Integrated pneumatic shifting operation system

A technology for a pneumatic shifting and operating system, applied in the field of vehicle shifting systems, can solve the problems of high and low gear switching failure of transmission, complicated transmission structure, transmission cylinder air leakage, etc., and achieves simple and compact design structure, reduced production hours, and reduced The effect of cylinder blow-by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For ease of understanding, the preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

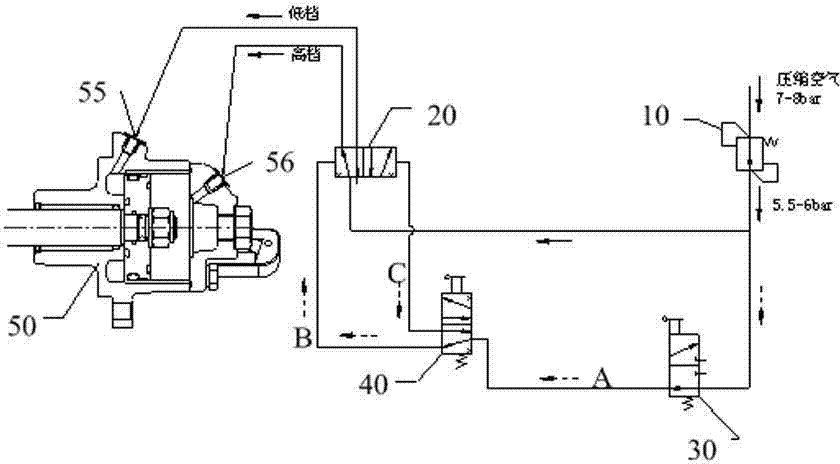

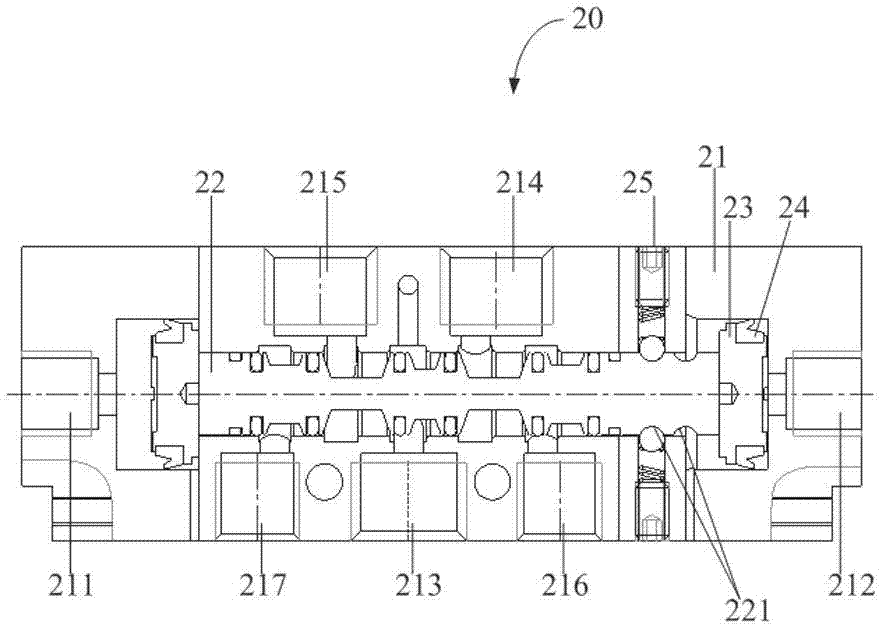

[0022] Please refer to figure 1 with figure 2 , A pneumatic shift control system for a vehicle, comprising: an air filter regulator 10, a dual-air-controlled single H valve 20, a pneumatic control valve 30, a handle valve 40 and a transmission cylinder 50, the connection relationship among them is:

[0023] The input end of the air filter regulator 10 is connected to the vehicle air source. The compressed air pressure at the input end of the air filter regulator 10 is 7-8 Bar, and the output pressure of the air filter regulator 10 is 5.5- 6Bar; in addition,

[0024] The output end of the air filter regulator 10 is respectively connected to the first input end 213 of the dual air control single H valve 20 and the input end of the air circuit control valve 30,

[0025] The output end of the gas path control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com