Circulating fluidized bed boiler material layer control system and control method

A technology of fluidized bed boiler and circulating fluidized bed, which is applied in the field of circulating fluidized bed boiler control and boiler automatic control system to achieve the effect of optimizing operation mode, realizing automatic control and improving waste heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

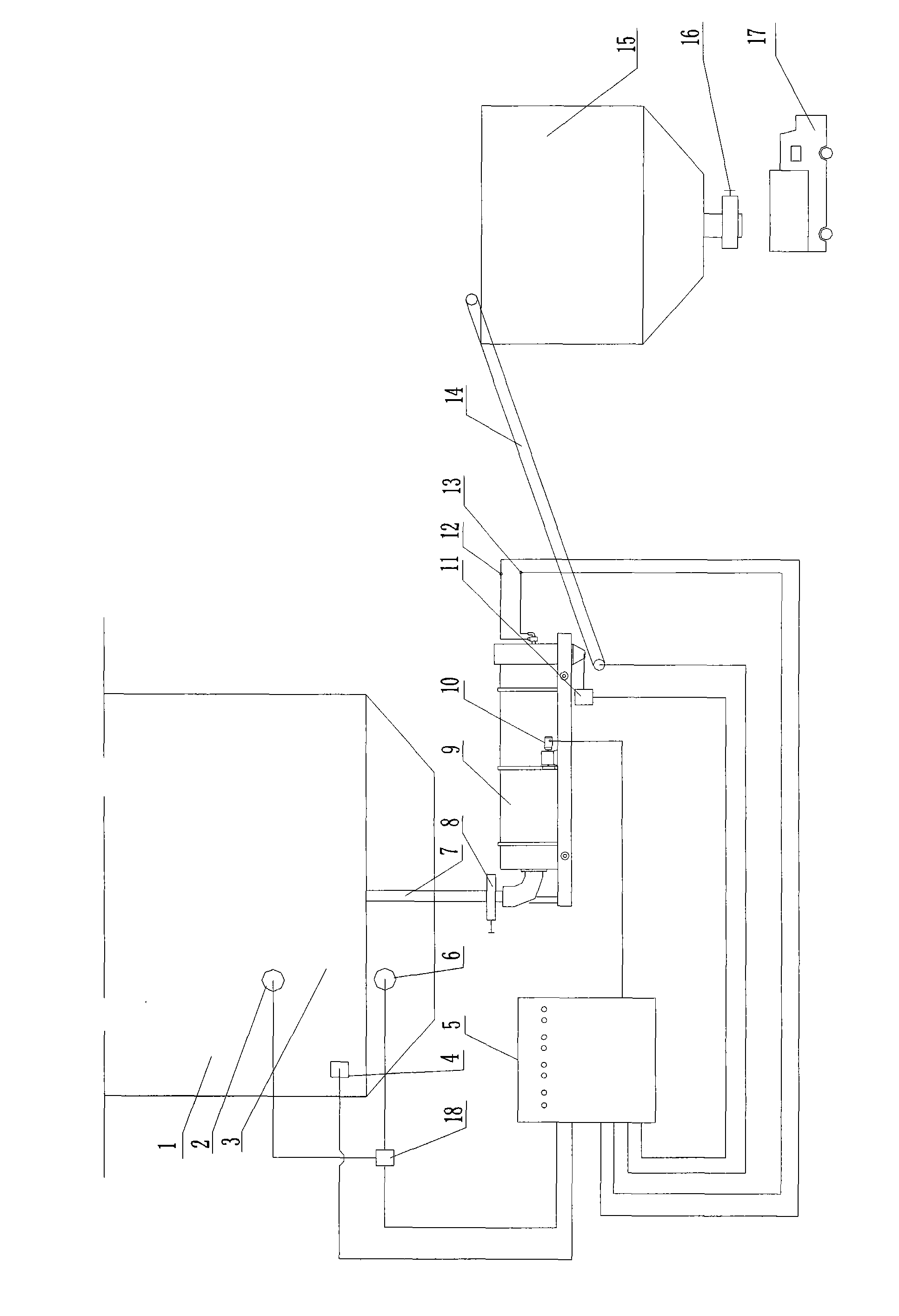

[0035] Design a factory circulating fluidized bed boiler 1x75t / h, adopt the automatic control method of the material layer of the present invention, its technological process is as follows figure 1 shown.

[0036] The specific design basis is as follows:

[0037] During normal production, the coal consumption of a single boiler is less than 14t / h;

[0038] Boiler slag discharge <8.5t / h;

[0039] The thickness of the material layer is 500mm, and the differential pressure of the material layer is 7-9KPa;

[0040] Cooling water volume of slag cooler 10—34t / h

[0041] Implement the method that the present invention applies PLC control system to implement the automatic control of material layer in circulating fluidized bed boiler:

[0042] When the boiler is in normal operation, after checking that the slag discharge system meets the opening conditions, open the water inlet and outlet valves of the slag cooler and pass water, then open the slag valve 8, start the PLC control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com