Process for manufacturing oil by cold-squeezing of rape seeds

A rapeseed, cold-pressed technology, applied in the production of fat/fat, fat production, etc., can solve the problems of poor accuracy, affecting the processing of rapeseed cake, low separation efficiency, etc., and achieve the effect of improving noise and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

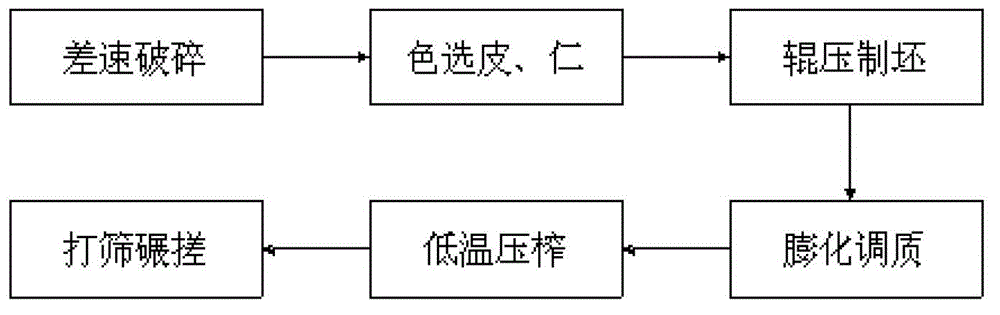

[0013] Such as figure 1 Shown, the cold-pressed oil making process of rapeseed comprises the following steps:

[0014] a. The raw material rapeseed is crushed, using differential speed rollers to implement differential speed crushing;

[0016] c. Color sorting and separation of skin and kernel;

[0017] d, then rolling the blank;

[0018] e. Low temperature puffing and tempering;

[0019] f. Low temperature pressing.

[0020] Among the above technical solutions, the most important thing is the color separation of skin and kernel. By identifying the color of skin and kernel, the raw material of skin and kernel will slide down from the guide groove arranged obliquely for the raw material to slide down, and the pressure gas will be aimed at the material to be separated. Part of one of the colors in the material is sprayed, and it is collected under the separated material, so that the material is separated, that is, the skin and kernel are separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com