Test platform for cutting mechanism of cutting tooth on rock

A test platform and pick technology, applied in the direction of stone processing tools, stone processing equipment, working accessories, etc., can solve the problem of unstable test conditions, rock process test instruments can not approach the field conditions, and can not meet the theoretical analysis of the pick Needs and other issues to achieve the effect of perfect function, high control precision and large test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

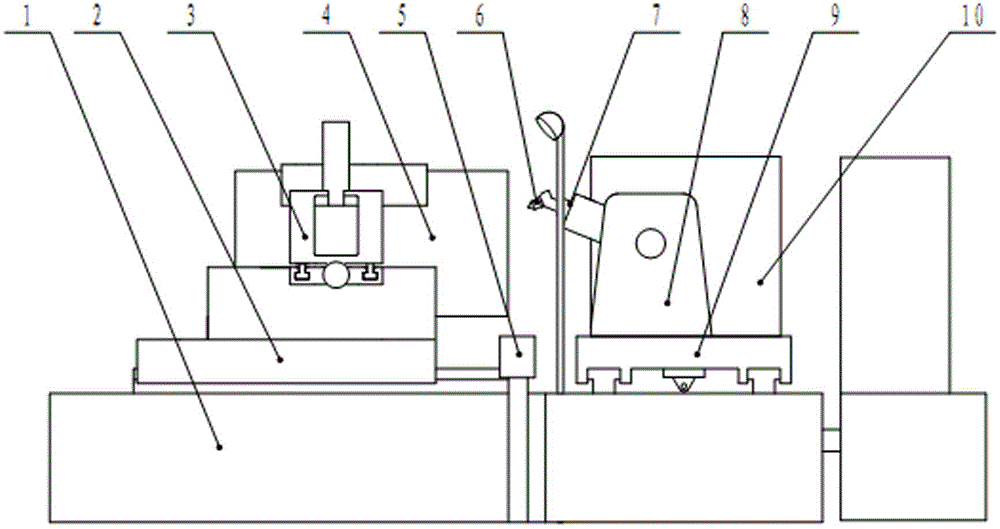

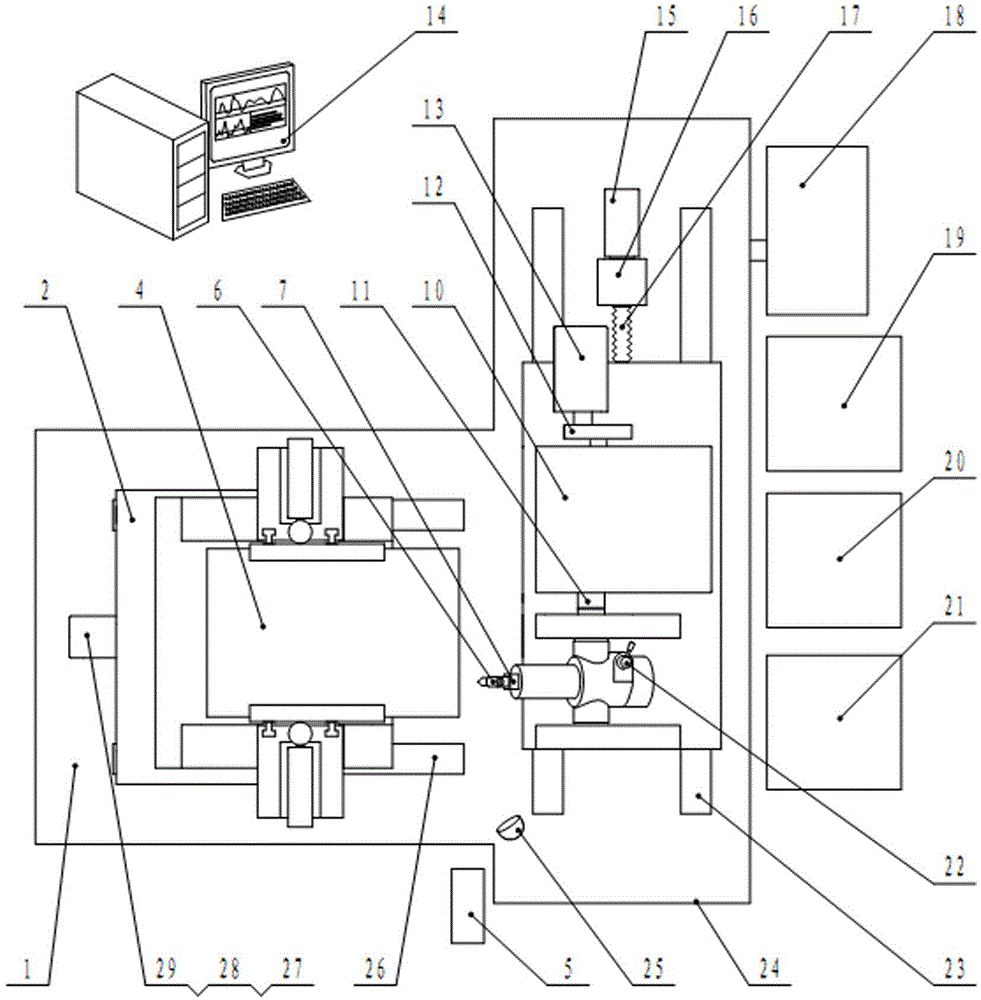

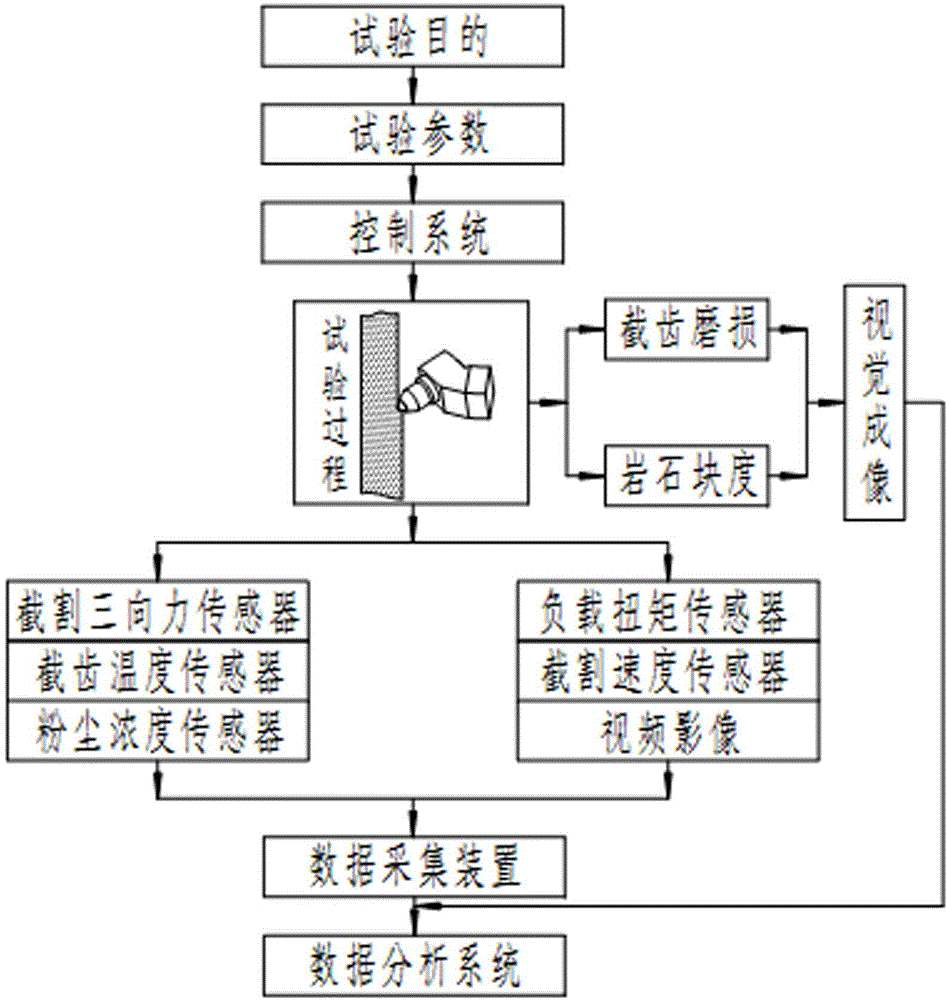

[0032] Such as figure 1 , figure 2As shown, the pick-to-rock cutting mechanism test platform includes a base on which a stone material moving guide rail and a tool holder moving guide rail are arranged. The stone material moving guide rail and the tool holder moving guide rail are perpendicular to each other and include two parallel tracks respectively. A stone table is set on the above-mentioned stone moving guide rail, the outside of the stone table is connected to the stone table driving motor through a stone table driving screw, and a stone clamping device is arranged on the stone table.

[0033] Such as Figure 4 As shown, the stone clamping device includes a fixture platform and a height adjustment part of the fixture platform. The fixture platform includes a grooved platform in the middle and shoulders on both sides. The shoulders are V-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com