Panax notoginseng polysaccharide extract and preparation method, preparations and applications thereof

A technology of Panax notoginseng polysaccharides and extracts, which can be applied in directions such as drug combinations, pharmaceutical formulations, plant raw materials, etc., can solve problems such as unfavorable comprehensive utilization of Panax notoginseng resources, waste of Panax notoginseng resources, etc., and achieve the effects of reducing costs and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

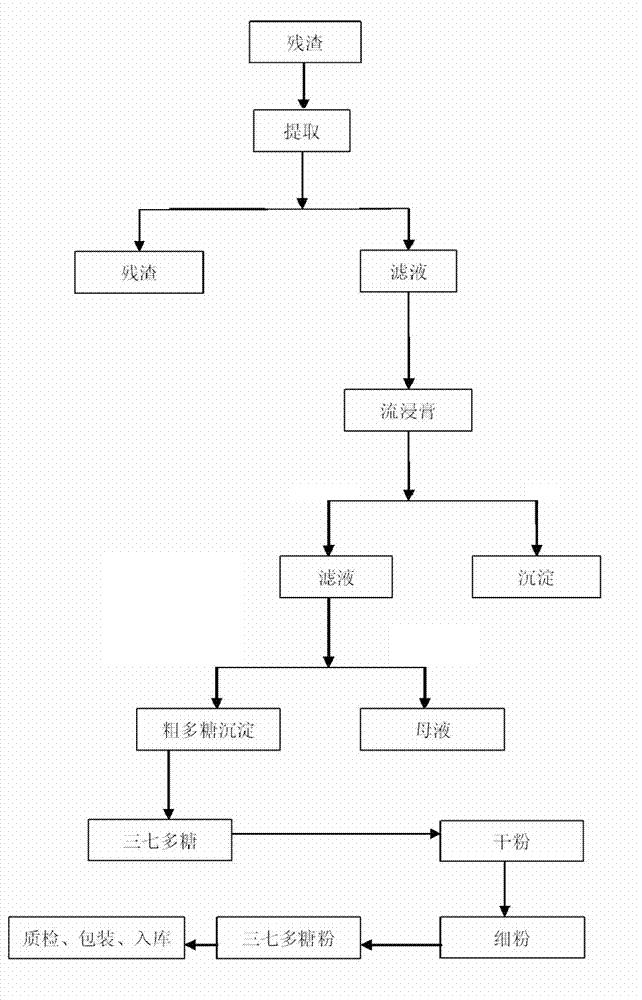

[0023] The preparation method of the Panax notoginseng polysaccharide extract of the present invention comprises the steps of extraction, concentration, refining, drying, pulverization, and inspection, specifically comprising:

[0024] The extraction is to put the waste residue after extracting the total saponins of Panax notoginseng into the extraction tank, add purified water with a volume ratio of 8~24 times, extract at a temperature of 50~60°C for 4~8 hours, and circulate leaching for 2~6 times. Filter and combine the filtrate for subsequent use;

[0025] Concentration is to concentrate the filtrate after secondary extraction to an extract with a relative density of 1.16~1.24 at a pressure of ≤0.8MPa, a temperature of ≤90°C, and a concentrated steam pressure of ≤0.3MPa;

[0026] Refining is to let the extract stand for 8~24 hours, add ethanol with a volume ratio of 3~8 times to precipitate for 8~24 hours, filter to separate the crude polysaccharide from the mother liquor, ...

Embodiment 1

[0038] Take 750 kg of Panax notoginseng, wash it, dry it until the moisture content is 10%, and crush it to a coarse powder with a particle size of 6×6~9×9mm for later use; put the coarse powder into an extraction tank, and add 60 % ethanol was leached at a temperature of 50°C for 12 hours, circulated for 5 times, filtered through a 100-mesh stainless steel screen, and the combined filtrate was used for the production of Panax notoginseng saponins, and the residue was combined for later use.

Embodiment 2

[0040] Take 750 kg of Panax notoginseng, wash it, dry it until the moisture content is 20%, and crush it to a coarse powder with a particle size of 8×8mm for later use; put the coarse powder into an extraction tank, add 90% ethanol with a volume ratio of 14 times Extract at 60°C for 8 hours, circulate leaching 3 times, filter through a 100-mesh stainless steel screen, combine the filtrates for the production of Panax notoginseng saponins, and combine the residues for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com