Driving device for rear hub of bicycle

A driving device and bicycle technology, which is applied to axles, wheels, hubs, etc., can solve the problems of low hub applicability, insufficient sensitivity, and increased inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to have a further understanding and understanding of the purpose, features and effects of the present invention, please cooperate with [Description of Drawings] below, and describe in detail as follows:

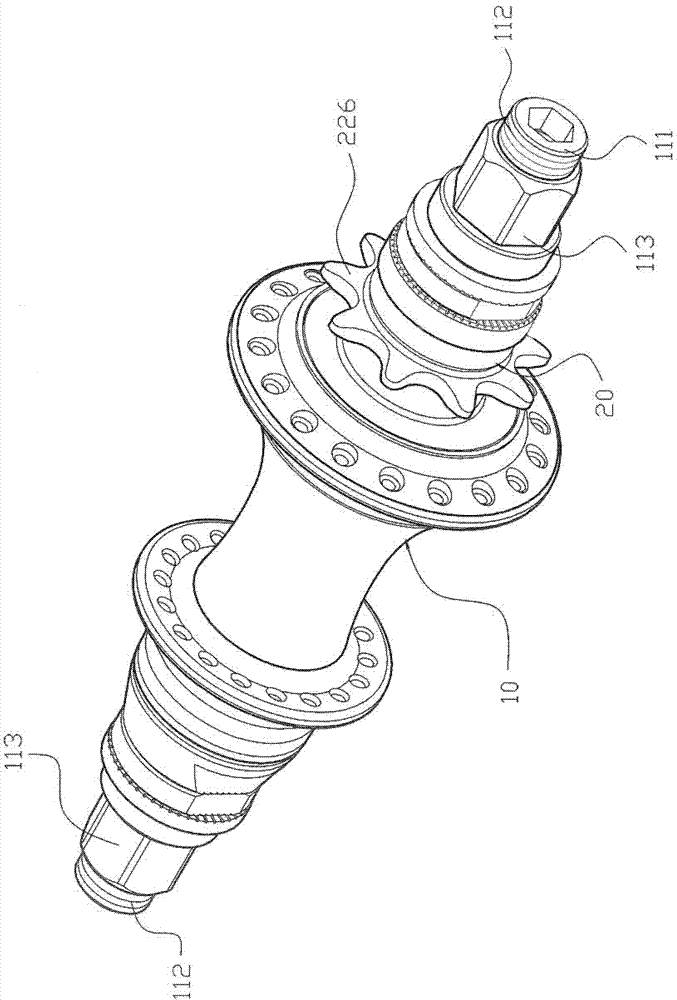

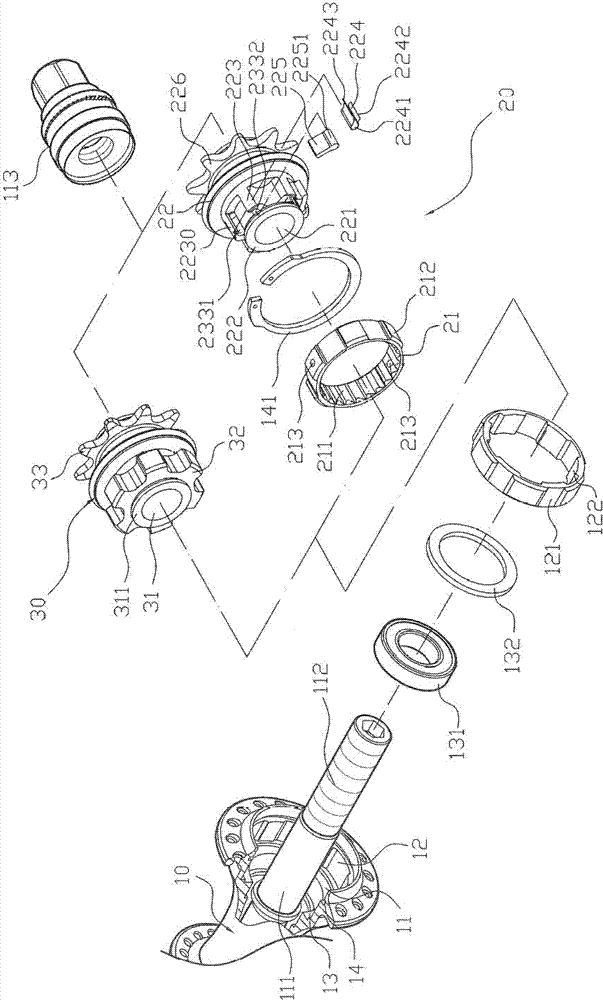

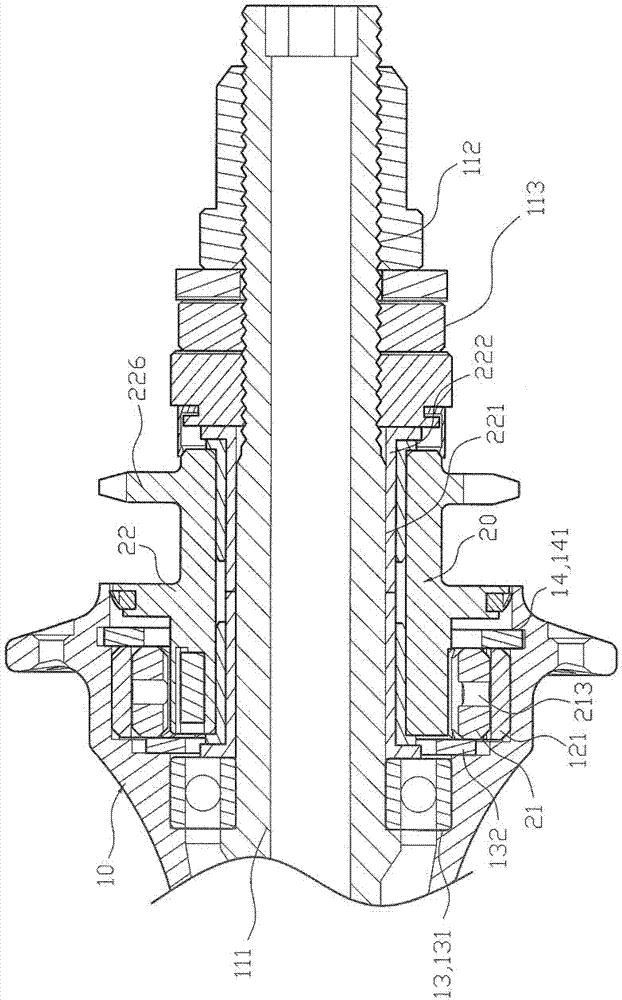

[0068] First of all, please start by figure 1 and figure 2 As shown, a driving device for a rear hub of a bicycle includes: a hub shell 10, a one-way drive assembly 20 and a two-way drive seat 30, wherein the hub shell 10 has a housing on one side Space 11, accommodating space 11 and having a mandrel 111 through the pivot, mandrel 111 is provided with a threaded section 112 at one end, threaded section 112 is provided with a locking member 113 to lock, and this accommodating space 11 is set in the inner periphery ring There are a plurality of fitting grooves 12, and the fitting grooves 12 are embedded with a fixed ring 121 in a tightly fitting manner. The fixed ring 121 is made of steel material, thereby increasing the structural strength of the hub shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com