Hypotensive compound preparation and preparation method thereof

A compound, blood pressure lowering technology, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

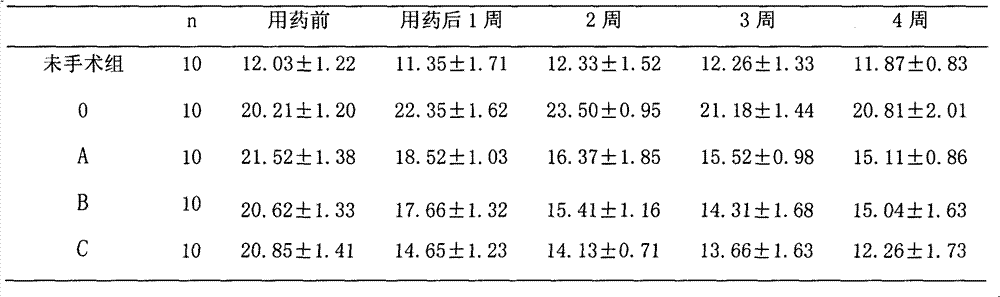

Image

Examples

Embodiment 1

[0008] Embodiment 1: tablet

[0009] Name of raw material

Dosage

Temopril Hydrochloride

2g

Olmesartan medoxomil

20g

45g

36g

Sodium carboxymethyl cellulose

10g

55g

1.6g

Appropriate amount

Co-made

1000 pieces

[0010] Note: Temopril hydrochloride is calculated as Temopril

[0011] Process: Take each raw material, crush it through a 100-mesh sieve, and set aside; pass each auxiliary material through a 60-mesh sieve, and set aside; except magnesium stearate, take each raw and auxiliary material separately, put them in a high-speed mixing granulator and mix them evenly. Add an appropriate amount of water-based soft material, granulate at 24 mesh, dry in a fluidized bed at 50 degrees, granulate at 24 mesh, add magnesium stearate, mix evenly, press into tablets...

Embodiment 2

[0012] Example 2: chewable tablet

[0013] Name of raw material

Dosage

Temopril Hydrochloride

4g

Olmesartan medoxomil

20g

160g

105g

Sodium carboxymethyl cellulose

10g

5g

essence

Appropriate amount

Magnesium stearate

1.6g

Appropriate amount

Co-made

1000 pieces

[0014] Note: Temopril hydrochloride is calculated as Temopril

[0015] Process: take each raw material and auxiliary material, and crush them through a 100-mesh sieve, and set aside; except for magnesium stearate, take each raw material and auxiliary material separately, mix them evenly in a high-speed mixing granulator, add an appropriate amount of water to make a soft material, 24 mesh Granulate, dry in a fluidized bed at 50 degrees, granulate into 24 meshes, add magnesium stearate, mix evenly, and compress into tablets.

Embodiment 3

[0016] Example 3 Capsules

[0017] Name of raw material

[0018] Process: Take the above-mentioned raw materials, grind them through 80-mesh sieves respectively, and set aside; each auxiliary material respectively pass through 60-mesh sieves, and set aside; except magnesium stearate, take each raw and auxiliary materials respectively, mix them evenly according to the method of equal increase, and add an appropriate amount of Water-based soft material, granulated with 18 mesh, dried in a fluidized bed at 60 degrees, granulated with 24 mesh, added with magnesium stearate, mixed evenly, filled into empty capsule shells, and obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com