Controllable wedge pre-tightening mechanism for micro platform of compliant mechanism

A technology of micro-motion platform and compliant mechanism, which is applied in the direction of friction-clamped detachable fasteners, machine tables/brackets, connecting components, etc., and can solve the problems of small preload range, buckling of compliant hinges, and platforms exceeding the maximum stroke, etc. problems, to achieve the effect of convenient adjustment and maintenance, increase the preload range, and avoid blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments. Unless otherwise specified, the materials and processing methods used in the present invention are conventional materials and processing methods in the technical field.

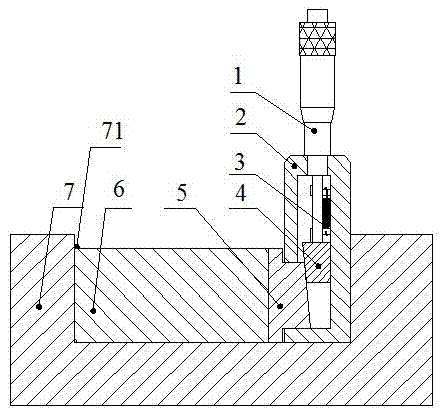

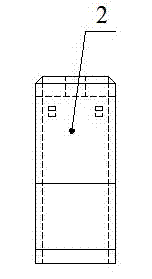

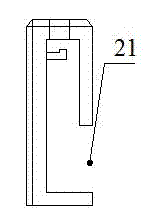

[0022] Such as figure 1 As shown, the controllable wedge pretension mechanism for the micro-motion platform of the compliance mechanism includes a micrometer 1, a base 2, a spring 3, a vertical wedge 4, a traverse wedge 5, a piezoelectric ceramic 6 and a platform 7. There is a groove 71 on the platform 7, the base 2, the traverse wedge 5 and the piezoelectric ceramic 6 are arranged in the groove 71, and the base 2 is attached to the inner wall on the left side of the groove 71, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com