Metamaterial-based directional coupler

A directional coupler and metamaterial technology, applied in the field of metamaterial-based directional couplers, can solve the problems of large insertion loss, small size, poor directivity, etc., and achieve improved directivity, reduced volume, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

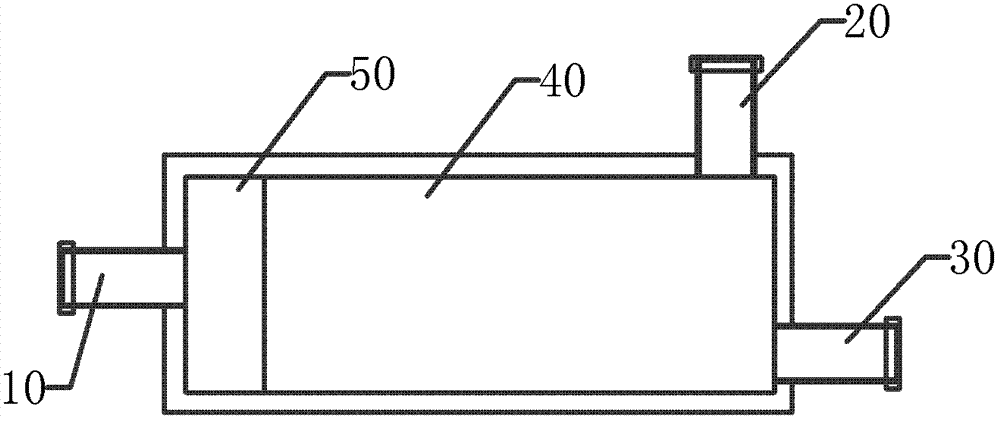

[0036] like figure 1 As shown, a metamaterial-based directional coupler, the directional coupler includes an input end 10, an output end 30, a coupling end 20, a matching module 50 and a coupling module 40, wherein the input end 10 and the One end of the matching module 50 is connected; the coupling module 40 is connected with the output terminal 30 and the coupling terminal 20 respectively; The input enters the matching module 50 and then enters the coupling module 40 , a part of the electromagnetic wave signal is directly output from the output terminal 30 , and another part of the electromagnetic wave signal is coupled to the coupling terminal 20 through the coupling module 40 and then output.

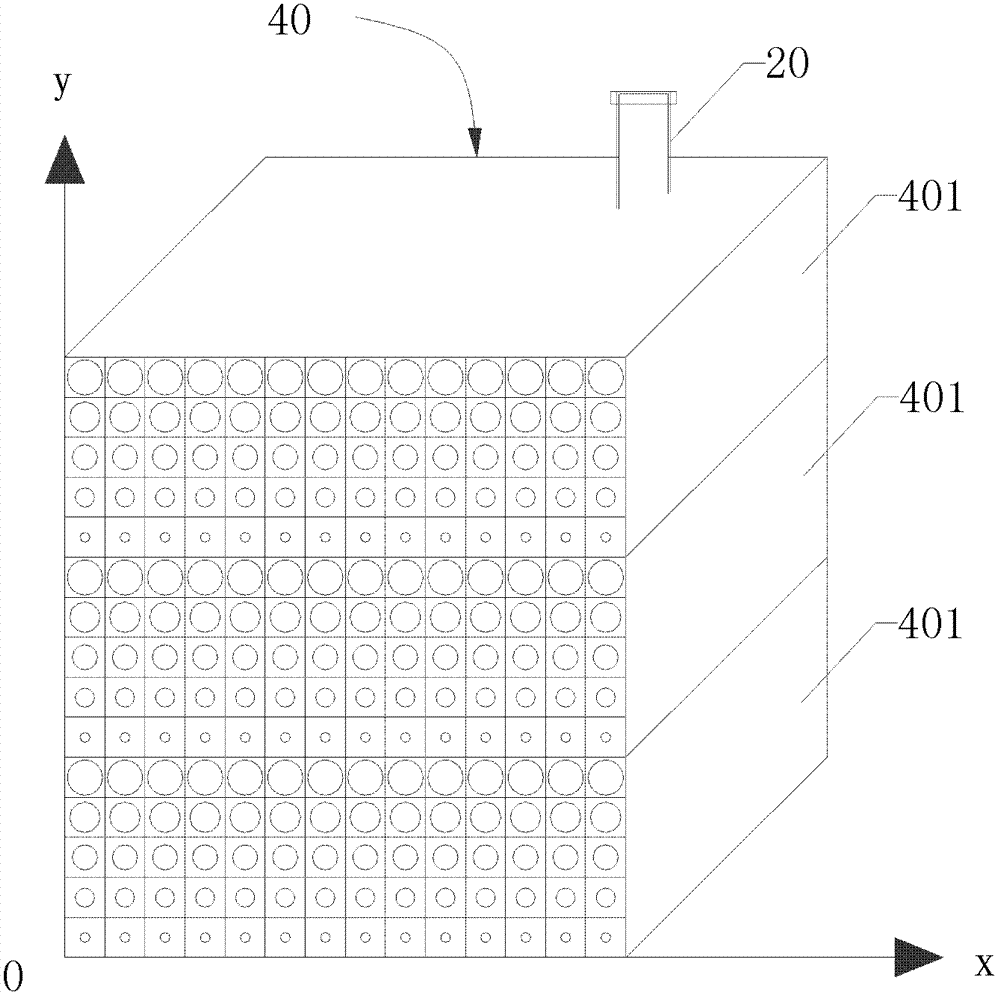

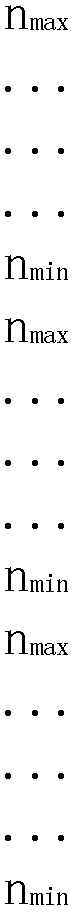

[0037] like figure 2 As shown, the coupling module 40 includes a plurality of metamaterial panels 401, and the plurality of metamaterial panels 401 are identical and have the same refractive index distribution law, that is, when the electromagnetic wave signal passes through the c...

Embodiment 2

[0053] like Figure 8 As shown, a metamaterial directional coupler includes an input terminal 10', a coupling module 40', a first coupling terminal 201, a second coupling terminal 202 and an output terminal 30'. After the electromagnetic wave signal enters the coupling module 40' from the input terminal 10', a part of the electromagnetic wave signal is directly transmitted from the output terminal 30', and a part of the electromagnetic wave signal is coupled through the coupling module 40' and then enters the first coupling terminal 201 and the second coupling terminal 201. Terminal 202. The main difference between this embodiment and Embodiment 1 is that the coupling module 40' is relatively connected together by two metamaterial panels with the same refractive index distribution, such as Figure 9 As shown, the electromagnetic wave has coupling in two directions. The oppositely connected metamaterial panels may also have different refractive indices, which depends on pract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com