Method and system for automatical antifreezing and thermal insulating of tunnel lining in high and cold areas

A technology of heat preservation system in alpine regions, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of high operation and maintenance costs, inability to eradicate tunnel freezing damage, consume more energy, etc., and achieve low operation and maintenance costs, production and installation costs Low cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

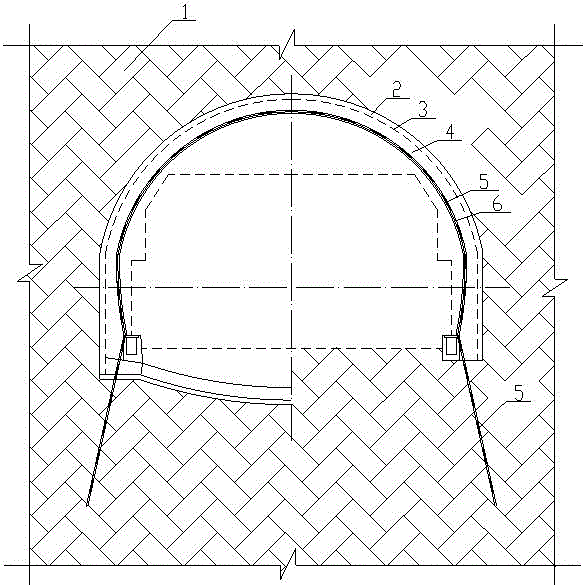

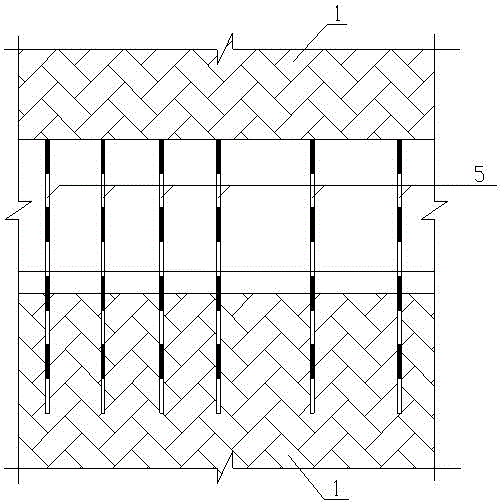

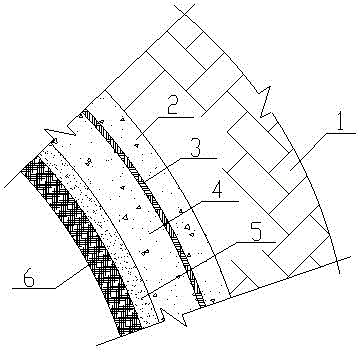

[0015] Such as Figure 1~3 As shown, an automatic antifreeze and thermal insulation system for tunnel lining in alpine regions, the tunnel is surrounded by surrounding rock 1, primary lining 2, waterproof board 3, secondary lining 4, and thermal insulation layer 6 from outside to inside. Between 4 and the thermal insulation layer 6, a number of heating pipes 5 are arranged at intervals along the length of the tunnel. The diameter, wall thickness and length of the heating pipes 5 can be designed according to the design requirements (tunnel cross-sectional size and local climate and hydrological conditions, etc.) Definitely, the spacing of the heating pipes 5 can be determined according to the design requirements, the lower parts of the two ends of the heating pipes 5 are buried in the surrounding rock 1 under the tunnel road surface, and the two ends of the heating pipes 5 are sealed with refrigerant. figure 1 Middle: The left half shows the tunnel with an inverted arch, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com