Drill bit for particle percussion drilling

A particle impact and drill bit technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of poor drillability, inability to form efficient rock breaking, compaction and other problems, reduce drilling rig operation time, and achieve fast and efficient drilling operations. , The effect of increasing the ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

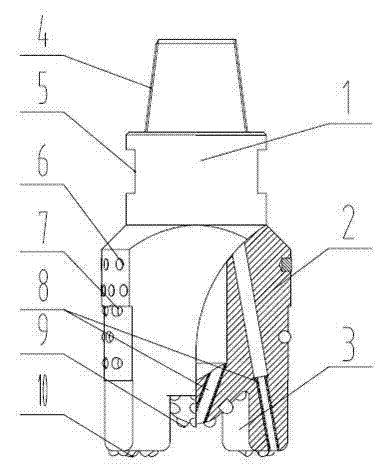

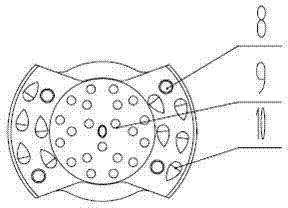

[0011] Refer to attached figure 1 with 2 , A drill bit for particle impact drilling, including a drill joint 1, a drill body 2, and a cutting head 3. The drill joint 1 has threads 4 and clamps 5, and the drill body 2 is inlaid with gauge teeth 6 and side cutters 7. The middle of the lower part of the cutting head 3 is a conical protrusion, and the outer edge of the lower part of the cutting head 3 is two sections of annular flanks symmetrical to the center; After the fan-shaped groove, cutting teeth 10 are inlaid on the two-section annular flanks on the lower outer edge of the cutting head 3; the nozzle 8 runs through the tapered protrusion in the middle of the lower part of the cutting head 3 and the two annular flanks on the lower outer edge of the cutting head 3. The outer diameter of the drill body 2 at the place where the gage teeth are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com