Method for preparing lithium ferrous phosphate nanoparticles by template induction method

A technology of lithium ferrous phosphate and nanoparticles, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of no substantial improvement in material conductivity and large-magnification output performance, large particle agglomeration or sintering, and Increase the diffusion distance of lithium ions and other issues to achieve the effects of easy access, crystallization degree and small agglomeration, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Pretreatment of silicon wafers: The bulk silicon wafers cut into 1cm×1cm×0.5mm were ultrasonically cleaned in acetone and ultrapure water for 5 minutes, then soaked in Piranha solution at 60°C for 30 minutes, and the silicon wafers were taken out with ultrapure water Rinse with water, then blow dry with nitrogen to obtain a hydroxylated silicon-based substrate;

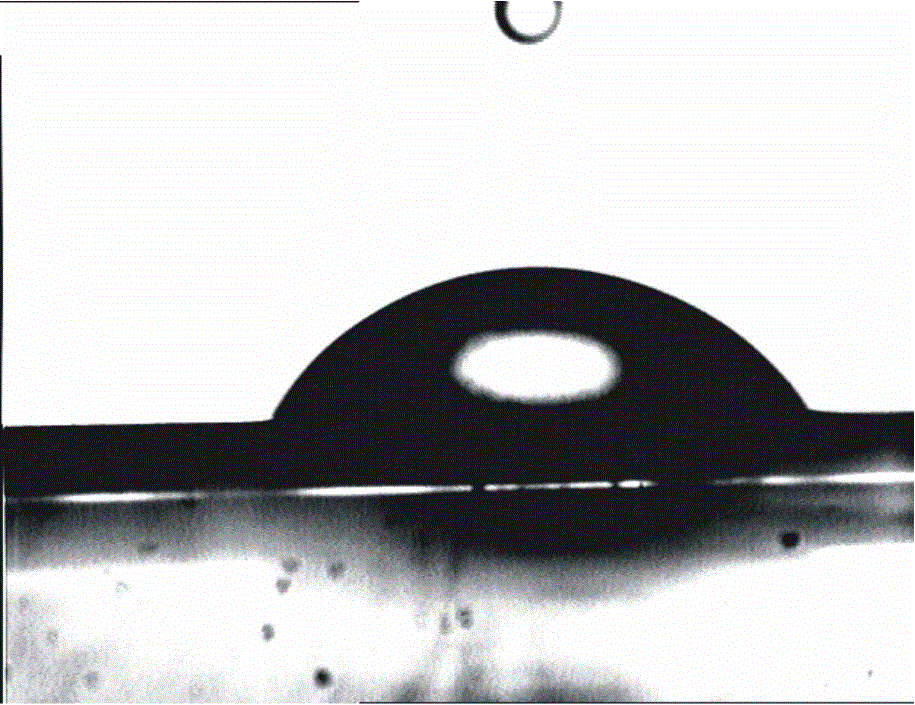

[0041]Preparation of 3-aminopropyl-trimethoxysilane (APTMS) thin film template: put the hydroxylated silicon-based substrate obtained through the above steps into an ethanol solution with a volume concentration of 0.2% APTMS for 1 hour for self-assembly, take out Afterwards, rinse with ethanol and ultrapure water in turn, and then blow dry with nitrogen to obtain the APTMS self-assembled film;

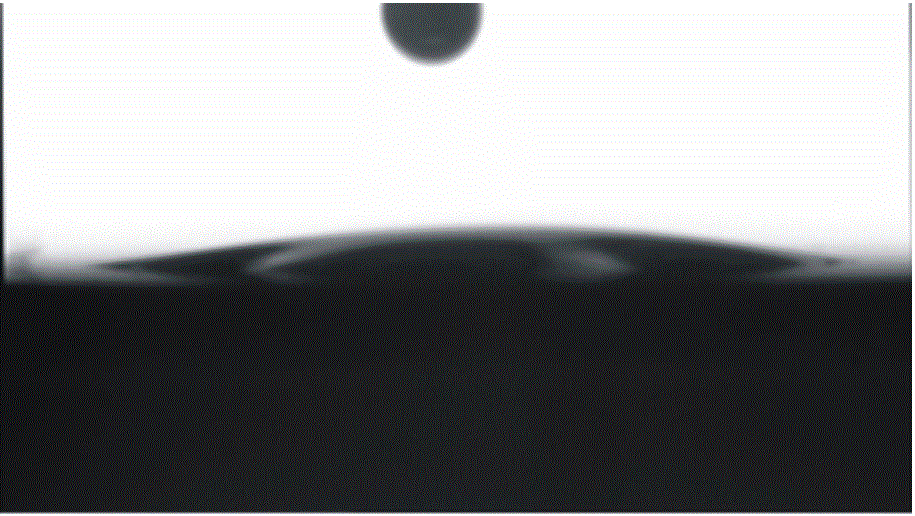

[0042] attached figure 1 It is the contact angle diagram of the hydroxylated silicon-based substrate prepared in Example 1. The water drop is almost completely spread out, and the contact angle is very small.

[0043]...

Embodiment 2

[0047] 1) Pretreatment of silicon wafers: The silicon wafers cut into 2cm×2cm×0.5mm were ultrasonically cleaned in acetone and ultrapure water for 15 minutes, then soaked in Piranha solution at 100°C for 60 minutes, and the silicon wafers were taken out with ultrapure Rinse with water, then blow dry with nitrogen to obtain a hydroxylated silicon-based substrate;

[0048] 2) Preparation of 3-aminopropyl-trimethoxysilane (APTMS) film template: soak the hydroxylated silicon-based substrate obtained in step 1) in 2% (volume fraction) APTMS ethanol solution for 1-2 Self-assembled within 1 hour, rinsed with ethanol and ultrapure water in turn after taking it out, and then dried with nitrogen to obtain the APTMS self-assembled film;

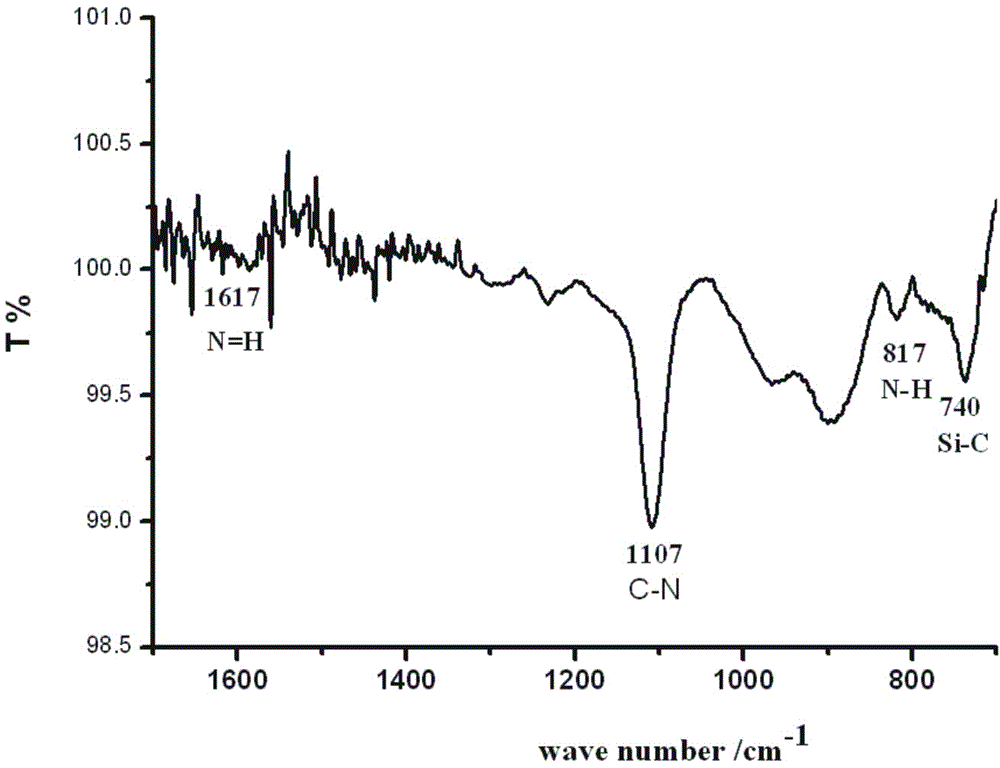

[0049] 3) In-situ phosphorylation of amino groups on the surface of the APTMS self-assembled film: The APTMS self-assembled film obtained in step 2) was immersed in an acetonitrile solution containing phosphorus oxychloride and 2,3,5-collidine, in which...

Embodiment 3

[0054] The method for preparing lithium iron phosphate nanoparticles by template induction method comprises the following steps:

[0055] 1) Pretreatment of silicon wafers: ultrasonically clean silicon wafers with a size of 1cm×1cm×0.5mm in acetone and ultrapure water for 10 minutes, then soak them in Piranha solution at 80°C for 45 minutes, take out the silicon wafers with ultrapure Rinse with water, then blow dry with nitrogen to obtain a hydroxylated silicon-based substrate;

[0056] 2) Preparation of 3-aminopropyl-trimethoxysilane (APTMS) film template: soak the hydroxylated silicon-based substrate obtained in step 1) in 0.5% (volume fraction) APTMS ethanol solution for 1.5 hours Self-assembled, rinsed with ethanol and ultrapure water in turn after taking it out, and then dried with nitrogen to obtain the APTMS self-assembled film;

[0057] 3) In-situ phosphorylation of amino groups on the surface of the APTMS self-assembled film: The APTMS self-assembled film obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com