Seal structure of piston type spring brake chamber

A sealing structure and brake chamber technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of unsatisfactory sealing effect and dustproof effect, troublesome processing and assembly, complex structure, etc., to prevent The effect of gap extrusion, simplified structure and process, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

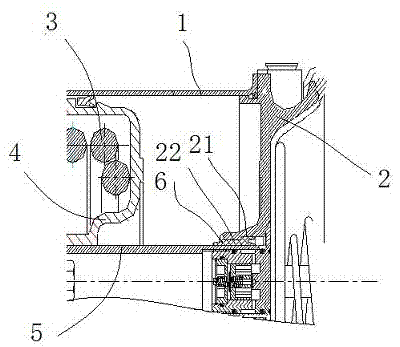

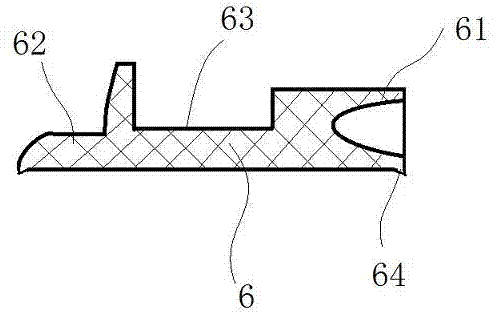

[0026] Embodiment 1: as figure 1 , 2 as shown, one A sealing structure of a piston-type spring brake chamber, including a cylinder body 1 and a middle body 2 forming a spring chamber, a spring 3 and a spring seat 4 are arranged in the spring chamber, and the spring seat 4 bears on the piston 5, and the piston 5 and the middle body 2 The middle part of the middle part is movable, and a step-shaped wide sealing groove 21 is provided at the joint between the piston 5 and the middle body 2. The middle part of the step-shaped wide sealing groove 21 is provided with an inwardly protruding shoulder 22, and the step-shaped wide sealing groove 21 is embedded with a matching sealing ring 6, and the sealing ring 6 is connected by a Y-shaped lip seal structure of the front end 61, a boot-shaped lip seal structure of the rear end 62, and a stepped 63 structure in the middle. In the composite sealing ring formed in one piece, the inner surface of the sealing ring 6 is a cylindrical stru...

Embodiment 2

[0030] Embodiment 2: The lip seal structure at the rear end of the seal ring is a J-shaped lip seal ring, the lip seal structure at the front end of the seal ring is a V-shaped lip seal ring, and the rest of the structure is the same as that in Embodiment 1; a single J In order to prevent it from falling off, the lip-shaped sealing ring of this type needs to be pressurized, and cannot be used for end face sealing or dustproof, while the composite sealing ring of the three-piece structure of the present invention can be used on the end face without pressing parts. Sealing and dustproofing, especially the dustproofing effect of the end face, is a long-standing and difficult problem for the prior art, which can be solved satisfactorily by applying the present invention.

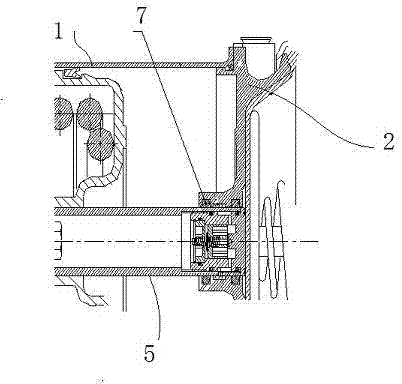

[0031] image 3 Shown is an installation structure diagram of a discrete seal ring in the prior art, and there are two O-shaped seal rings 7 at the front and rear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com