Manufacturing method for end shield of built-in grout block shield machine

A manufacturing method and grouting block technology, which are used in earth-moving drilling, mining equipment, tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] production preparation

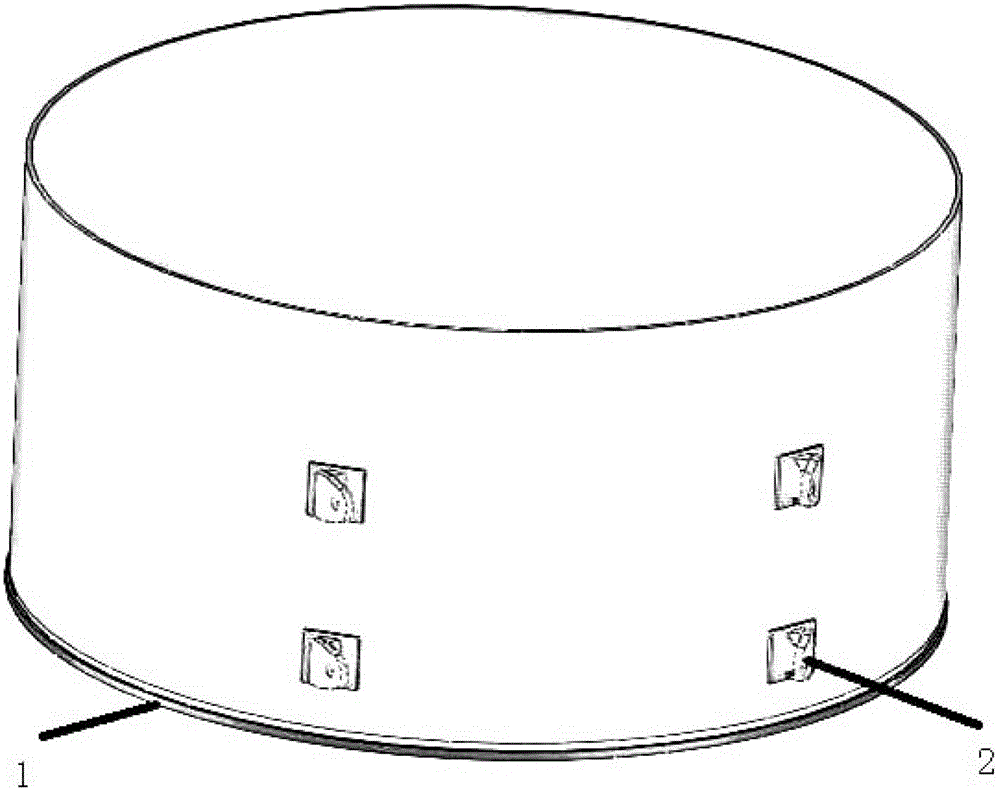

[0050] Weld an adjustable inner tube flange at the front end of the cylinder, and make the front end face down, and then weld lifting lugs and temporary lifting lugs, such as figure 1 shown.

[0051] Tailor welding of long and short pressure plates

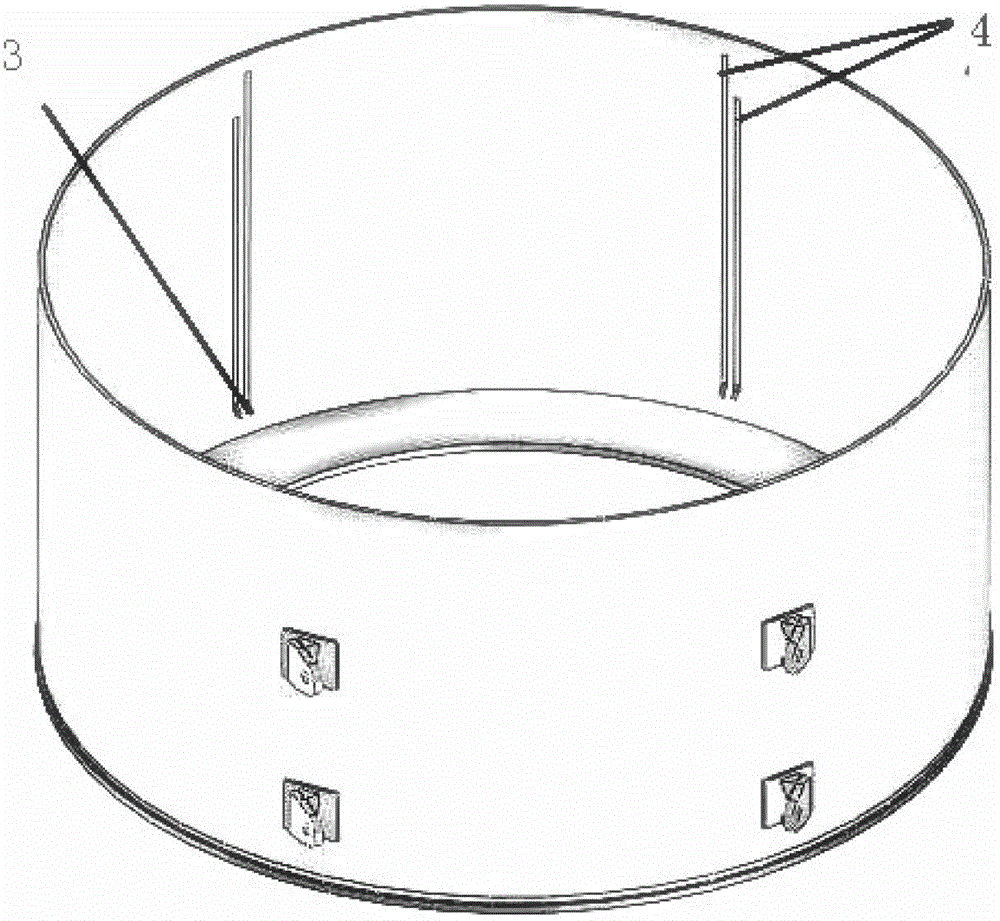

[0052] Weld long and short pressure plates, grease pipes, etc. outside the grease tank. After the welding is completed, carry out a hydraulic test on the cavity formed by the pressure plate and the shell. The test pressure is 10 bar. It is required that the pressure drop within 30 minutes does not exceed 0.5 bar. figure 2 shown.

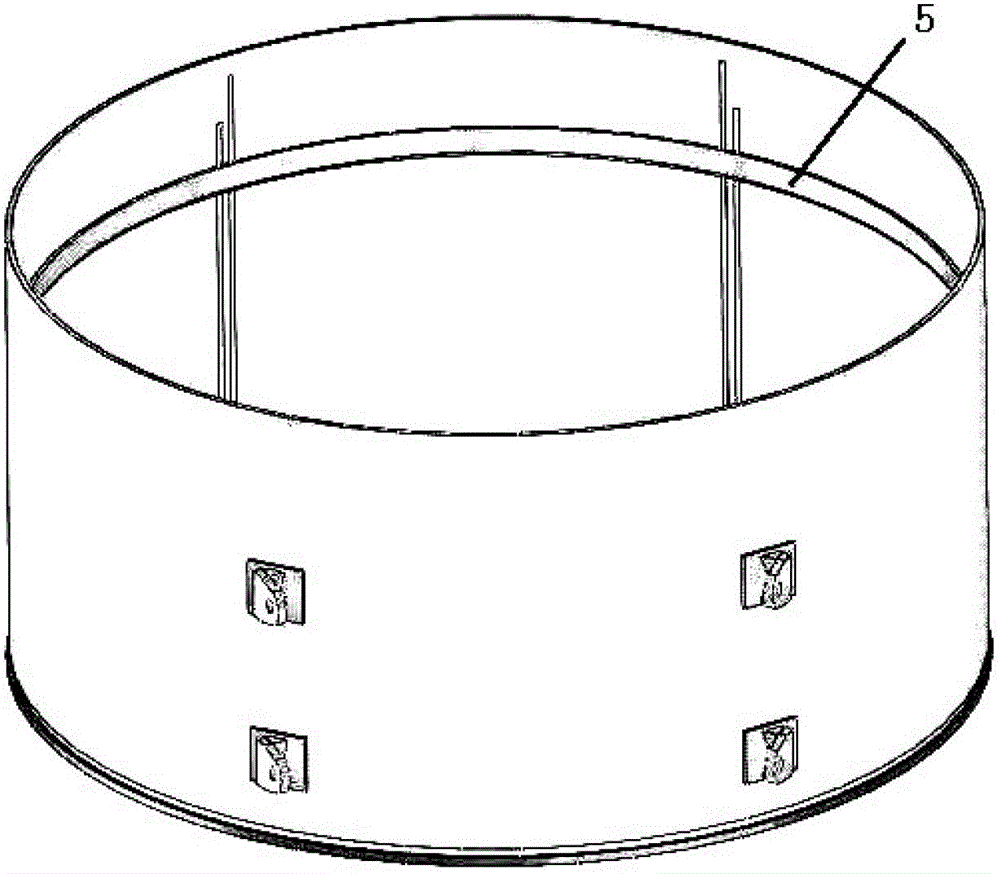

[0053] Install the reinforcement ring 1

[0054] After the reinforcement ring is rounded, the internal support is provided, and the reinforcement ring must be tightly attached to the cylinder with a gap of no more than 1mm. Then draw a line based on the front end of the cylinder and then weld symmetrically. Pay special attention to the fact that the position of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com