Slugging cleaning device of silicon steel furnace and application thereof

A technology for cleaning equipment and silicon steel, applied in descaling equipment, furnaces, furnace components, etc., can solve the problems of great influence on continuous production, and achieve the effect of satisfying continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

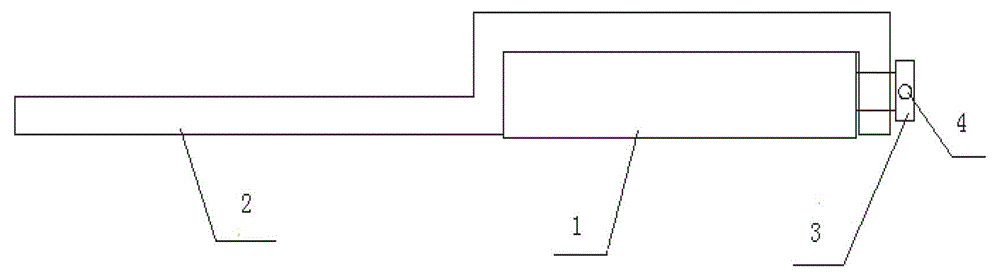

[0013] Such as figure 1 As shown, a silicon steel furnace slag cleaning device is composed of a steel plate 1, a slag removal rod 2, a locking bolt 3 and a crowbar 4. The steel plate 1 is a large steel plate with a thickness of 230 mm, a width of 1150 mm, and a length of 9000 mm. One end of the slag removal rod 2 is straight, the other end is hook-shaped, and there are locking holes and locking bolts 3 at the tail. The slag removal rod 2 is installed on the On the steel plate 1, the effect of the slag removal rod 2 is to clean it up by bumping the slag on the water beam in the heating furnace. On the cap of locking bolt 3, have circular hole, insert prying roller 4 in circular hole, crowbar 4 is that a diameter is 30 millimeters steel pipes or steel bar.

[0014] An application of a silicon steel furnace slag cleaning device, the application method is as follows:

[0015] Put the silicon steel slag cleaning device on the roller table on the tapping side of the heating furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com