Preparation method of transparent aerogel

An airgel and gel technology, applied in the field of airgel, can solve the problems of no flame retardancy, deformation, high porosity, etc., and achieve the effects of reducing shrinkage deformation, broad application prospects, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

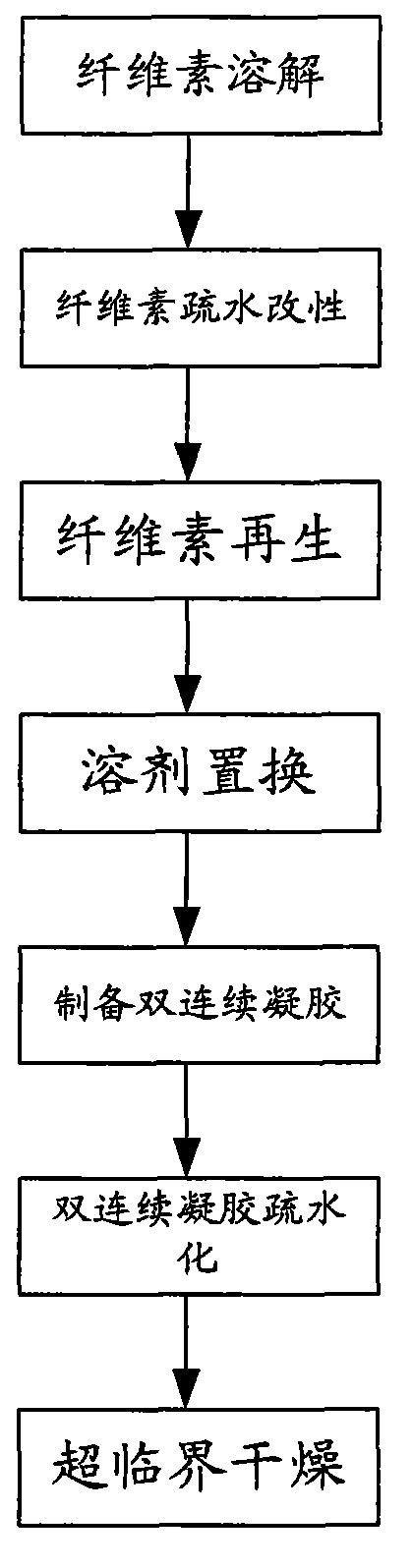

Method used

Image

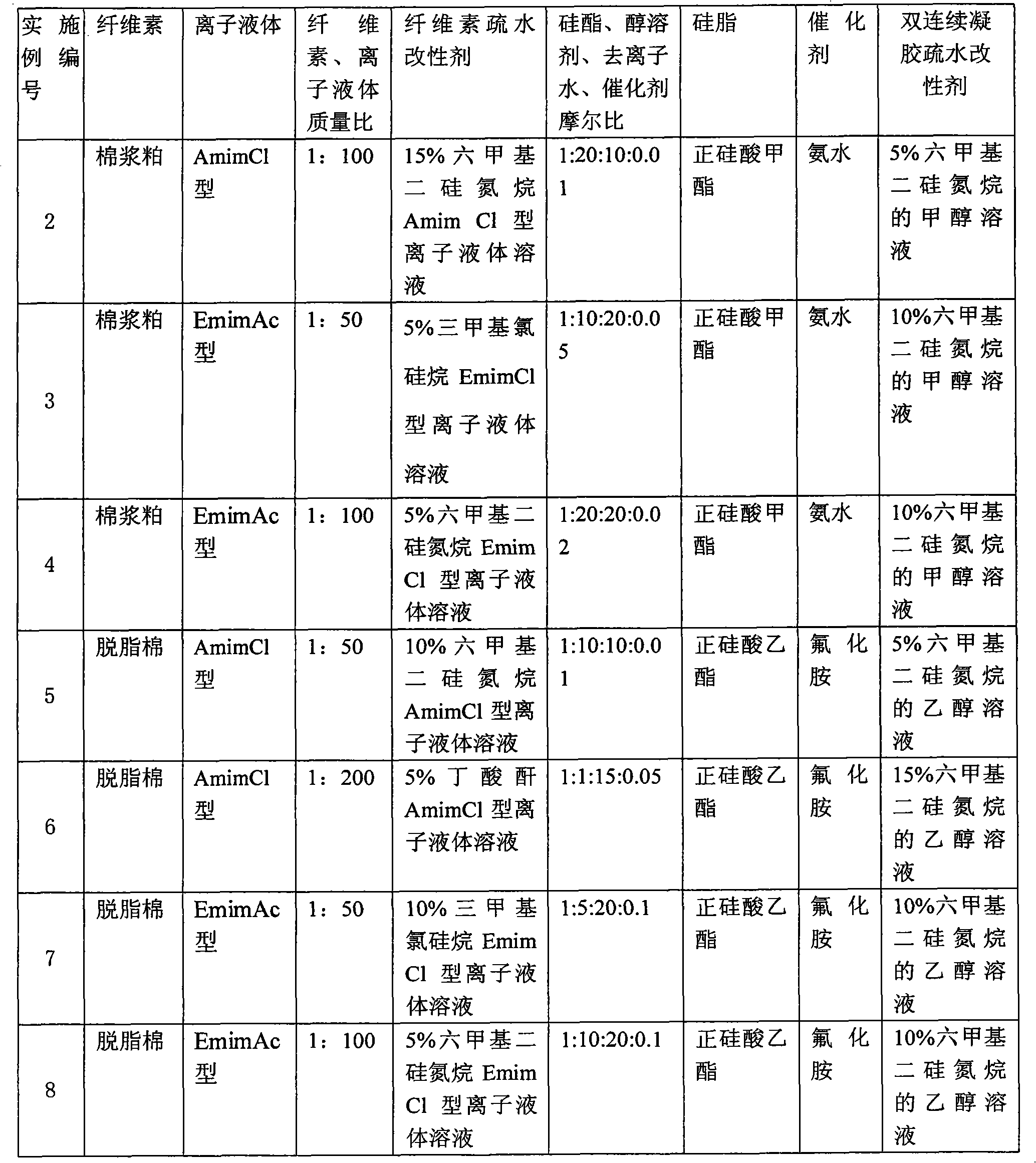

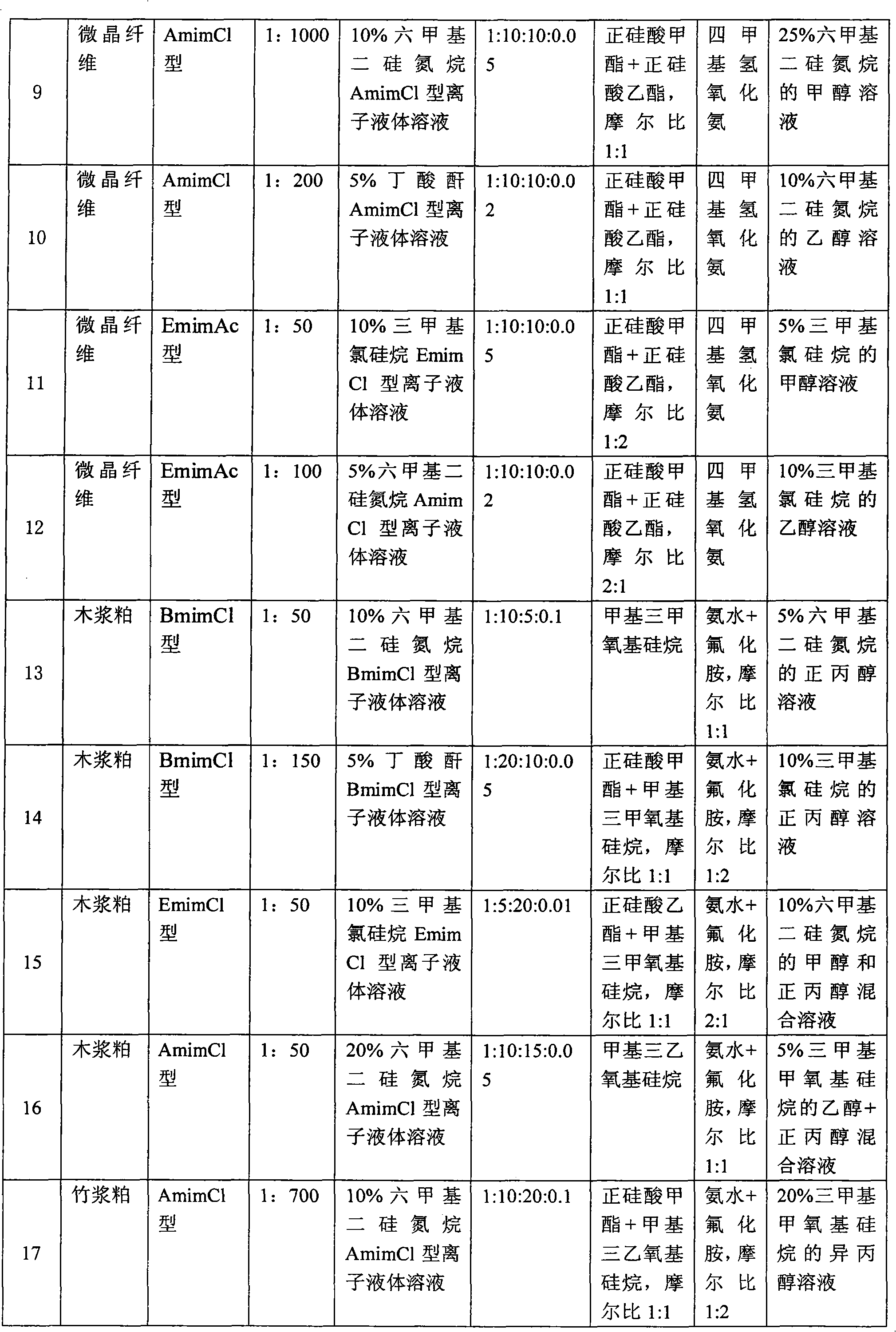

Examples

Embodiment 1

[0043] 1. Add 2kg of AmimCl-type ionic liquid to the vacuum kneader, raise the inner cavity temperature of the kneader to 80°C, add 20g of cotton pulp, and stir for 1 hour under vacuum to obtain a uniform and transparent cellulose solution.

[0044] 2. Keeping the temperature constant, add 500 g of AmimCl-type ionic liquid solution with a volume fraction of 10% butyric anhydride under stirring, and continue stirring for 20 minutes.

[0045] 3. Keep the conditions unchanged and vacuumize for 15 minutes. Pour the above-mentioned cellulose solution into the mold, let it stand, and take it out after gelling.

[0046] 4. Rinse the gel with deionized water and sequentially replace it with absolute ethanol to obtain a cellulosic alcohol gel.

[0047] 5. Replace the ethanol in the mold with the same volume of orthosilicate methyl ester, absolute ethanol, deionized water, and catalyst. The ratio is: orthosilicate methyl ester: absolute ethanol: deionized water: ammonia water = 1:10 :...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com