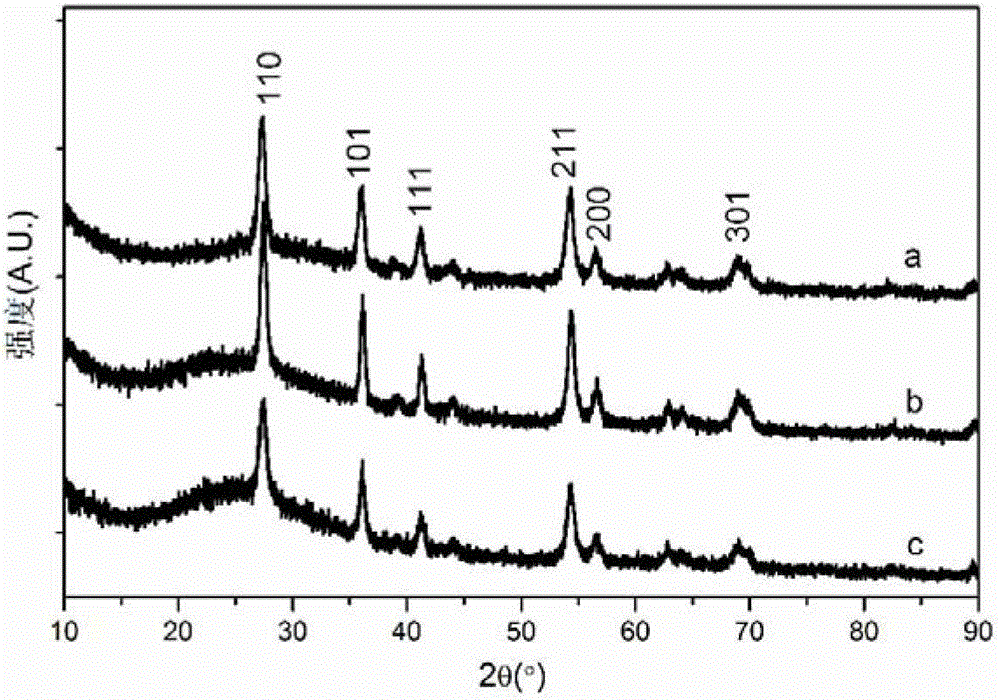

Titanium dioxide nano particle anode material of lithium ion power battery and method for preparing titanium dioxide nano particle anode material

A power battery, titanium dioxide technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of increasing lithium ion diffusion distance, material conductivity and high-rate output performance without substantial improvement, and industrialization difficulties. Improve specific capacity and cycle performance, excellent rate performance and cycle performance, crystallization degree and smaller effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] In order to better understand the present invention, the following examples are used to further illustrate the content of the present invention. The present invention is not limited to the following examples.

[0039] The microwave hydrothermal reaction device used in the present invention is Discover S-class produced by CEM Company.

[0040] Isopropyl titanate used in the following examples was produced by Sigma Aldrich, and hydrochloric acid, cetyl ammonium bromide, and ethylene glycol were produced by Sinopharm Chemical Reagent Co., Ltd., all of which were of analytical grade. The resistivity of the deionized water used in the experiment is not lower than 18MΩ·cm.

Embodiment 1

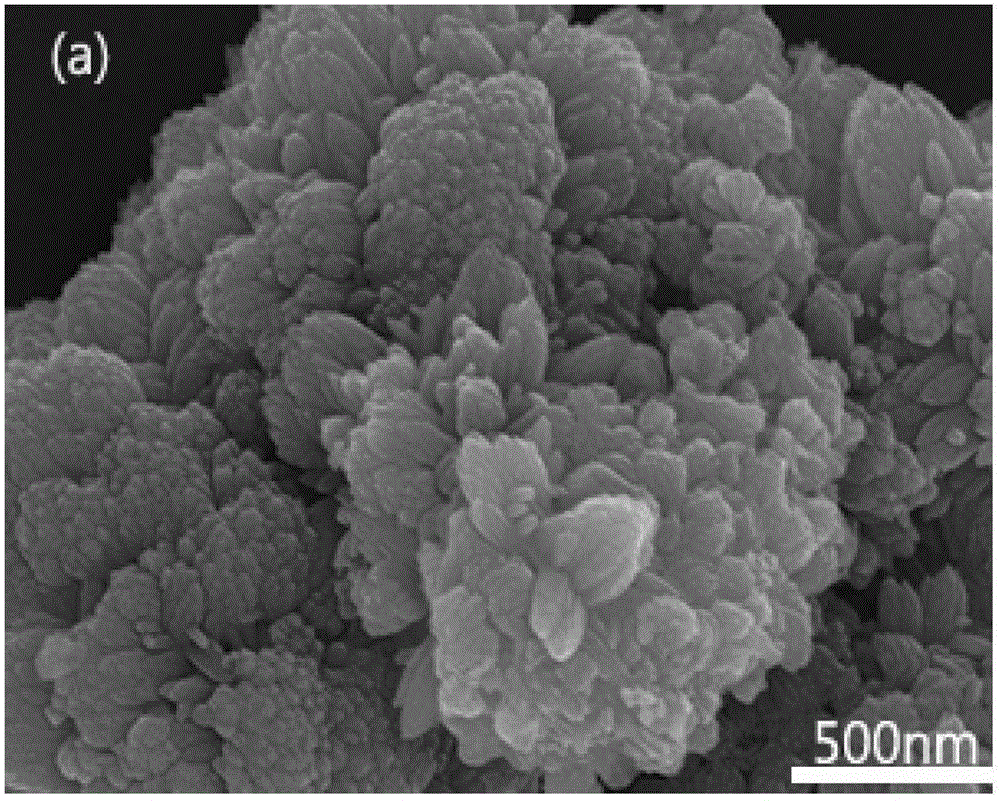

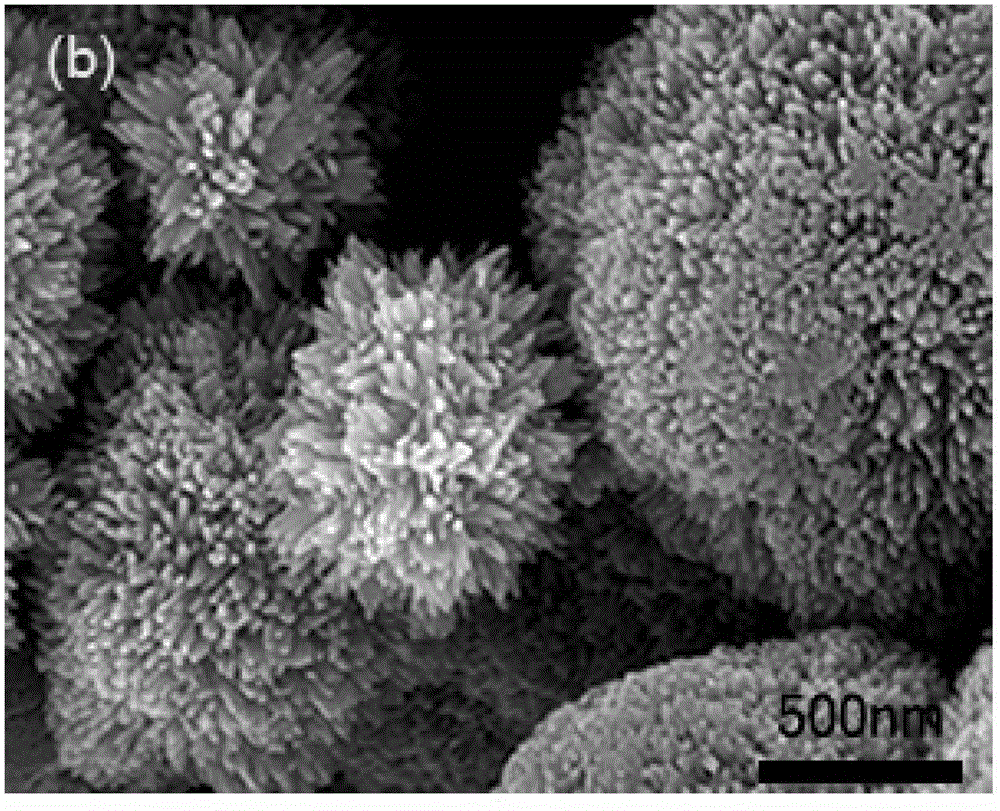

[0042] A titanium dioxide nano particle negative electrode material for a lithium ion power battery, which is prepared according to the following steps:

[0043]1) Preparation of precursor solution: Prepare raw materials according to the molar ratio of isopropyl titanate, cetyl ammonium bromide, hydrogen chloride and deionized water: 0.05:0.03:7:100, drop isopropyl titanate into the hydrochloric acid solution, and stirred for 30 minutes, which is solution A; add hexadecyl ammonium bromide to deionized water, and stir for 30 minutes until it dissolves to obtain a clear solution, which is solution B; mix solutions A and B and stir for 1 hour, Obtain a uniform and clear mixed solution; then mix and stir for 30 minutes according to the volume ratio of the mixed solution and ethylene glycol to obtain a precursor solution;

[0044] 2) Place the precursor solution in a microwave hydrothermal reaction device, set the upper limit of the reaction temperature to 140°C, the reaction power...

Embodiment 2

[0048] A titanium dioxide nano particle negative electrode material for a lithium ion power battery, which is prepared according to the following steps:

[0049] 1) Preparation of precursor solution: Prepare raw materials according to the molar ratio of isopropyl titanate, cetyl ammonium bromide, hydrogen chloride and deionized water: 0.05:0.03:7:100, drop isopropyl titanate into the hydrochloric acid solution, and stirred for 30 minutes, which is solution A; add hexadecyl ammonium bromide to deionized water, and stir for 30 minutes until it dissolves to obtain a clear solution, which is solution B; mix solutions A and B and stir for 1 hour, Obtain a uniform and clear mixed solution; then mix and stir for 30 minutes according to the volume ratio of the mixed solution and ethylene glycol to obtain a precursor solution;

[0050] 2) Place the precursor solution in a microwave hydrothermal reaction device, set the upper limit of the reaction temperature to 140°C, the reaction powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com