High-speed hydraulic drill

A hydraulic drilling rig, high-speed technology, applied in drill pipe, drill pipe, earth-moving drilling, etc., can solve problems such as affecting the operator's sight, flying dust, inconvenient installation and maintenance, etc., to achieve good technical and economic value, reduce swing amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

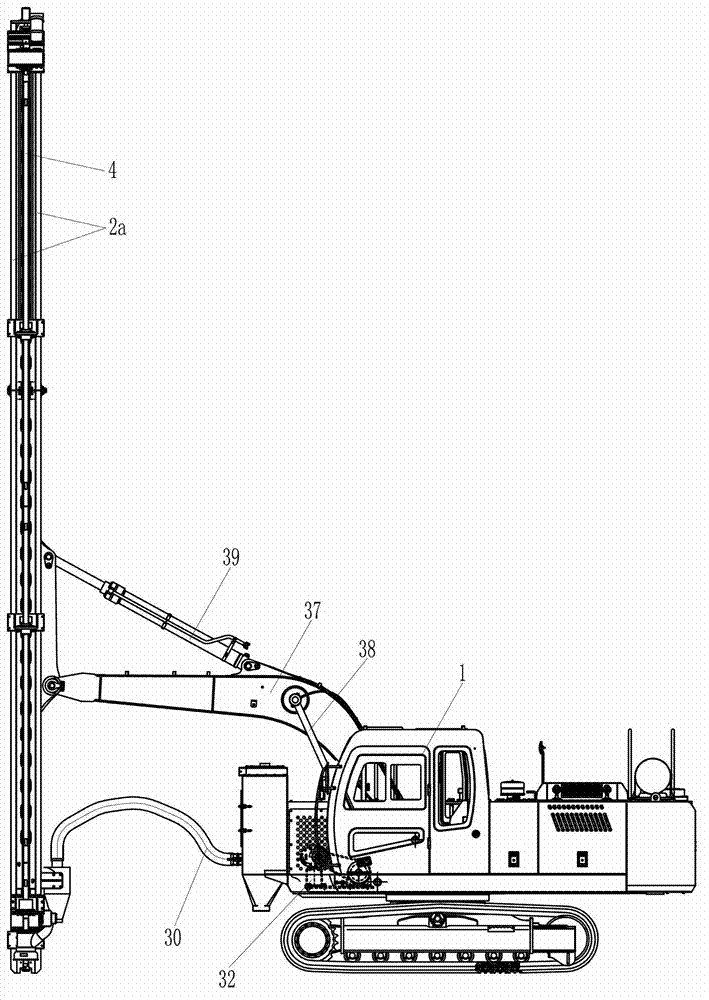

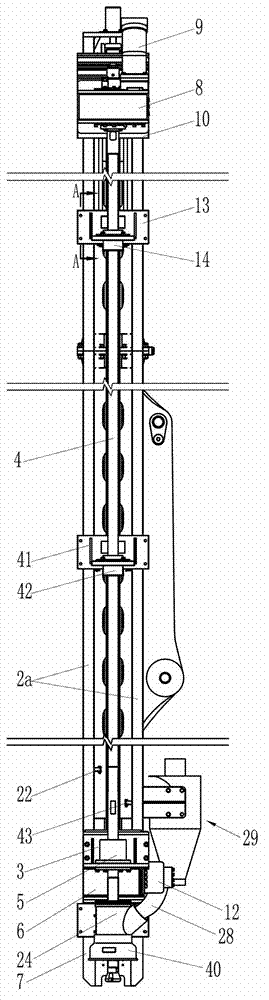

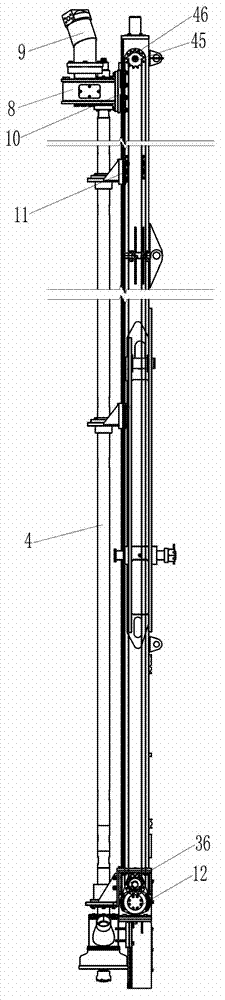

[0061] Such as Figures 1 to 11 As shown, the high-speed hydraulic drilling rig is mainly composed of a main engine 1, a drill arm 2, a positioning frame 3, a drill rod 4, a positioning sleeve 5, a box body 6, a mounting seat 7, a power box 8, a rotating motor 9, a carriage 10, and a chain 11 , lifting motor 12, guide frame 13, guide sleeve 14, guide frame follower mechanism, dust cover 24, mounting plate 25, connector 26, oil cylinder 27, first air pipe 28, primary dust collector 29, second air pipe 30 , secondary dust collector 31, screw air compressor 32, pinion 33, driving shaft 34, bull gear 35, driving sprocket 36, boom 37, boom cylinder 38, stick cylinder 39 and rubber sleeve 40 constitute. Wherein the host 1 basically adopts the existing structure, and the screw air compressor 32 is fixedly installed at the front of the host 1 .

[0062] Such as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com