Manual-automatic integrated tensioning system

A tensioning and manual technology, applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve the problems of extensive tensioning operations, low construction efficiency, large prestress loss, etc., to avoid emergencies and to have wide applicability. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

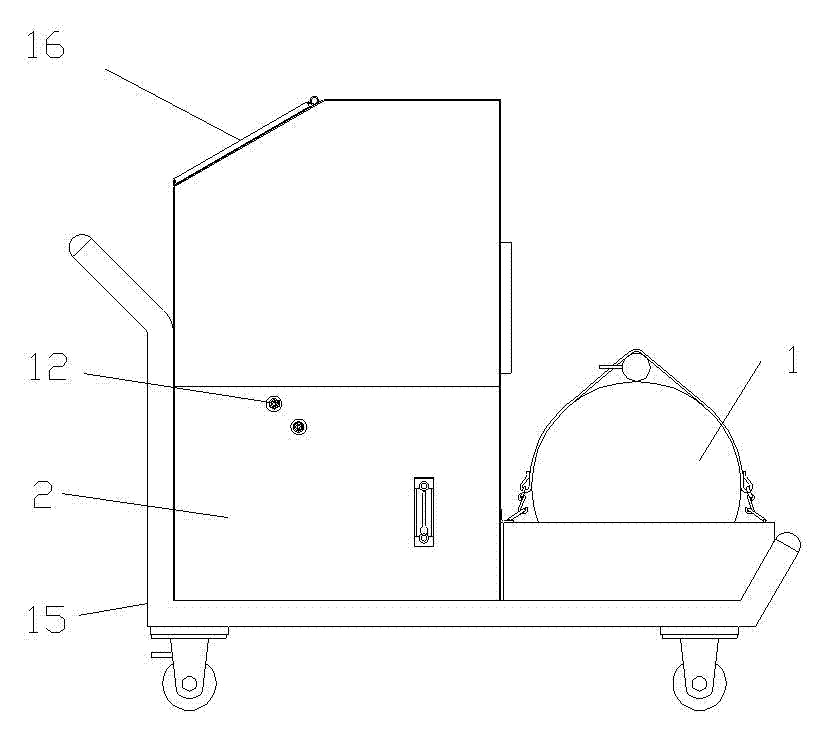

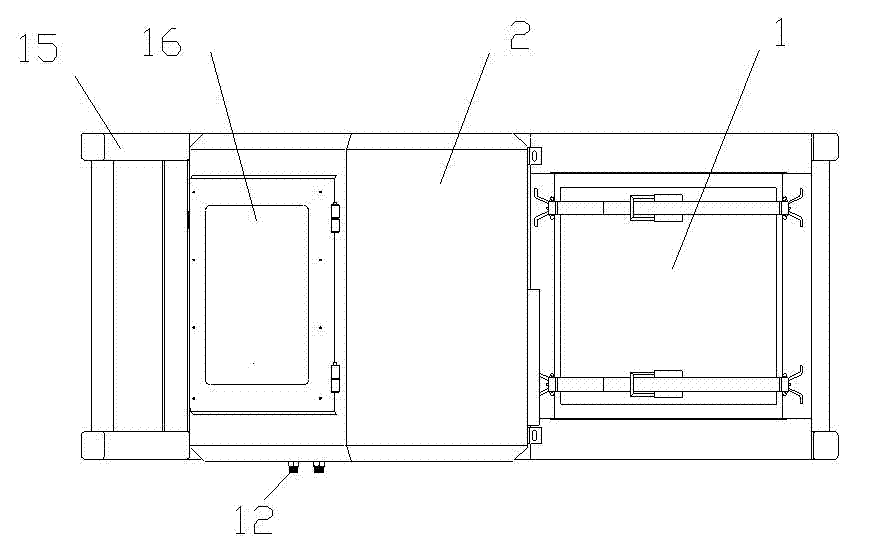

[0042] Such as figure 1 and figure 2 Shown is a schematic structural view of an embodiment of the manual-automatic integrated tensioning system of the present invention. The manual-automatic integrated tensioning system of this embodiment includes a hydraulic cylinder jack 1 , a hydraulic system for driving the action of the hydraulic cylinder jack 1 and a control box for controlling the action of the hydraulic cylinder jack 1 .

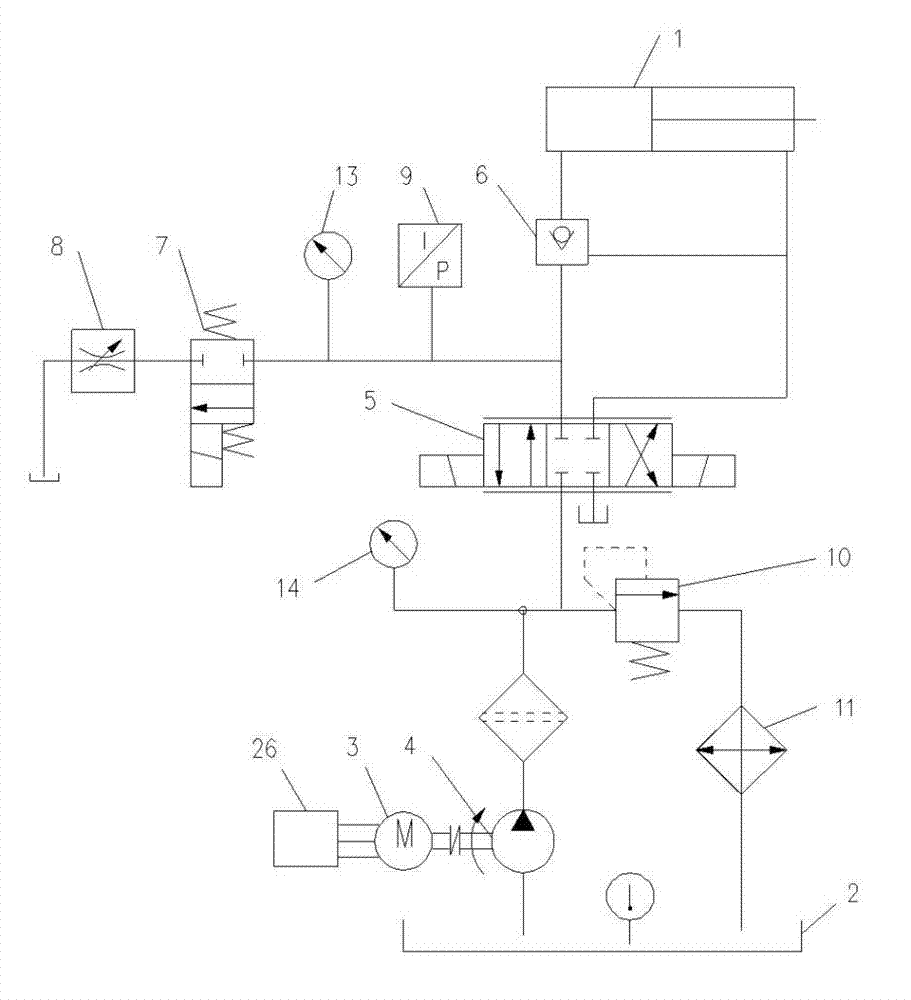

[0043] Such as image 3 As shown, the hydraulic system includes a fuel tank 2, a hydraulic pump 4, a motor 3, a frequency conversion control system and a servo proportional control system. The control system includes a servo proportional valve 5 arranged between the hydraulic pump 4 and the hydraulic cylinder jack 1 and used for fine-tuning the loading of the hydraulic cylinder jack 1. A hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com