Liquid filling shearing bending formation method for small bending radius rectangular tube

A technology of shear bending and bending radius, which is applied in the field of liquid flushing shear bending forming of rectangular tubes with small bending radius. good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

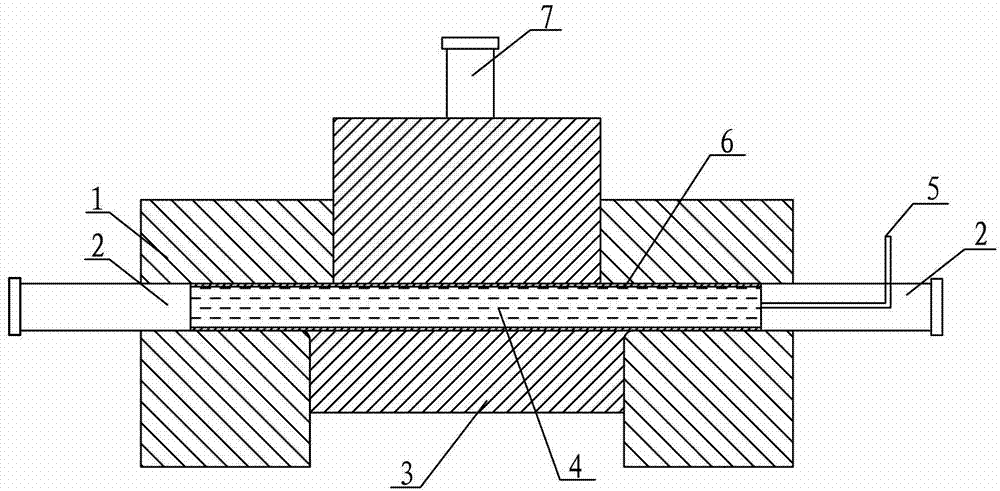

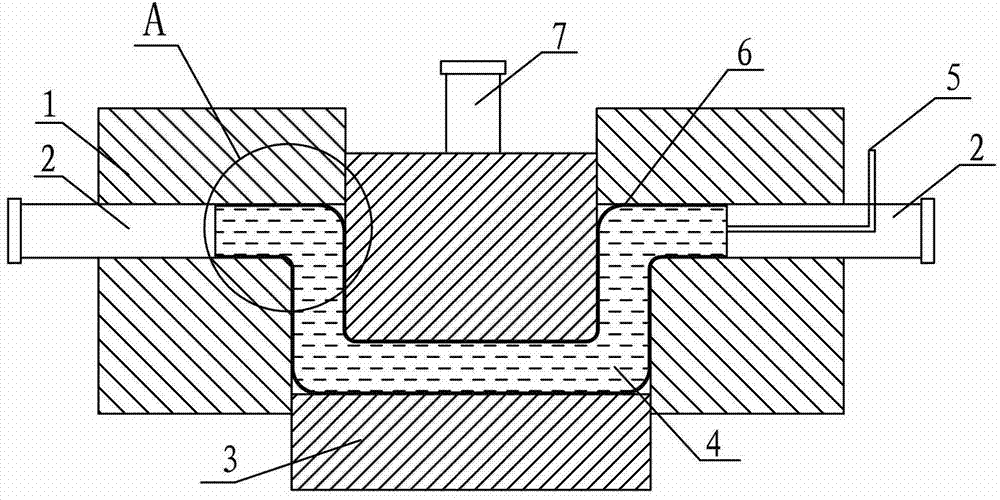

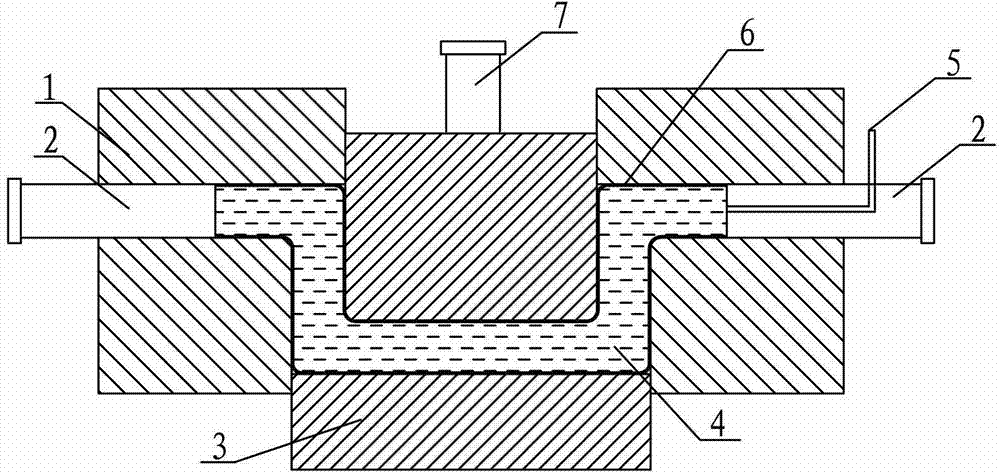

[0028] Specific Embodiment 1: In this embodiment, a liquid flushing, shearing and bending forming method for rectangular tubes with small bending radius is to place the rectangular tubes in the mold cavity, and install rectangular sealing punches on both ends of the rectangular tubes respectively. , one of the rectangular sealing punches is connected to the liquid medium input pipeline; the liquid medium is filled into the rectangular tube through the liquid medium input pipeline, and the left and right advancement of the rectangular sealing punch realizes the sealing and axial feeding of the end of the rectangular tube; After the liquid medium in the rectangular tube is pressurized to the specified value; the movable module moves tangentially along the rectangular tube relative to the fixed module, and the rectangular tube undergoes shear deformation; when the movable module moves to the specified displacement, it stops moving and the rectangular seal is The head is retracted,...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, the concrete method of the flushing shear bending forming of this embodiment is:

[0030] Step 1, filling stage: place the rectangular tube 6 in the mold cavity composed of the fixed module 1 and the movable module 3, install a rectangular sealing punch 2 on both ends of the rectangular tube 6, and place a rectangular sealing punch 2 in one of them. A medium input pipeline 5 connected to the inner cavity of the rectangular tube 6 is inserted on the head 2; the liquid medium 4 is filled into the rectangular tube 6 through the medium input pipeline 5, and the rectangular sealing punch 2 is pushed inward to realize the rectangular tube 6 The initial seal at the end of the tube 6, at this time the hydraulic pressure p1 in the tube is less than 0.1σ s , σ s is the yield strength of the material;

[0031] Step 2, forming stage: pressurize the liquid medium 4 in the rectangular tube 6...

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 5 To illustrate this embodiment, the cross section of the rectangular tube 6 in this embodiment is a square cross section, a rectangular cross section with different aspect ratios, a rectangular cross section with transitional rounded corners or a rectangular cross section without transitional rounded corners. Such arrangement is especially suitable for rectangular tubes. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com