Vacuum flat-plate heat collector

A flat-plate collector and collector technology, applied in the field of solar energy applications, can solve the problems of inability to integrate the building, affecting the service life, and high cost of the half-box body, achieving good vacuum insulation effect, prolonging service life, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

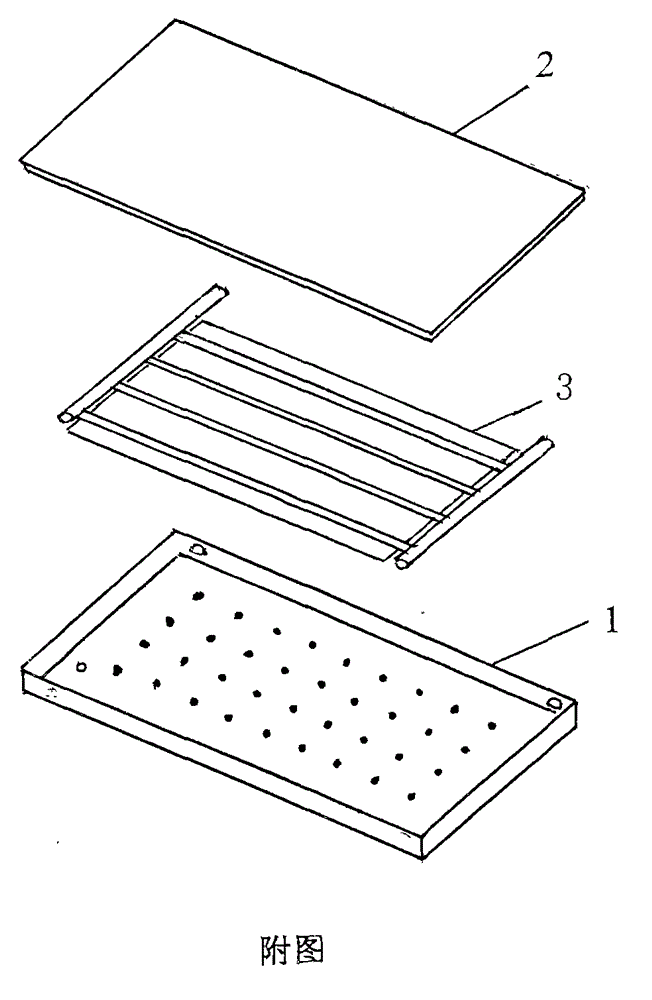

[0007] The specific implementation of the present invention will be described below in conjunction with the drawings. First, select the board core (3). The board core has a variety of structures. There are four nozzles, two nozzles, and both nozzles are on the board. Choose the same corner of the core according to your needs, and then make a mold according to the shape and size of the core, and press the hot melt glass into a glass half box body (1) and a glass cover plate (2) with homogeneous supporting columns , The glass half box body (1) has a pipe hole and a suction hole. The position of the suction hole is at the bottom of the half box, or on the side or the cover. The number and position of the pipe holes are the same as the nozzles on the core (3). Correspondingly, place the plate core (3) between the upper and lower support columns of the glass box body, so that the copper tube extends out of the tube hole to become a nozzle. The gap between the tube hole and the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com