Noctilucent floor board processing technology

A processing technology and floor technology, applied in luminescent materials, floors, chemical instruments and methods, etc., can solve problems such as the inability to actually mass-produce ordinary applications, the loss of luminous efficacy of the crystal structure, and the inability to use in large areas. Long-term effective luminous performance, improved aesthetics and texture, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

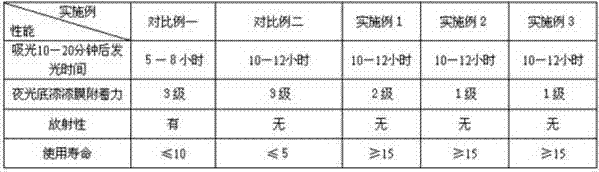

Examples

Embodiment 1

[0047] A luminous floor processing technology, characterized in that: comprising the following steps:

[0048] (1) Making floor slabs;

[0049] (2) Applying a luminous primer to the floor slab prepared in step (1) to obtain a floor slab one;

[0050] (3) Apply an elastic primer, a wear-resistant primer and a hardened primer to the first floor slab obtained in step (2) to obtain a second floor slab;

[0051] (4) Apply 2-5 coats of topcoat to the second floor slab prepared in step (3) to obtain a luminous floor.

[0052] After each painting process, drying treatment is required, and sanding treatment is required after part of the drying treatment process. The detailed steps are as follows:

[0053] Floor slab-luminous primer-infrared drying-sanding-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding-wear-resistant bottom Paint-infrared drying-sanding-infrared drying-sanding-finish-infrared drying-sanding-finis...

Embodiment 2

[0060] The difference from the above-mentioned embodiment lies in the ratio of each component, this embodiment uses multi-layer solid wood composite floor slabs.

[0061] The detailed steps are as follows:

[0062] Floor slab-light primer-luminous primer-infrared drying-sanding-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding Light - wear-resistant primer - infrared drying - sanding - infrared drying - sanding - topcoat - infrared drying - sanding - topcoat - infrared drying - topcoat.

[0063] The luminous primer contains 30% luminous powder by weight; the thickness of the luminous primer is 200um; the particle size of the luminous powder is 1200 mesh. The anti-settling agent selected in this embodiment is a high-viscosity resin.

[0064] The composition weight ratio of red luminous powder is: barium sulfate 50%, magnesium sulfate 35%, zinc oxide 5%, lithium phosphate 5%, copper nitrate 5%, europium 3%, si...

Embodiment 3

[0067] The difference from the above embodiment is that the floor slab in this embodiment is a solid wood antique floor slab, and the step (1) includes making wood texture grooves on the floor slab, and only sanding the luminous primer when sanding The raised part of the wood grain is primed, and the primer of the grooved part of the wood grain is retained. The prepared floor glows at night in the grooved part of the wood grain, highlighting the wood grain of the whole floor in the form of light, which is very beautiful.

[0068] The detailed steps are as follows:

[0069] Floor slab-luminous primer-infrared drying-sanding-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding-wear-resistant bottom Paint - infrared drying - sanding - infrared drying - sanding - topcoat - infrared drying - sanding - topcoat - infrared drying - topcoat.

[0070] The luminous primer contains luminous powder in a weight ratio of 25%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com