Automatic coal blending system

A coal blending system and weighing technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low efficiency and high labor cost of workers, and achieve the effect of reducing labor intensity and realizing large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

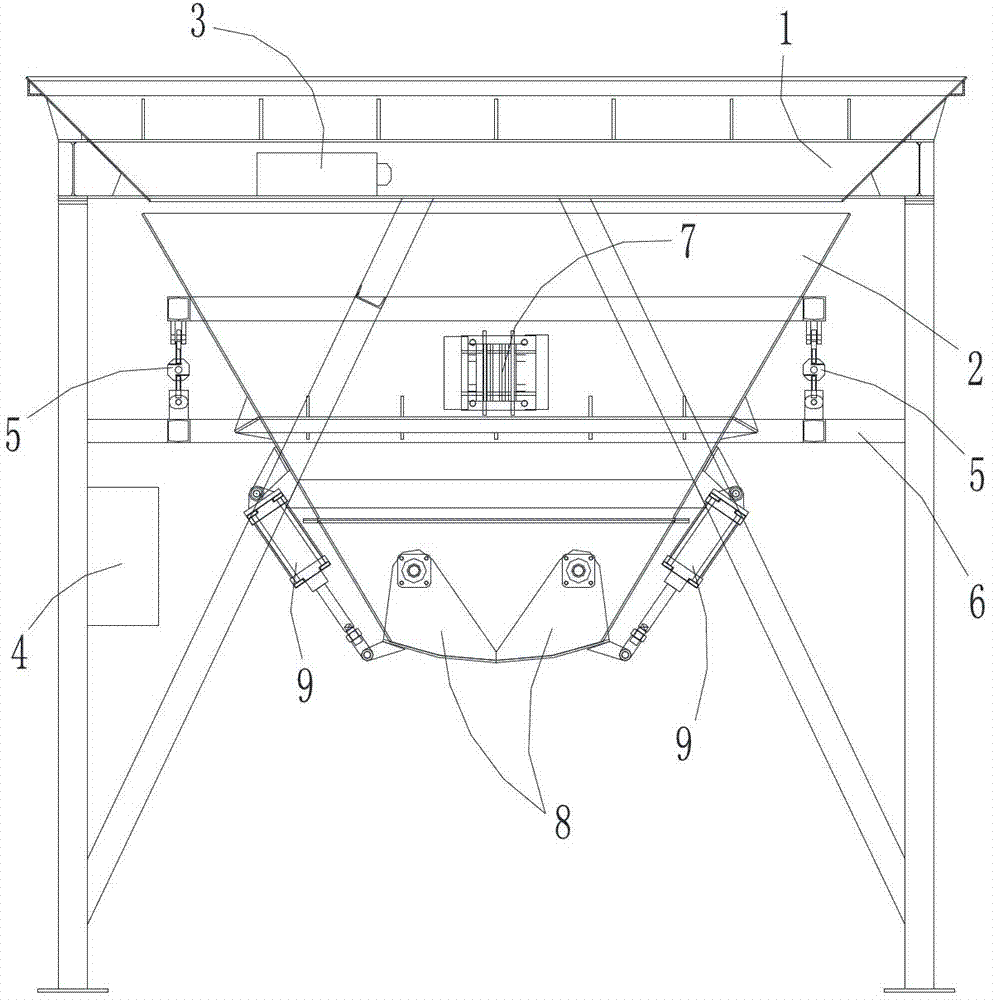

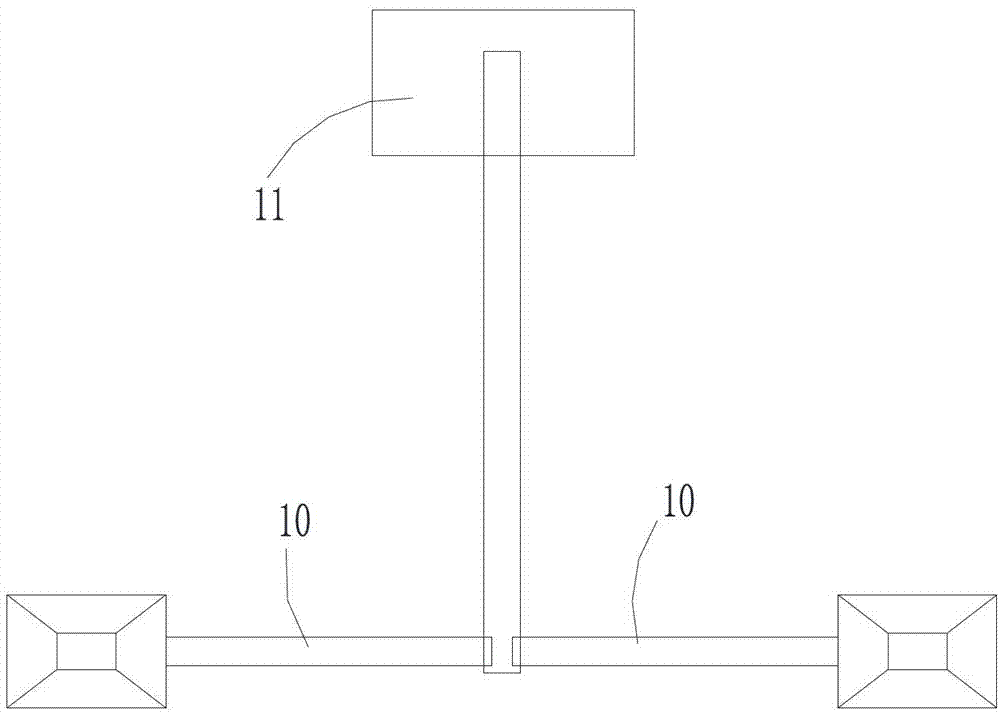

[0015] as attached figure 1 and attached figure 2 As shown, the coal blending system of the present invention is used to mix the first type of coal with different combustion points and the second type of coal into the mixed coal of the required combustion point according to the preset ratio, including a weighing unit and a mixing unit And the control unit 4, the weighing unit includes two weighing mechanisms for weighing the first kind of coal and the second kind of coal respectively, and the mixing unit includes a mixing container 11 for mixing the first kind of coal and the second kind of coal And two transmission mechanisms that transport the first coal and the second coal to the mixing container 11 respectively, the weighing mechanism includes a hopper 1 for holding the first coal or the second coal, and a hopper for measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com