Preparation method of nano silicon dioxide

A technology of nano-silica and silicon dioxide, which is applied in the preparation of nano-silicon dioxide and the preparation of inorganic nano-materials, can solve the problems of high cost, difficult recycling, environmental pollution, etc., and achieve uniform particle size, low-cost raw materials, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 54.6mg alanine (6.1×10 -4 mol) was dissolved in 41.4 g of distilled water (2.3 mol), 3.13 g of tetraethyl orthosilicate (0.015 mol) was added, and the whole reaction system was stirred at 50-60° C. for 24 hours to obtain a suspension of silica seed crystals.

[0033]The temperature of the system is controlled by a constant temperature tank at 25°C, and 2ml of the suspension is measured, and distilled water is added to 44ml (the amount of the substance is 2.44mol), that is, it is diluted 22 times. 2.96g triblock polymer P123 (molar mass 5800g / mol, substance amount 5.1×10 -4 mol), stirred for 20min to dissolve it completely, then added 6.24g of sodium silicate nonahydrate (equivalent to 0.022mol of sodium silicate), and stirred vigorously for 30min to form a homogeneous solution.

[0034] Keep stirring, and add 50wt% sulfuric acid dropwise to the homogeneous solution at 20-30° C. until the pH of the solution is 7 to form a silica gel. The obtained silica gel was aged in...

Embodiment 2

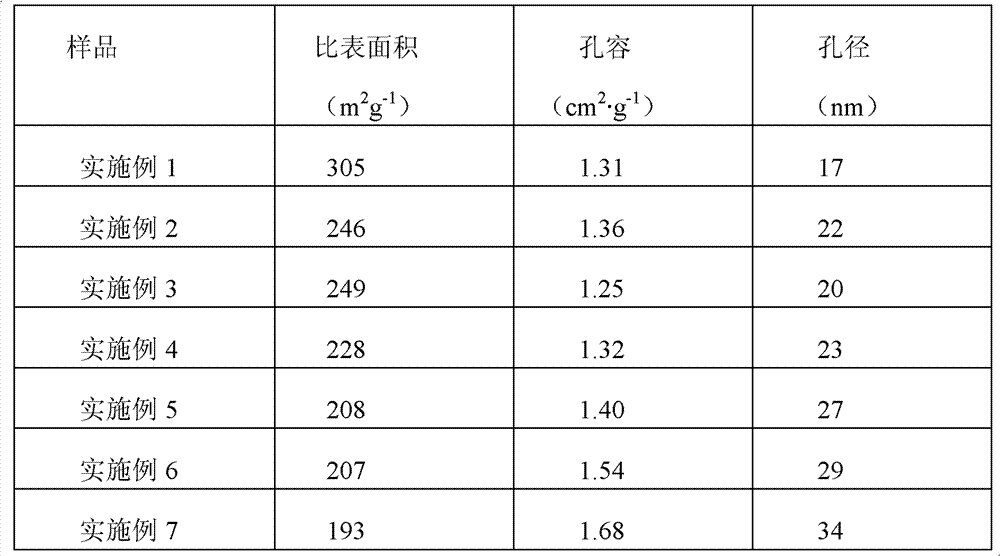

[0036] The mass of triblock polymer P123 added in the reaction system is 1.48g (2.55×10 -4 mol), all the other steps are the same as the method described in Example 1. The specific surface area and pore structure data of the samples are listed in Table 1.

Embodiment 3

[0038] 54.6 mg of alanine was dissolved in 41.4 g of distilled water, 3.13 g of ethyl orthosilicate was added, and the whole reaction system was stirred at 50-60°C for 24 hours to obtain a suspension of silica seed crystals.

[0039] The temperature of the system is controlled by a constant temperature tank at 25°C, and 2ml of the suspension is measured and diluted 22 times with distilled water. Add 0.093g cetyltrimethylammonium bromide (2.6×10 -4 mol), stirred for 20min to dissolve it completely, then added 6.24g of sodium silicate, stirred vigorously for 30min to form a homogeneous solution. Keep stirring, and add 50 wt% sulfuric acid drop by drop until the pH of the solution is 7 to form a silica gel. The obtained silica gel was aged in a sealed environment for 18 hours, and the aging temperature was 25°C. The aged gel is filtered, washed and dried, and then calcined at 550°C to obtain the product. The specific surface area and pore structure data of the samples are list...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap