0019] The secondary 2 is composed of evenly distributed salient pole teeth 20 of equal width, and has a sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com