A kind of high-order tangential enveloping grinding and polishing processing method and its application

A processing method and grinding and polishing technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problem of high frequency of grinding and polishing force measurement and feedback changes, relatively high requirements for the control system of grinding and polishing devices, and workpiece grinding and polishing. Poor surface smoothness and other problems, to achieve the effect of good surface accuracy and surface consistency, ensure accuracy and precision, and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

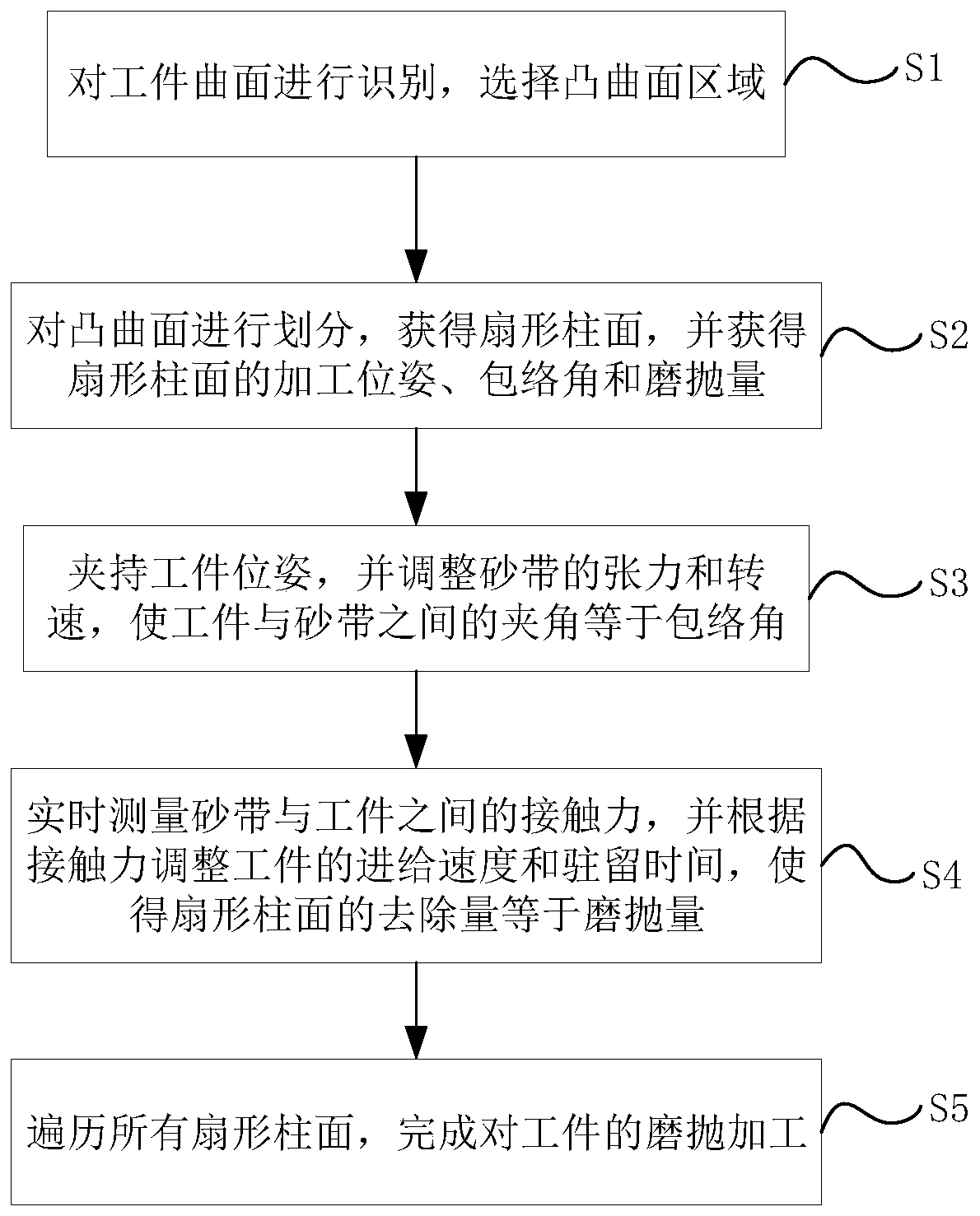

[0107] (1) Identify the convex surface on the surface of the workpiece, and after dividing the convex surface, select a fan-shaped cylinder (S S,i ).

[0108] (2) Obtain information such as the envelope angle, radius, and length of the bus bar of the fan-shaped cylinder, adjust the workpiece pose, adjust a fan-shaped cylinder in the workpiece to the corresponding processing posture of the fan-shaped cylinder, and make the abrasive belt and The fan-shaped cylinder contact surface is tangent;

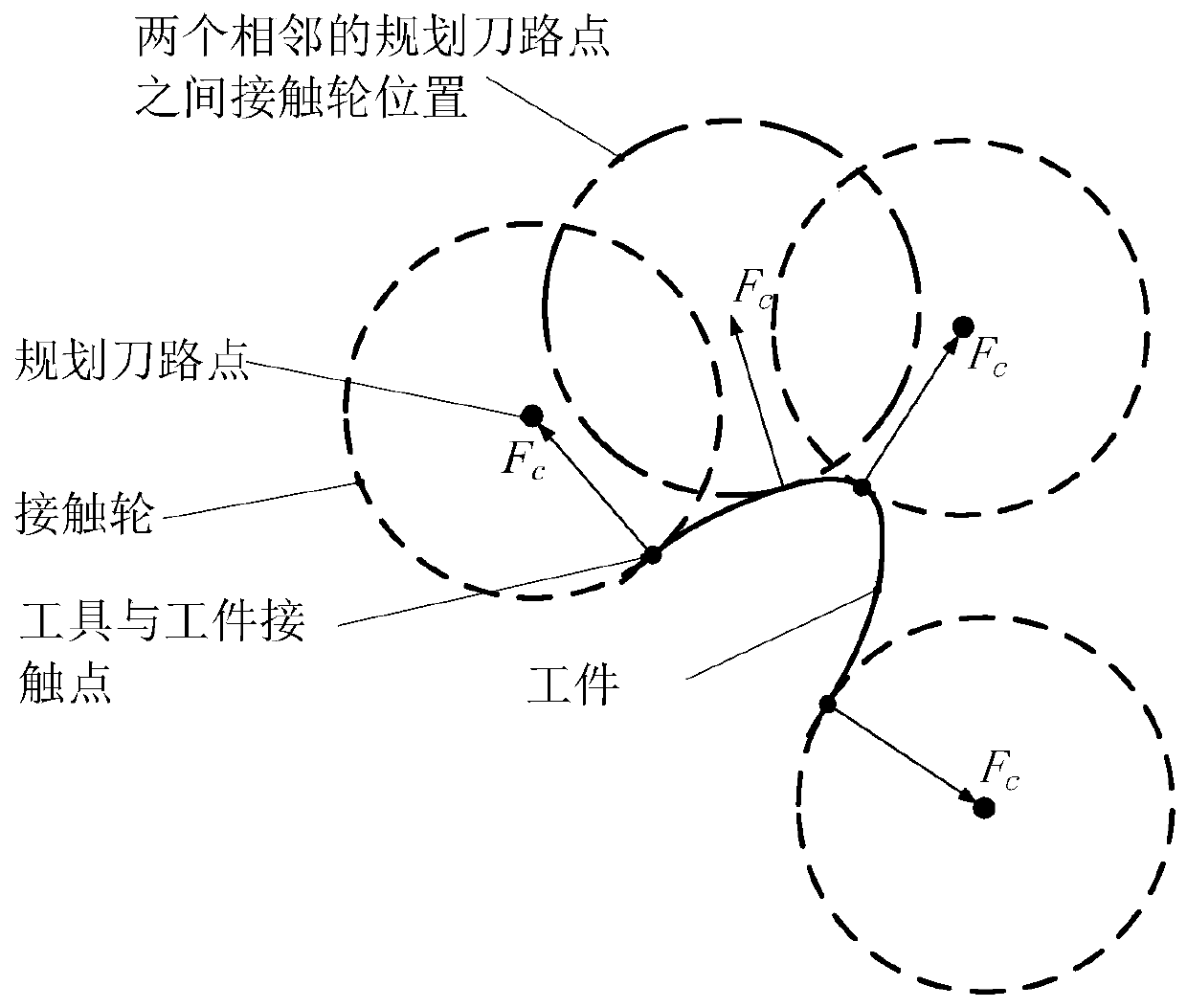

[0109] (3) The manipulator clamps the workpiece and keeps the processing posture corresponding to the fan-shaped cylinder and continues to move forward until the two guide wheels for tensioning the abrasive belt and the fan-shaped cylinder meet the following positional relationship, forming a desired envelope, as Figure 9 Shown:

[0110]

[0111] (4) During the entire grinding and polishing process, according to the set expectation, the abrasive belt is tensioned or relaxed to ensur...

Embodiment 2

[0118] (1) Identify the convex surface on the surface of the workpiece, and after dividing the convex surface, select a fan-shaped cylinder (S S,i ).

[0119] (2) Obtain information such as the envelope angle, radius, and length of the bus bar of the fan-shaped cylinder, and adjust the workpiece pose so that the angle bisector of the envelope angle coincides with the perpendicular line of the line connecting the centers of the two guide wheels, such as Figure 10 shown.

[0120] (3) The workpiece is fed along the perpendicular line connecting the centers of the two guide wheels to form a desired envelope.

[0121] (4) During the entire grinding and polishing process, according to the set expectation, the abrasive belt is tensioned or relaxed to ensure that the normal positive pressure of the abrasive belt-coated area remains within a relatively stable range.

[0122] (5) According to the set expected value, adjust the linear speed of the abrasive belt to keep it within a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com